Electro-fused magnesia furnace power consumption remote monitoring system and method

A technology of remote monitoring and fused magnesia furnace, applied in transmission system, electrical program control, general control system, etc., can solve the problem of real-time data provision, inability to provide remote monitoring function for enterprise managers and scientific researchers, and energy consumption monitoring space range Limitations and other issues, to achieve the effect of improving production technology and technology, facilitating the optimal allocation of energy, and improving the level of energy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

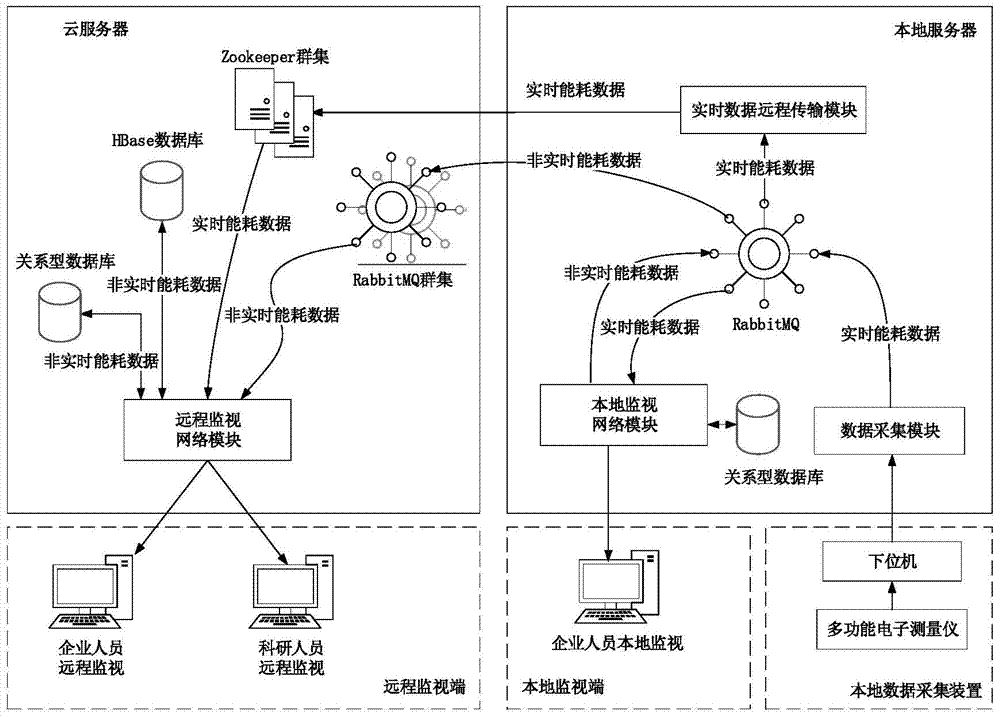

[0044] The remote monitoring system for the energy consumption of the electric fused magnesium furnace in this embodiment, such as figure 1 As shown, including: local data acquisition device, local server, cloud server;

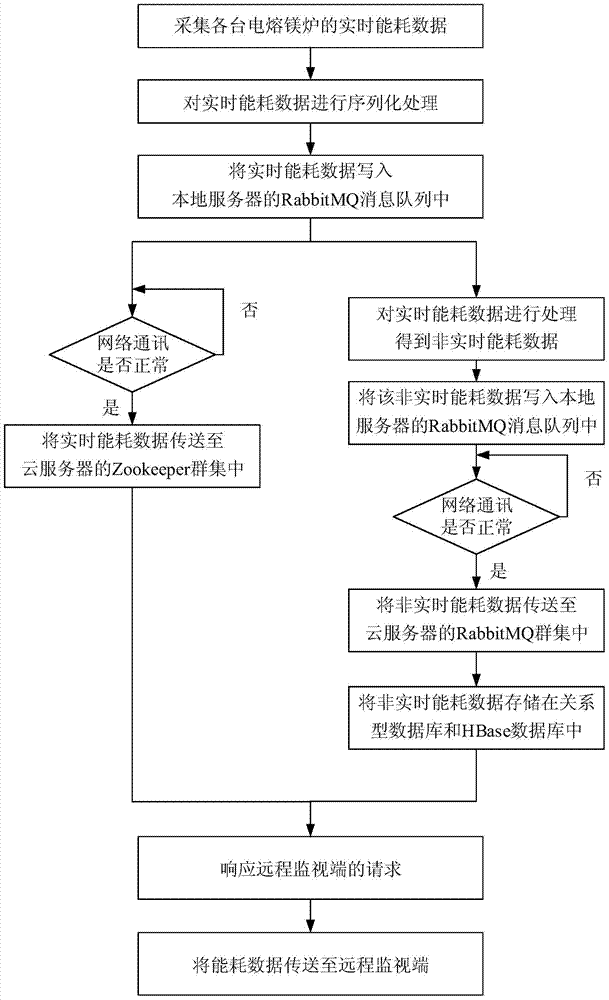

[0045]Among the local data acquisition devices in the present embodiment, including 5 multifunctional electronic measuring instruments whose models are ME96NSR, what the lower computer adopts is the Mitsubishi Q series PLC whose CPU model is Q03UD; The data acquisition module, the RabbitMQ that supports the advanced message queue protocol, the local monitoring network module that can respond to the requests of IE and Chrome browsers, the real-time data remote transmission module developed based on C# language, and the relational database version of SQL Server 2012; In the implementation mode, the cloud server includes a Zookeeper clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com