Flat plate thin pipe type electrode pole plate

A thin, plate technology, used in lead-acid battery electrodes, electrode carriers/current collectors, etc., can solve the problems of long charging time, small specific energy, and low utilization rate of active materials, and achieve high utilization rate of active materials. specific energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the accompanying drawings and typical embodiments below, but the embodiments are only for illustration and cannot limit the scope of the present invention.

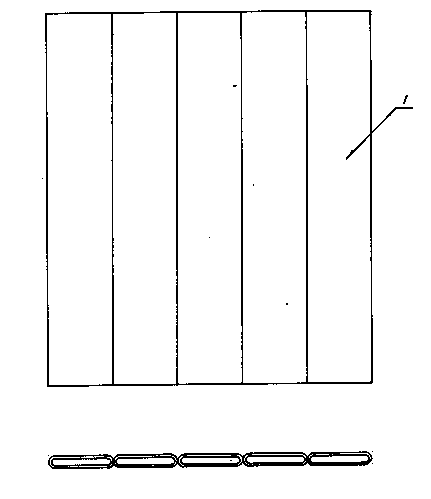

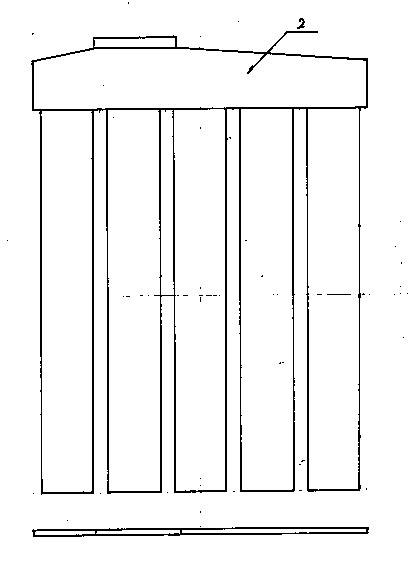

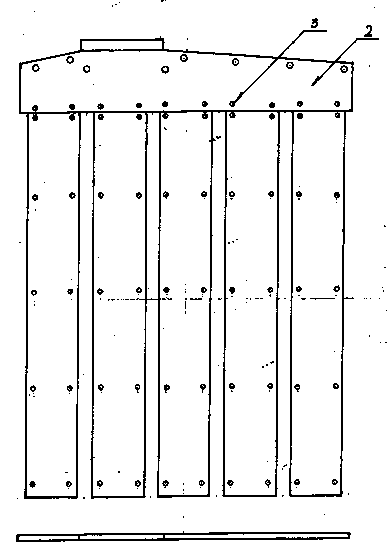

[0021] A flat strip-shaped thin tubular electrode plate, including a positive electrode plate, the positive electrode plate is provided with a row tube 1 and a grid 2 sleeved in the row tube 1 and filled between the row tube 1 and the grid 2 The positive electrode mixture 6; the row pipe 1 is a thin flat strip and is set on the grid 2; the grid 2 is composed of several flat strip thin alloy lead strips 8, and the grid 2 is provided with There are several reinforcing rib holes 3, and the reinforcing rib holes 3 are connected by reinforcing ribs 4.

[0022] It also includes connecting ribs 7, which are vertically arranged at the bottom of the grid 2 and sealed by the back cover. When the entire electrode plate is charged and discharged, it can form a whole pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com