Horizontal concentric double-layer sludge thin-layer drying equipment

A double-layer, sludge technology, used in dewatering/drying/concentrating sludge treatment, runoff/rainwater treatment, etc., can solve the problems of large heat loss, high dust volume, long axial length, etc., to improve the layout, shorten the Effect of Axial Length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

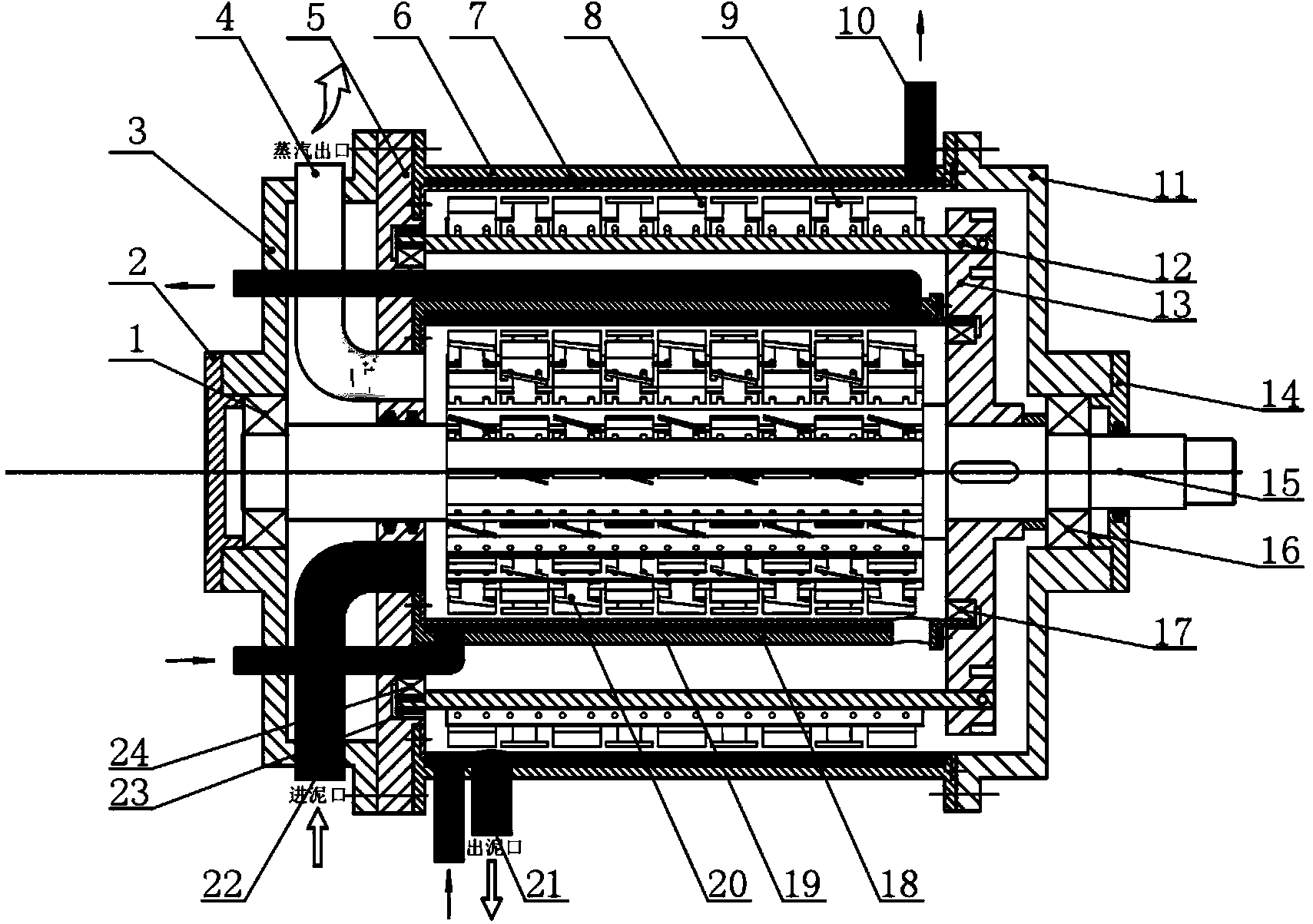

[0017] A horizontal concentric double-layer sludge thin-layer drying equipment involved in this embodiment is an example of a sewage treatment plant treating sludge with a water content of 85% to 70%. The overall structure of the equipment is as follows figure 1 Shown:

