Device and method for quickly removing blockage of material conveying pipeline in production of titanium tetrachloride

A technology of titanium tetrachloride and conveying pipes, which is applied in the direction of conveyors, transportation and packaging, and conveying bulk materials. It can solve the problems of non-flowing effects of materials, blockage of shed materials, and unsatisfactory problems, and achieve good use value and application prospects. , short blockage removal time and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

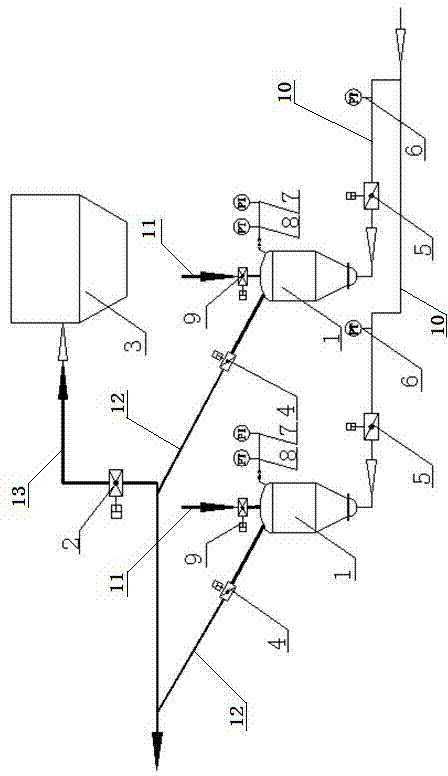

[0020] like figure 1 As shown, a device for quickly removing blockage of material conveying pipes in the production of titanium tetrachloride includes an active feeding device and a standby feeding device. The warehouse pump pressure transmitter 7 and the local pressure gauge 8, the bottom of the warehouse pump 1 is provided with an air inlet pipe 10, the air inlet pipe 10 is provided with an air inlet valve 5, and the air inlet pipe 10 is also provided with an air inlet Pressure transmitter 6, feed pipe 11 and discharge pipe 12 are provided on the top of warehouse pump 1, feed valve 9 and discharge valve 4 are respectively provided on feed pipe 11 and discharge pipe 12, discharge pipe 12 is connected with the material conveying pipeline 13, and the material conveying pipeline 13 is connected with a dust collector 3, and the end of the mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com