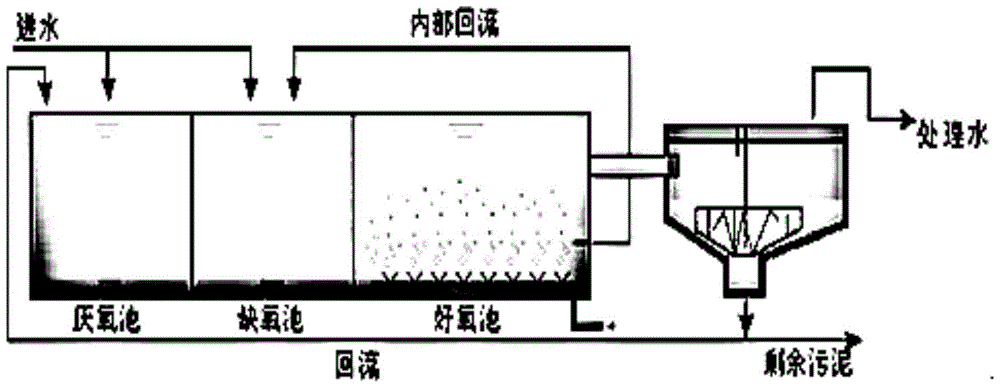

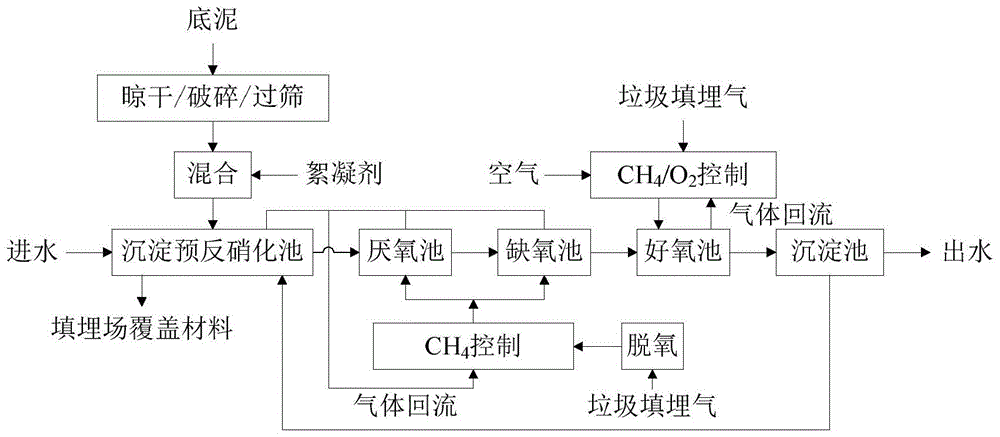

based on a 2 System and method for synchronous denitrification, phosphorus and algae reduction in /o process

A simultaneous denitrification, phosphorus, and treatment system technology, applied in the field of simultaneous denitrification, phosphorus, and algae reduction treatment systems, can solve the problem of difficulty in further improving nitrogen removal efficiency, poor winter operation and treatment effects, and asynchronous denitrification, phosphorus, and algae reduction, etc. problems, to achieve the effect of reusing waste, reducing secondary pollution, and enriching the number of populations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] Further, the preparation method of the reinforced flocculant in the step 1 comprises the following steps:

[0068] Step 1.1, collecting the sediment produced by the dredging project and having a water depth greater than 1.0-1.5m;

[0069] In step 1.2, the bottom mud collected in step 1.1 is naturally air-dried for several days, then crushed and passed through a 2mm sieve to obtain a bottom mud sample with a particle size of less than 2mm;

[0070] In step 1.3, uniformly mix the sediment sample obtained in step 1.2 with a typical flocculant, and the mixing ratio of the sediment sample to the typical flocculant is between 5:1 and 10:1.

[0071] Further, the natural air-drying temperature in the step 1.2 is 25±1° C., and the natural air-drying time is 7 days.

[0072] Further, the typical flocculant is any one or more of the following:

[0073] Polyaluminum Chloride (PAC);

[0074] Basic aluminum chloride;

[0075] Aluminum sulfate;

[0076] Polyacrylamide (PAM);

[...

Embodiment 1

[0097] In this embodiment, wastewater treatment is carried out on the water of a certain lake. The lake water is in a state of eutrophication and gradually transforms into heavy eutrophication. / L, nitrate nitrogen 0.3mg / L, total nitrogen 25.8mg / L, total phosphorus 0.33mg / L, chlorophyll 58.4mg / L, suspended matter 34.00mg / L.

[0098] Aerobic pool size, length × width × height: 50m × 6m × 5.0m (effective height 4.5m), volume V 1 : 1500m 3 , sludge age 9d, hydraulic retention time 3.9h; anoxic tank size, length × width × height: 41m × 6m × 5.0m (effective height 4.5m), volume V 1 : 1230m 3 , the hydraulic retention time is 3.3h; the size of the anaerobic tank, length × width × height: 20m × 6m × 5.0m (effective height 4.5m), volume V 1 : 600m 3 , the hydraulic retention time is 1.5h; the size of the pre-sedimentation pre-denitrification tank, length × width × height: 6m × 5m × 4.0m (effective height 3.5m), volume V 1 : 120m 3 ;Under this operating condition, the effluent wa...

Embodiment 2

[0100] In this embodiment, a simulated lake water is treated, and the density of Microcystis aeruginosa algae is about 8×10 in the simulated lake water. 7 cells / L, chlorophyll a500mg / m 3 , total nitrogen 12mg / L, total phosphorus 0.8mg / L.

[0101] Aerobic pool size, length × width × height: 50m × 6m × 5.0m (effective height 4.5m), volume V 1 : 1500m 3 , sludge age 9d, hydraulic retention time 3.9h; anoxic tank size, length × width × height: 41m × 6m × 5.0m (effective height 4.5m), volume V 1 : 1230m 3 , the hydraulic retention time is 3.3h; the size of the anaerobic tank, length × width × height: 20m × 6m × 5.0m (effective height 4.5m), volume V 1 : 600m 3 , the hydraulic retention time is 1.5h; the size of the pre-sedimentation pre-denitrification tank, length × width × height: 6m × 5m × 4.0m (effective height 3.5m), volume V 1 : 120m 3 ;Under this operating condition, the effluent water quality of the sedimentation tank is: the removal rate of chlorophyll a is 100%, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com