Audio frequency device with graphene composite sound film

A composite sound film and composite sound technology, applied in the direction of diaphragm structure, non-planar diaphragm/paper cone, sensor, etc., can solve the problems of difficult installation and fixation, large vibration quality, etc., to improve installation convenience and shear resistance. The effect of increased strength, increased sensitivity and fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

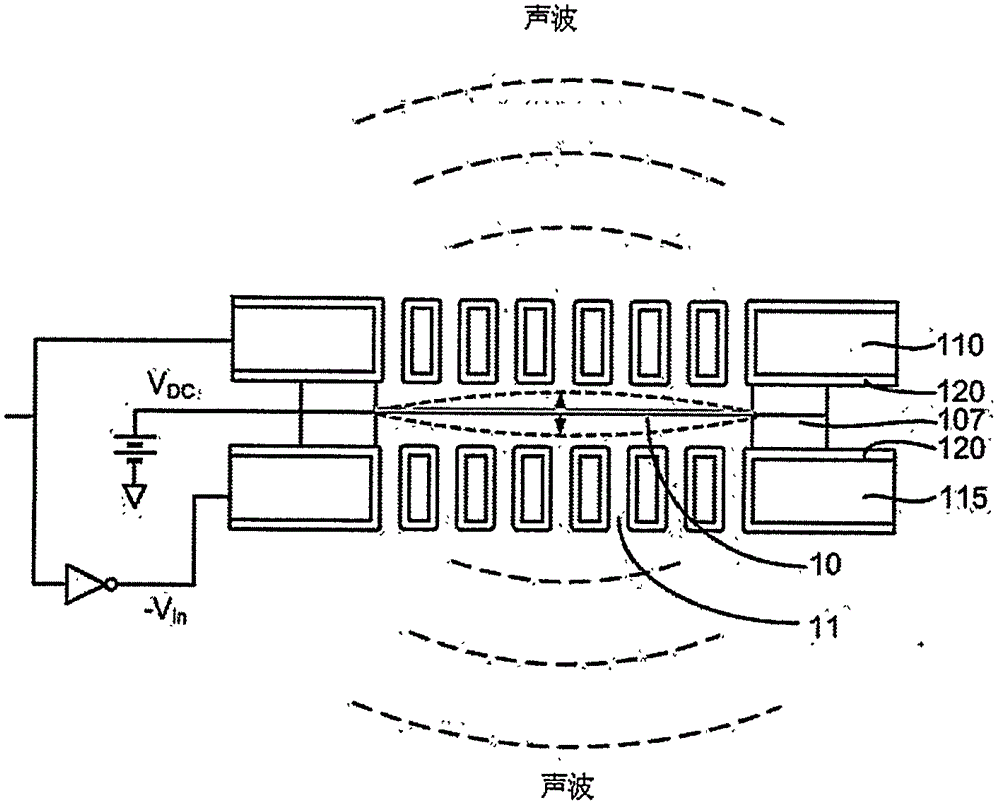

[0027] figure 1 The side view sectional view in shows an audio device according to the present invention, the audio device is used to convert electrical signals into acoustic vibrations, or convert acoustic vibrations into electrical signals, such as loudspeaker, microphone, sound sensor Or the speakers of the sound system.

[0028] The audio device has a vibrating sound film 10, which is arranged in the housing frame of the audio device, and the housing frame defines a chamber in which the vibrating sound film can vibrate, and the two sides of the housing frame have The through hole 11 for the incoming or outgoing sound wave vibration, the housing frame includes clamping bodies 107 located on the upper and lower sides in the figure, the clamping bodies 107 sandwich the vibrating sound membrane 10 to make it vibrate in the vibration chamber. The audio device also has a circuit part, which is either a driving circuit or a sensing circuit, which is respectively used to drive th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com