Motor iron core with sealing structure and combination device

A sealing structure and iron core technology, applied in the direction of electromechanical devices, electric components, magnetic circuit shape/style/structure, etc., can solve problems such as debonding, large difference in elastic modulus, damage to stator and rotor insulation, etc., to prevent the loss of paint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

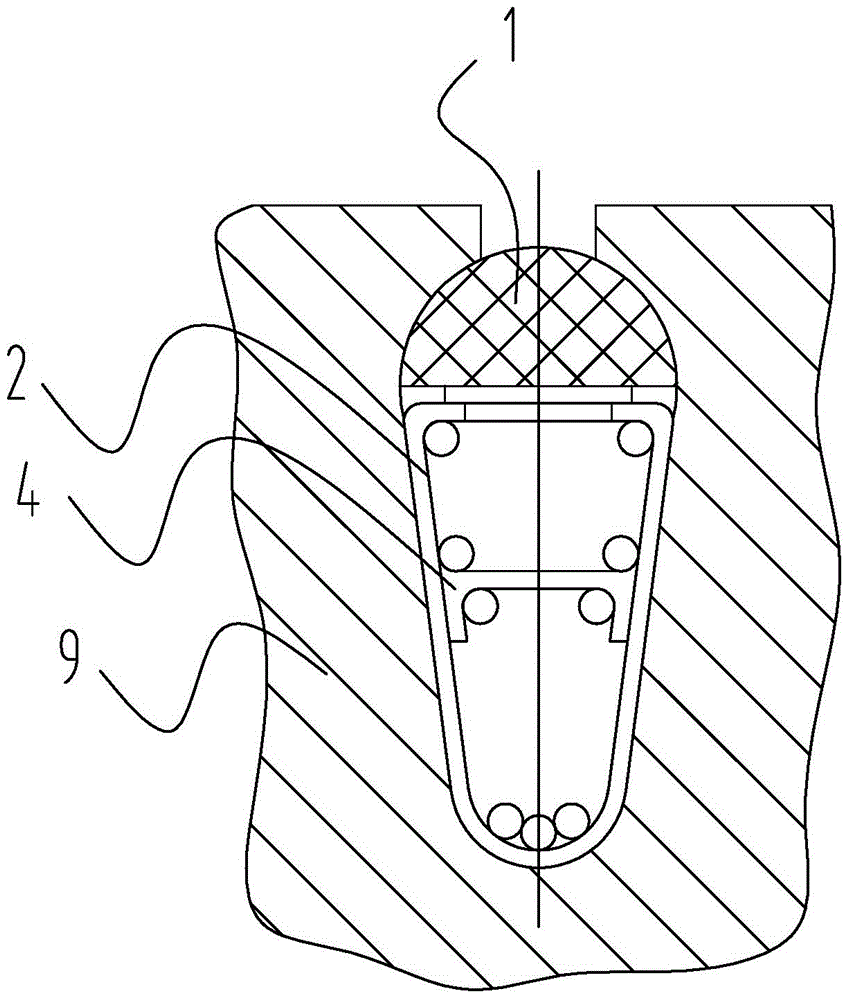

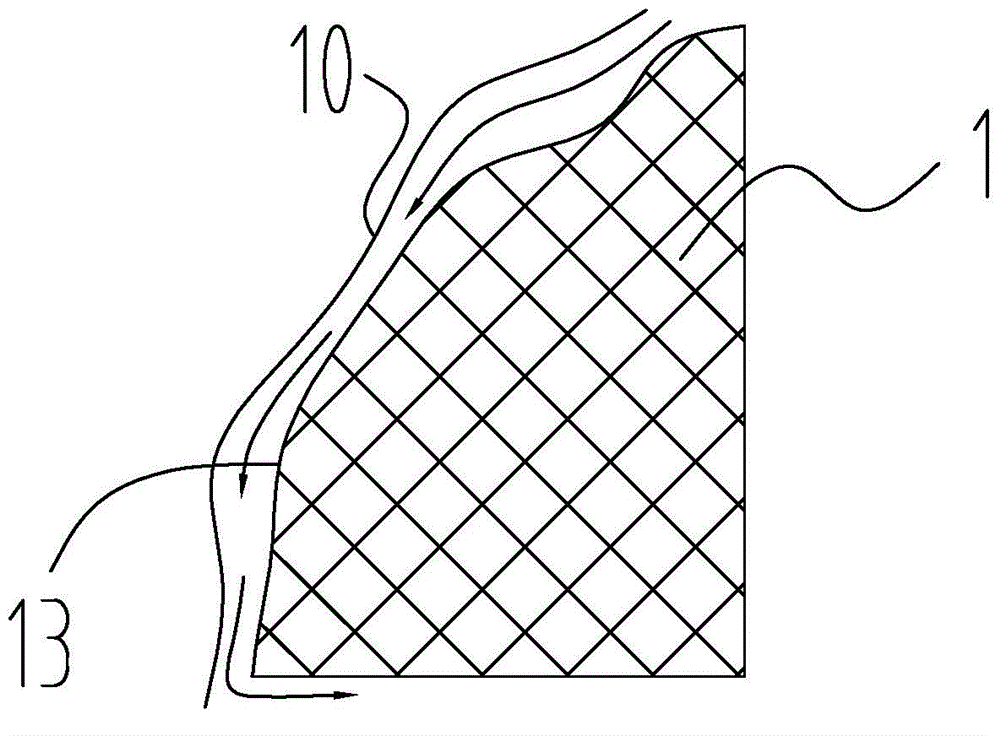

[0068] The embodiment of the present invention improves the prior art slot wedge, adds a sealing structure on the basis of the existing slot wedge, and proposes a motor slot wedge with a sealing structure. A groove is arranged on the outer wall of the slot wedge, and a thermal expansion material is arranged in the groove, and the thermal expansion material contacts the inner wall of the tooth groove of the iron core after being heated and expanded. Among them, the thermally expandable material is preferably an elastic thermally expandable material, and specifically, thermally expandable glass mat or thermally expandable rubber can be used.

