Steel and iron blackening agent

A technology of iron and steel blackening agent and pretreatment liquid, applied in the direction of metal material coating process, etc., can solve the problems of insufficient corrosion resistance and poor gloss of the film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A steel blackening agent, comprising a pretreatment liquid and a blackening liquid, wherein:

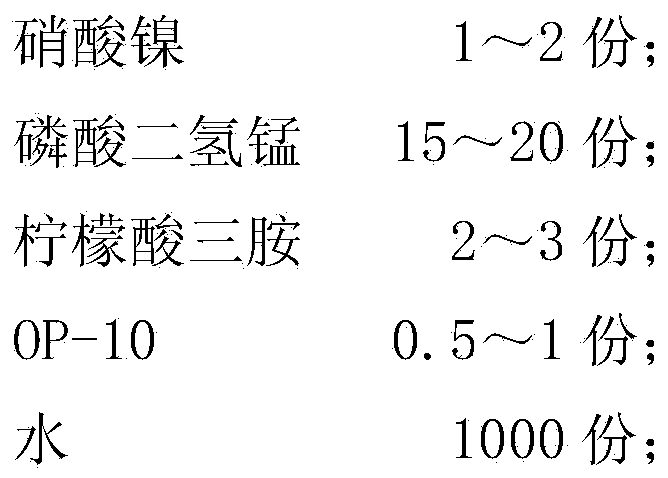

[0022] The pretreatment liquid is prepared from the following raw materials in parts by weight:

[0023] Na 2 S 3 copies;

[0024] NH 4 h 2 PO 4 5 copies;

[0025] 1000 parts of water;

[0026] The meter adjustment time of the pretreatment liquid is 1 to 2 minutes;

[0027] The blackening liquid is prepared from the following raw materials in parts by weight:

[0028]

[0029] The temperature of the blackening solution is 20-30°C, and the blackening time is 5-10 minutes.

[0030] The process of applying the pretreatment liquid and blackening liquid in this embodiment to blackening is as follows: iron and steel parts→oil removal→rust removal→hot water washing→cold water washing→acid activation→cold water washing→pretreatment liquid surface adjustment→blackening liquid Blackening at room temperature→washing in cold water→drying→post-processing→drying→finished produc...

Embodiment 2

[0035] A steel blackening agent, comprising a pretreatment liquid and a blackening liquid, wherein:

[0036] The pretreatment liquid is prepared from the following raw materials in parts by weight:

[0037] Na 2 S 4 copies;

[0038] NH 4 h 2 PO 4 3 copies;

[0039] 1000 parts of water;

[0040] The meter adjustment time of the pretreatment liquid is 1 to 2 minutes;

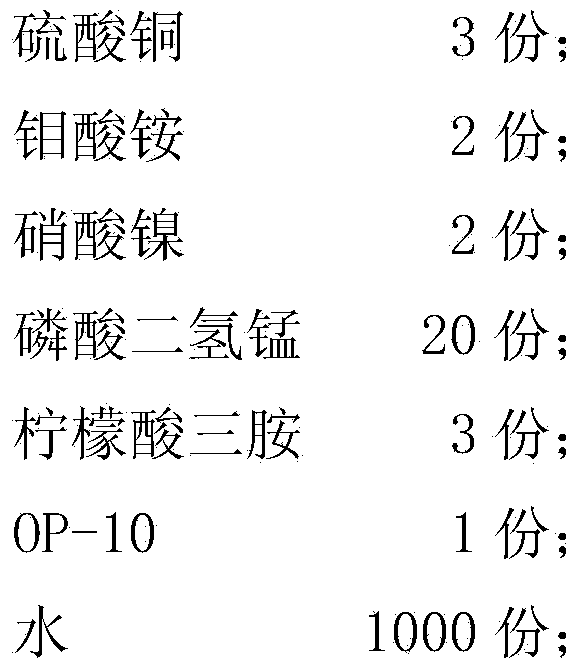

[0041] The blackening liquid is prepared from the following raw materials in parts by weight:

[0042]

[0043] The temperature of the blackening solution is 20-30°C, and the blackening time is 5-10 minutes.

[0044] The process of applying the pretreatment liquid and blackening liquid in this embodiment to blackening is as follows: iron and steel parts→oil removal→rust removal→hot water washing→cold water washing→acid activation→cold water washing→pretreatment liquid surface adjustment→blackening liquid Blackening at room temperature→washing in cold water→drying→post-processing→drying→finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com