High-polymer-material external spring spray gun

A technology of polymer materials and spray guns, applied in the field of spray guns, can solve the problems of troublesome adjustment, large force of operation trigger, inconvenient installation, etc., and achieve the effect of easy operation and balanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

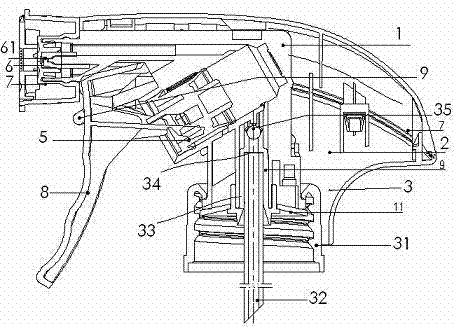

[0029] Example: such as figure 1 As shown, a polymer material external spring spray gun includes a gun body 1, a lower casing 2 and a handle 3, the front end of the handle 3 is connected with a piston barrel 4, and the piston barrel 4 is equipped with a piston 5, and the front end of the gun body 1 is equipped with a The combing head 6 is fixedly connected to the front end of the gun body 1 by the head cap 7 .

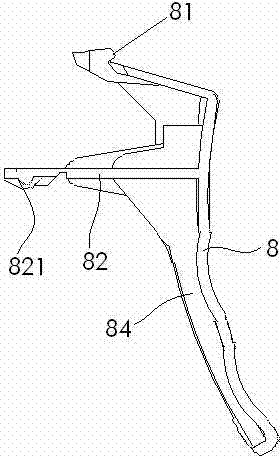

[0030] There is a trigger 8, the upper end of the trigger 8 has an inverted hook 81, the inverted hook 81 is movably overlapped with the pit 11 located at the lower part of the middle part of the gun body 1, the middle part of the trigger 8 is connected with a push rod 82, the push rod The root of 82 is orthogonally connected with trigger 8 as an integral structure, and the end of push rod 82 has boss 821, and boss 821 is rotatably connected with the socket of piston 5 rear end, as Figure 3-5 shown.

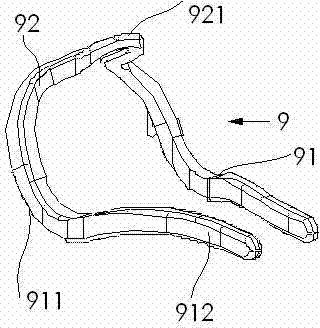

[0031] There is a U-shaped spring 9 made of polypropylene materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com