[0069] The specific structure of the groove and the expansion material will be described in detail below in conjunction with the accompanying drawings, and for the convenience of description, the relevant structures will be defined and described. The part between the teeth 9 of the core is called the cogging, and the cogging of the core is...

Embodiment 2

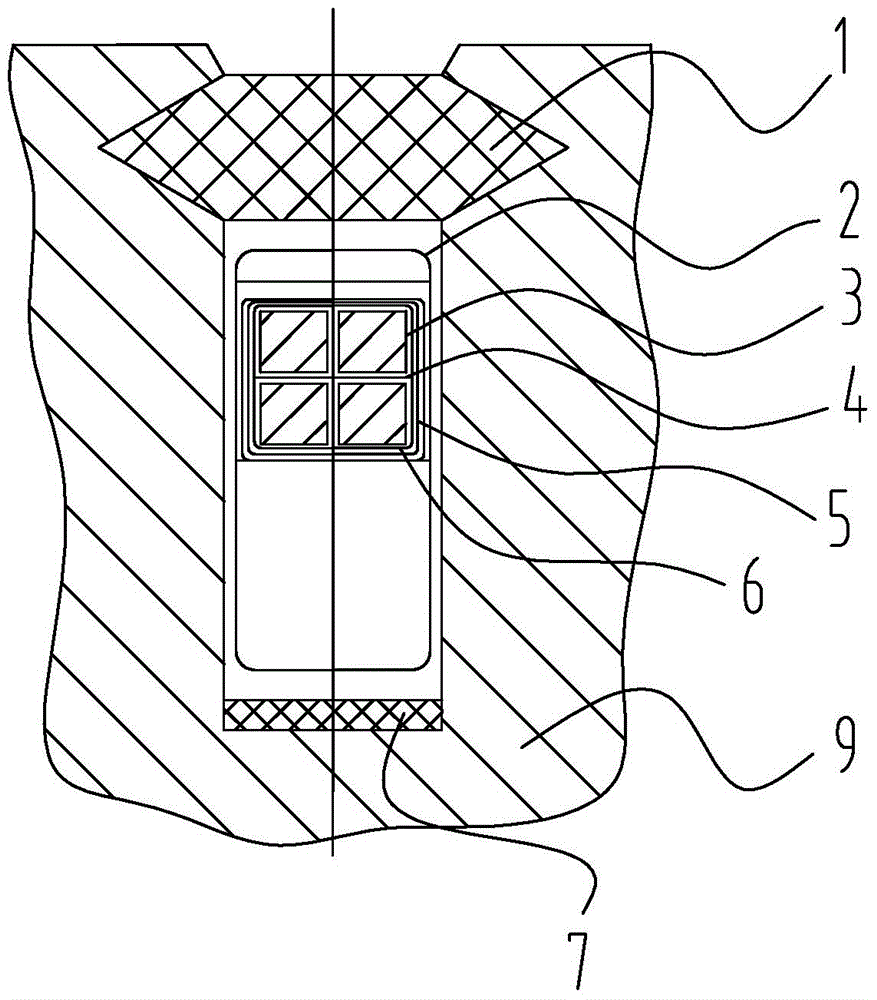

[0085] The solution provided by this embodiment is a motor core with a sealed structure, such as Figure 31 and Figure 32 shown, as a pair Figure 5 and Figure 6 The improvement of the existing iron core structure shown, the difference between this embodiment and the first embodiment is that the thermal expansion material is not arranged in the groove of the slot wedge, but directly arranged at the notch of the core tooth groove . In this embodiment, the inner wall at the bottom of the groove of the iron core slot is stepped (different from the prior art), the thermal expansion material is abutted against the surface of the lower step, and the thickness of the expansion material is higher than that between the lower step and the upper step. height difference between them. Such as Figure 32 After being heated and expanded, the heat-expandable material extends along the surface of the upper step to fill the gap between the surface of the upper step and the bottom side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com