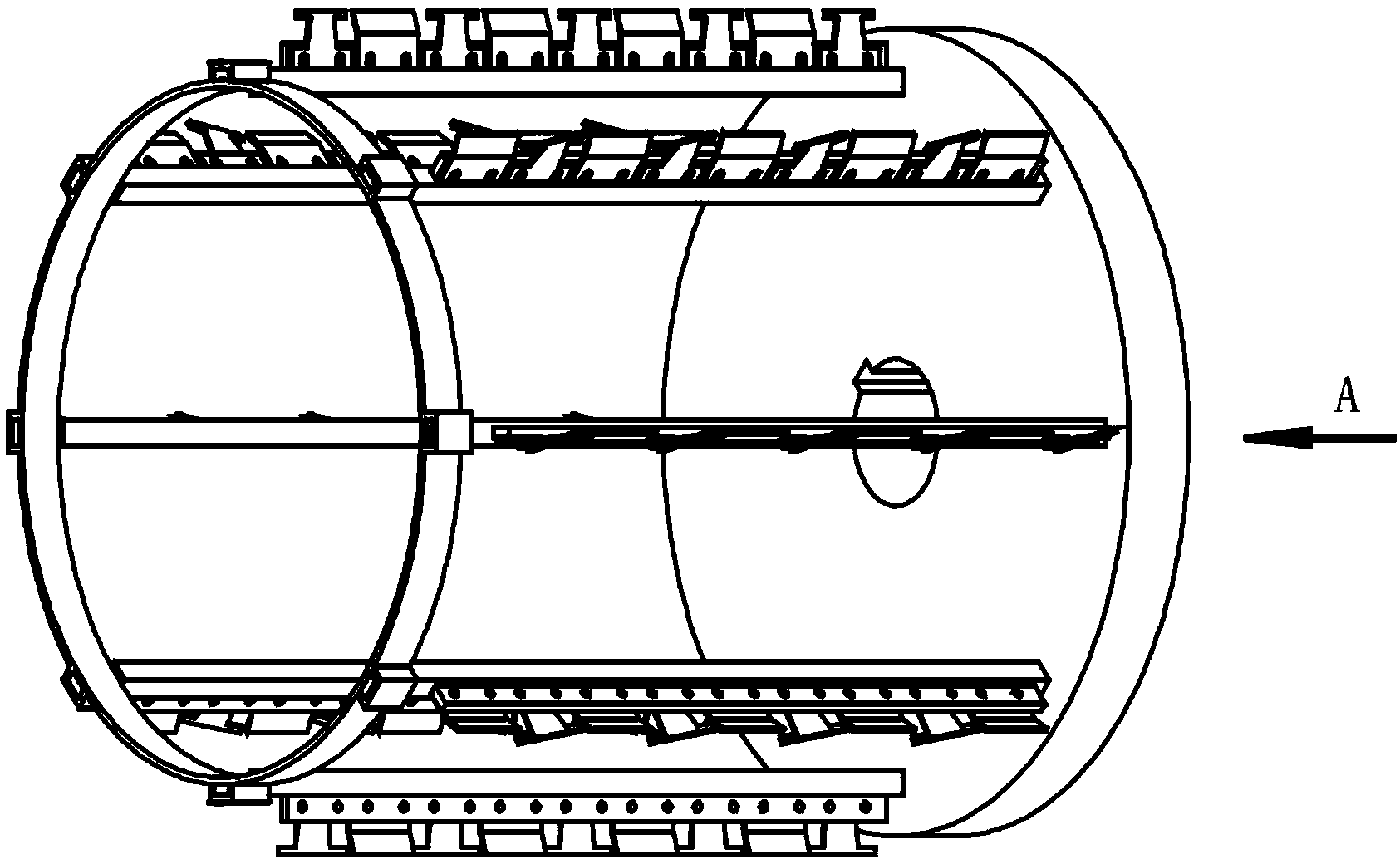

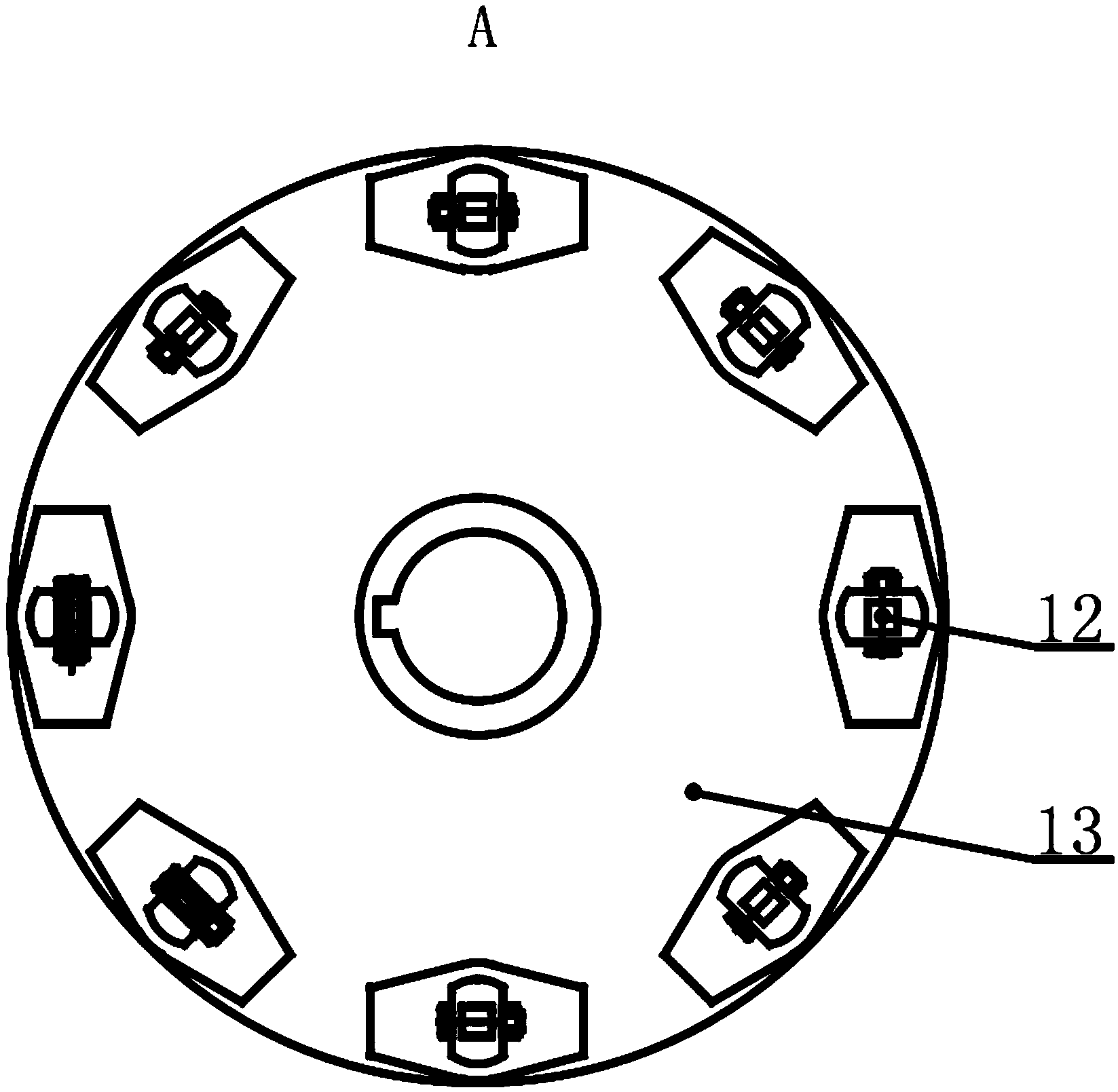

[0018] This embodiment consists of a left bearing 1, a left bearing cover 2, a left end cover 3, a steam pipe 4, a support wall 5, an outer evaporator outer cylinder 6, an outer evaporator inner cylinder 7, a horizontal scraper 8, an inclined scraper A 9, Heat conduction oil pipe 10, right end cover 11, scraper arm 12, rotating wall 13, right bearing cover 14, rotating shaft 15, right bearing 16, inner evaporator support bearing 17, inner evaporator outer cylinder 18, inner evaporator inner cylinder 19, Inclined scraper B 20, mud outlet pipe 21, mud inlet pipe 22, scraper arm restraint ring 23, scraper arm support bearing 24;

[0019] The outer cylinder 6 of the outer evaporator and the inner cylinder 7 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com