A kind of heat treatment method of copper chromium alloy for high voltage switch

A heat treatment method, copper-chromium alloy technology, applied in the field of heat treatment of alloy materials, can solve problems that affect product quality and performance, and performance parameters are difficult to greatly improve, and achieve the effect of improving quality and performance and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

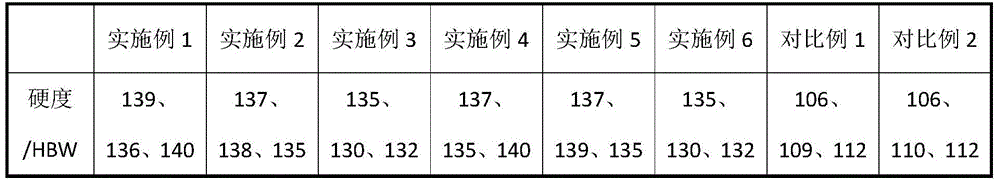

Examples

Embodiment 1

[0017] The heat treatment method of copper chromium alloy for high voltage switch in the present embodiment comprises the following steps:

[0018] (1) Copper-chromium alloy (see Table 1 below for specific composition) profiles are subjected to solid solution treatment after blanking, kept at a temperature of 1035°C for 60 minutes, then quickly quenched into flowing clear water and cooled to room temperature for later use;

[0019] (2) Take the material after solid solution treatment and carry out aging treatment immediately, keep it warm for 120 minutes at a temperature of 470° C., and cool it naturally in air to room temperature.

Embodiment 2

[0021] The heat treatment method of copper chromium alloy for high voltage switch in the present embodiment comprises the following steps:

[0022] (1) Copper-chromium alloy (see Table 1 below for specific composition) profiles are subjected to solid solution treatment after blanking, kept at a temperature of 1040°C for 50 minutes, then quickly quenched into flowing clear water and cooled to room temperature for later use;

[0023] (2) Take the material after solid solution treatment and perform aging treatment immediately, keep it warm for 130 minutes at a temperature of 460° C., and cool it naturally in the air to room temperature.

Embodiment 3

[0025] The heat treatment method of copper chromium alloy for high voltage switch in the present embodiment comprises the following steps:

[0026] (1) Copper-chromium alloy (see Table 1 below for specific composition) profiles are subjected to solid solution treatment after blanking, kept at a temperature of 1030°C for 70 minutes, then quickly quenched into flowing clear water and cooled to room temperature for later use;

[0027] (2) The material after solid solution treatment was taken to be subjected to aging treatment immediately, kept at a temperature of 480° C. for 110 minutes, and naturally cooled to room temperature in air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com