Energy-saving and water-saving device for distributed control over industrial circulating water and control method thereof

An industrial circulating water and distributed control technology, applied in the direction of comprehensive factory control, comprehensive factory control, control/regulation system, etc., can solve the problems of water resource waste, pump flow, pressure inconsistency, electric energy waste, etc., to achieve water consumption and Reduced power consumption, high degree of automation, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

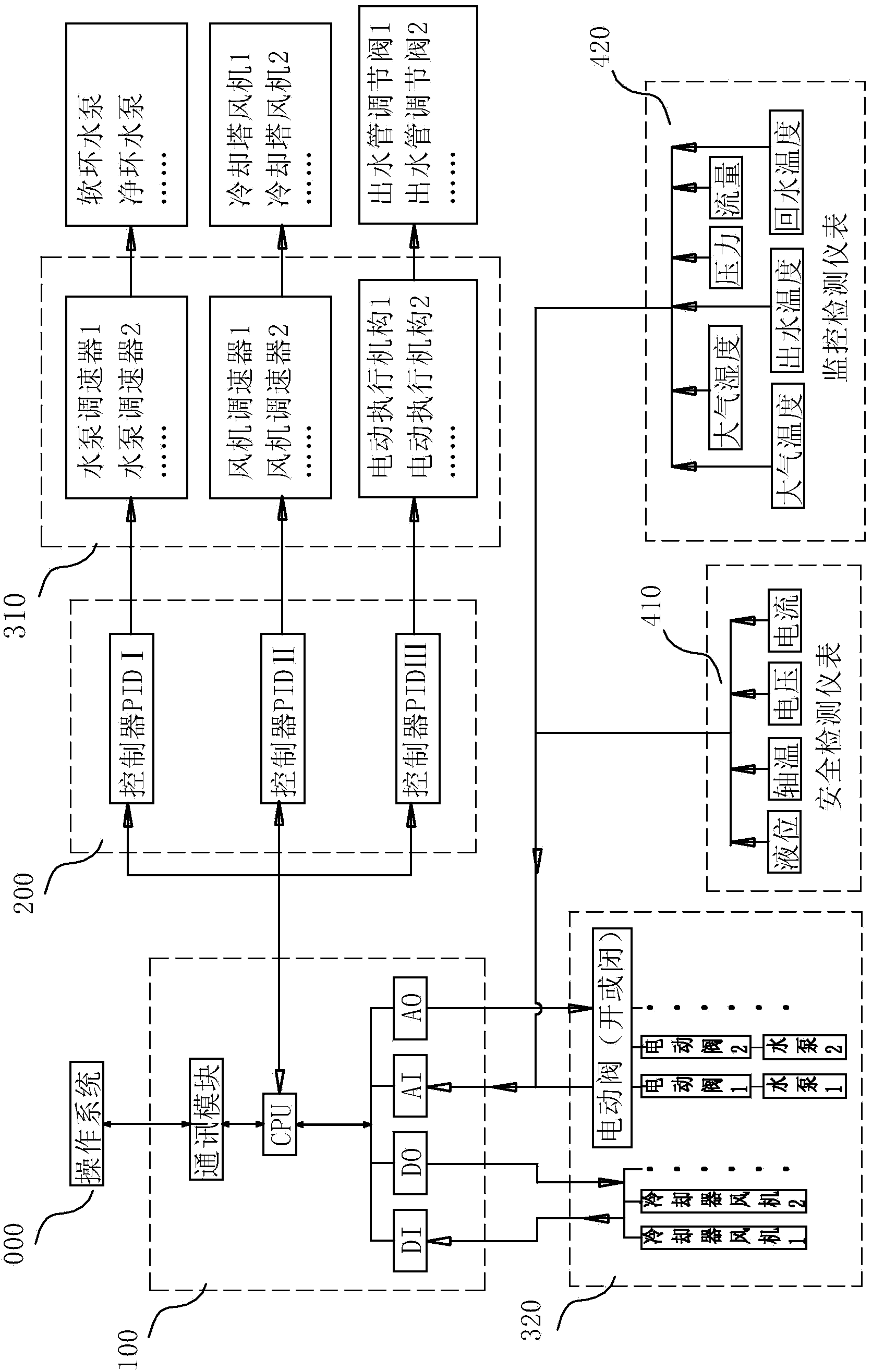

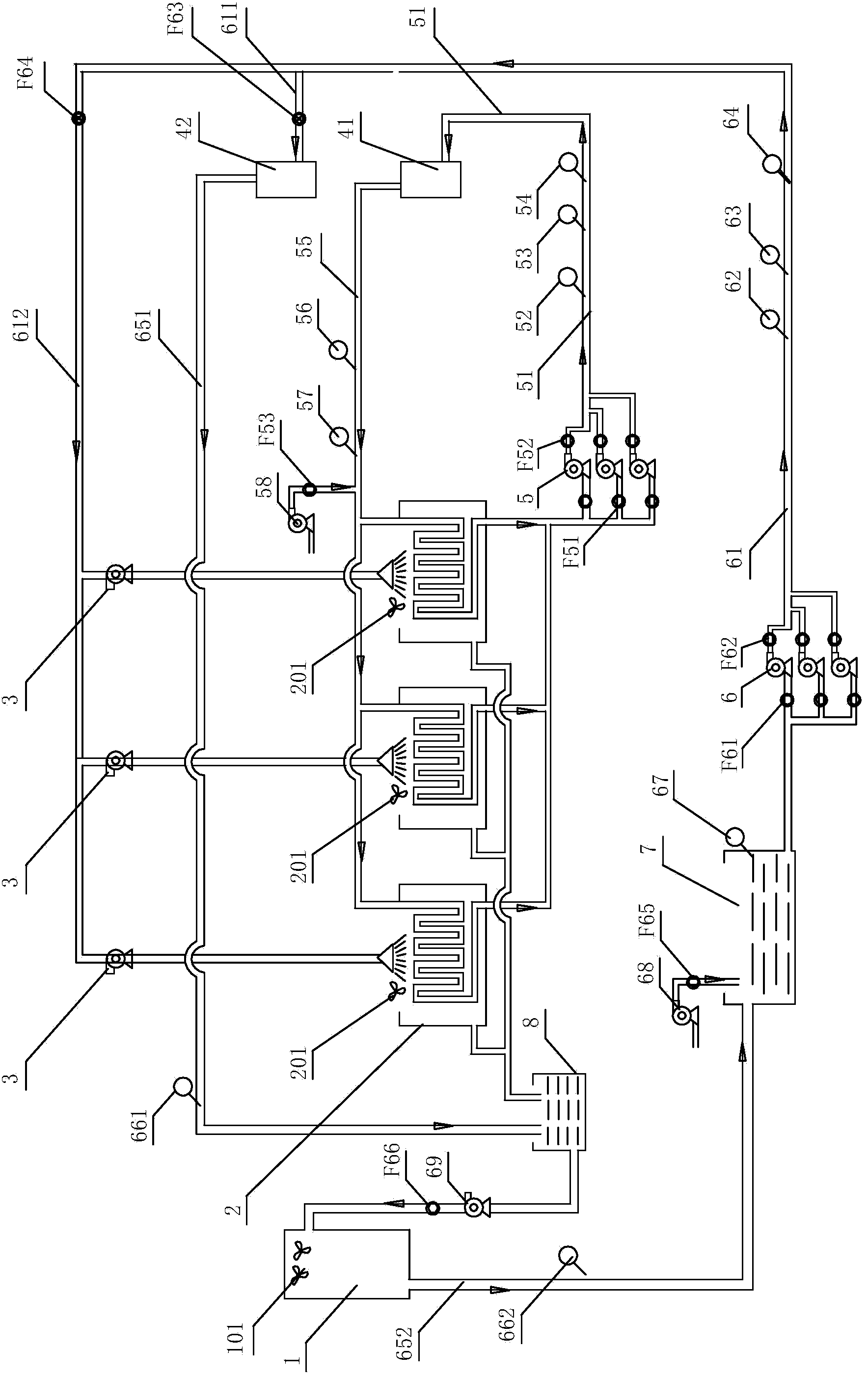

[0067] An energy-saving and water-saving device for distributed control of industrial circulating water, including an operating system 000, a central computing control system 100, a PID control system 200, and an on-site execution system Ⅰ 310. On-site execution system II 320 and on-site instrument system, the detection instruments of the on-site instrument system are distributed in the corresponding detection positions in the pipelines and circuits of the soft water closed circulation system and the clean water circulation system of industrial circulating water;

[0068] The operating system 000 is connected to the central computing control system 100 through Ethernet, and the operating system is used to input and adjust the set parameters and monitor the operating status of the entire system;

[0069] The PID control system 200 is connected to the central operation control system 100 through Ethernet, and the PID control system is used to control the action of the on-site exe...

Embodiment 2

[0089] An energy-saving and water-saving control method for industrial circulating water distribution control, the control method is composed of the above-mentioned operating system 000, central operation control system 100, PID control system 200, on-site execution system I310, on-site execution system II320 and on-site instrument system The industrial circulating water collection and distribution control energy-saving and water-saving device, through the input of the set parameters to the central operation control system, to detect the working conditions, the central operation control system will return the data and settings from the field instrument system and the field execution system Ⅱ320 Calculate, analyze and compare the parameters, and according to the results, issue execution instructions to the on-site execution system I and on-site execution system II through the DO module, AO module and PID control system, and complete the number and speed of the water pumps, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com