Manufacturing method of integrated multi-functional water producer

A water generator and multi-functional technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., to achieve remarkable sewage discharge efficiency, inhibit microbial reproduction, and improve temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

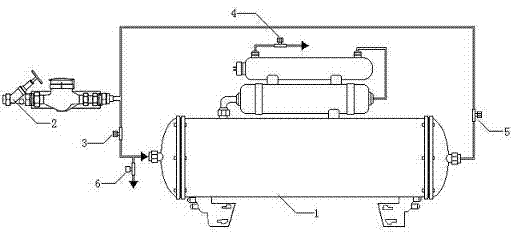

[0012] figure 1 Show the situation that the water treatment device of the present invention is equipped with an ultraviolet sterilizing device, as for urban and rural household use, then directly tap water is introduced, and sent into the device of the present invention through main valve 2 and valve 3 for filtration and sterilizing treatment, The treated water is exported to the outside through the valve 4 for use.

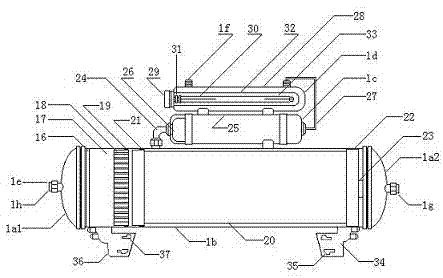

[0013] figure 2 Among them, the filter device 1 is a closed container composed of a cylinder body 1b, a left end cover 1a1, a right end cover 1a2, a rear filter element housing 1c and an ultraviolet germicidal lamp housing 1d, the cylinder body 1b, a left end cover 1a1, a right end cover 1a2 and a rear filter element The shell 1c and the ultraviolet germicidal lamp shell 1d are spirally connected. The left side of the airtight container is provided with a honeycomb ceramic filter element 18 (aperture is 0.35mm), and the groove on the outer wall of the honeycomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com