System for strengthening post-denitrification denitrogenation process

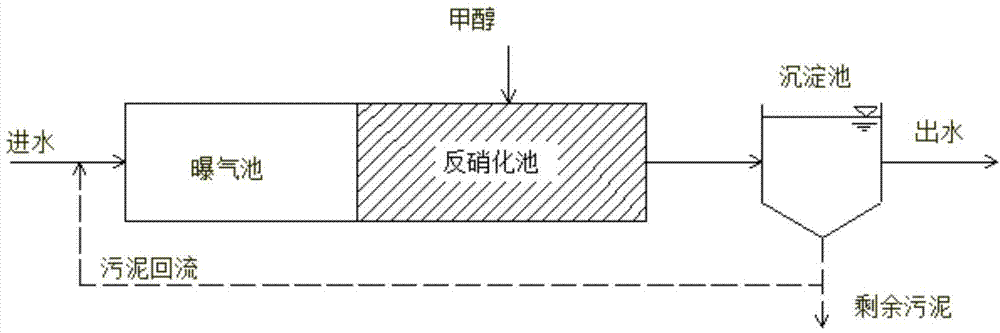

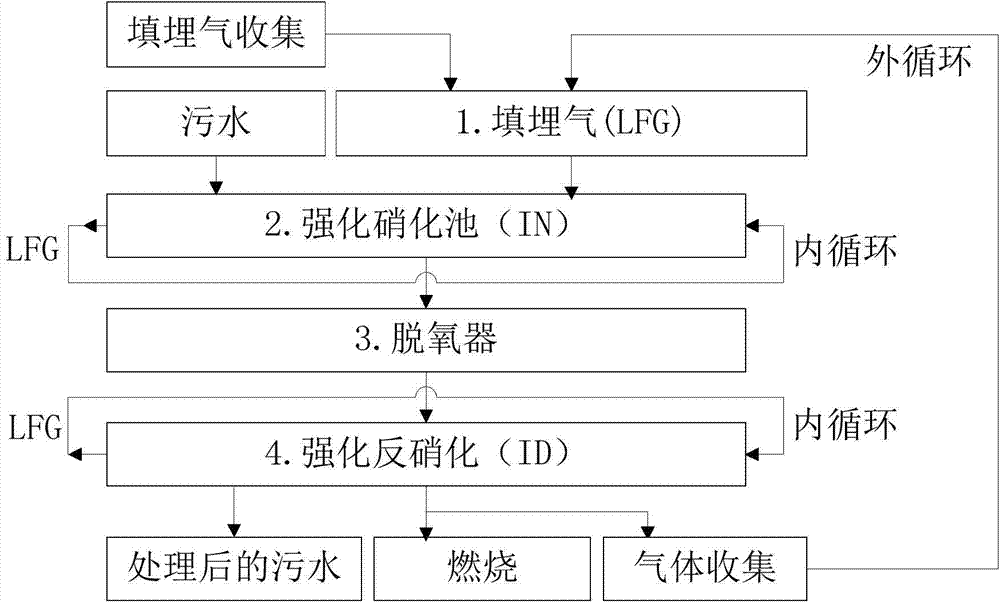

A post-denitrification and denitrification technology, applied in the field of water treatment, can solve the problems of low denitrification efficiency of the process, difficult to further improve, low operation and treatment efficiency, etc. Handling effects with stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

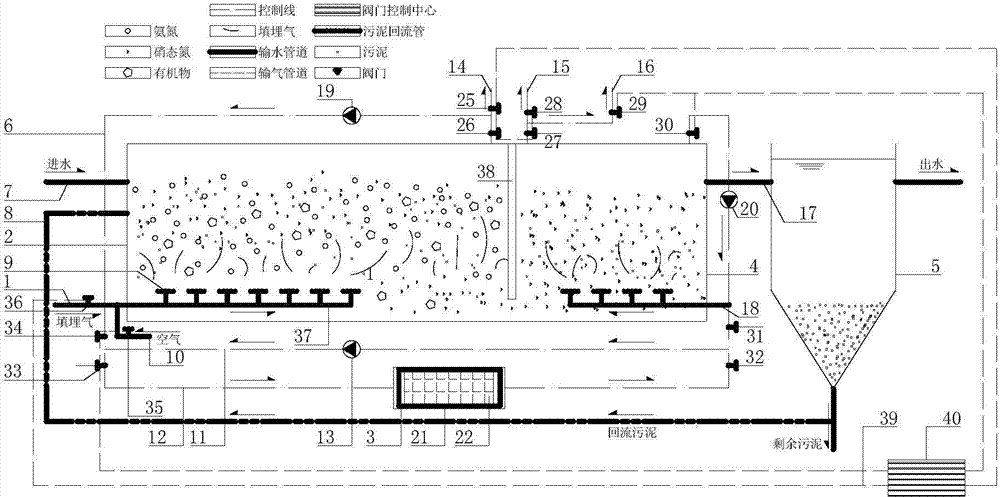

[0087] This embodiment is based on the above-mentioned technical scheme, and the waste water is treated, and the influent water quality of a city sewage is BOD 5 : 240-330mg / L, NH 3 -N: 34-43mg / L, TN: 42-55mg / L, daily processing capacity 3000m 3 / d.

[0088] IN pool 2 length × width × height: 30m × 10m × 3.5m effective height 3m, ID pool 4 length × width × height: 10m × 10m × 3.5m effective height 3m, the distance between the partition wall 38 and the pool bottom is 0.6 of the pool height m; the IN tank aeration pipe 37 in the IN tank 2 of the enhanced nitrification tank extends 20 m into the tank; the average gas supply volume of the landfill gas inlet pipe 1 in the pre-acclimation and treatment stages of the IN tank 2 is 680 m 3 / h, wherein the mixing ratio of landfill gas and air is 2:1, the proportion of gas circulating in the IN pool gas internal circulation pipe 6 is 50%, and the hydraulic retention time is 9.6h; The average gas supply volume of buried gas intake pipe...

Embodiment 2

[0090] In this embodiment, based on the above technical scheme, a certain livestock and poultry wastewater is treated, and the average water quality is COD Cr 2530mg / L, TN640mg / L, NH4 + -N280mg / L, daily processing capacity 5000m 3 / d.

[0091] IN pool 2 length × width × height: 30m × 10m × 3.5m effective height 3m, ID pool 4 length × width × height: 10m × 10m × 3.5m effective height 3m, the distance between the partition wall 38 and the pool bottom is 0.6 of the pool height m; the aeration pipe 37 of the IN tank in the IN tank 2 of the enhanced nitrification tank extends 20 m into the tank; the average gas supply volume of the landfill gas inlet pipe 1 in the pre-acclimation and treatment stages of the IN tank 2 is 900 m 3 / h, wherein the mixing ratio of landfill gas and air is 2:1, the proportion of gas circulating in the IN tank gas internal circulation pipe 6 is 80%, and the hydraulic retention time is 5.76h; The average gas supply volume of buried gas intake pipe 1 is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com