Method for removing radioactive iodine from gas cooled reactor

A technology of radioactive iodine and gas-cooled reactors, applied in the direction of radioactive purification, separation methods, chemical instruments and methods, etc., can solve the problems of low temperature of adsorbents and unsuitability for high-temperature gas-cooled reactors, and achieve stable performance and decontamination Good effect, good pressure stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of 15%Ag / 13X adsorbent

[0037] Weigh 9.45g AgNO 3 , dissolved in 200mL deionized water, and stirred evenly. Weigh 40g of 13X molecular sieve (20 / 60 mesh powder particles), drop into the above AgNO 3 In the solution, stirred and impregnated at room temperature for 12 hours, then evaporated to remove water, and dried at 110°C for 12 hours. The dried sample was placed in a muffle furnace, raised from room temperature to 450 °C at a rate of 2 °C / min, and then naturally cooled at 450 °C for 2 hours to obtain a 15% Ag / 13X adsorbent (15% Ag / 13X mass percentage), marked as 15%Ag / 13X (450C / 2h).

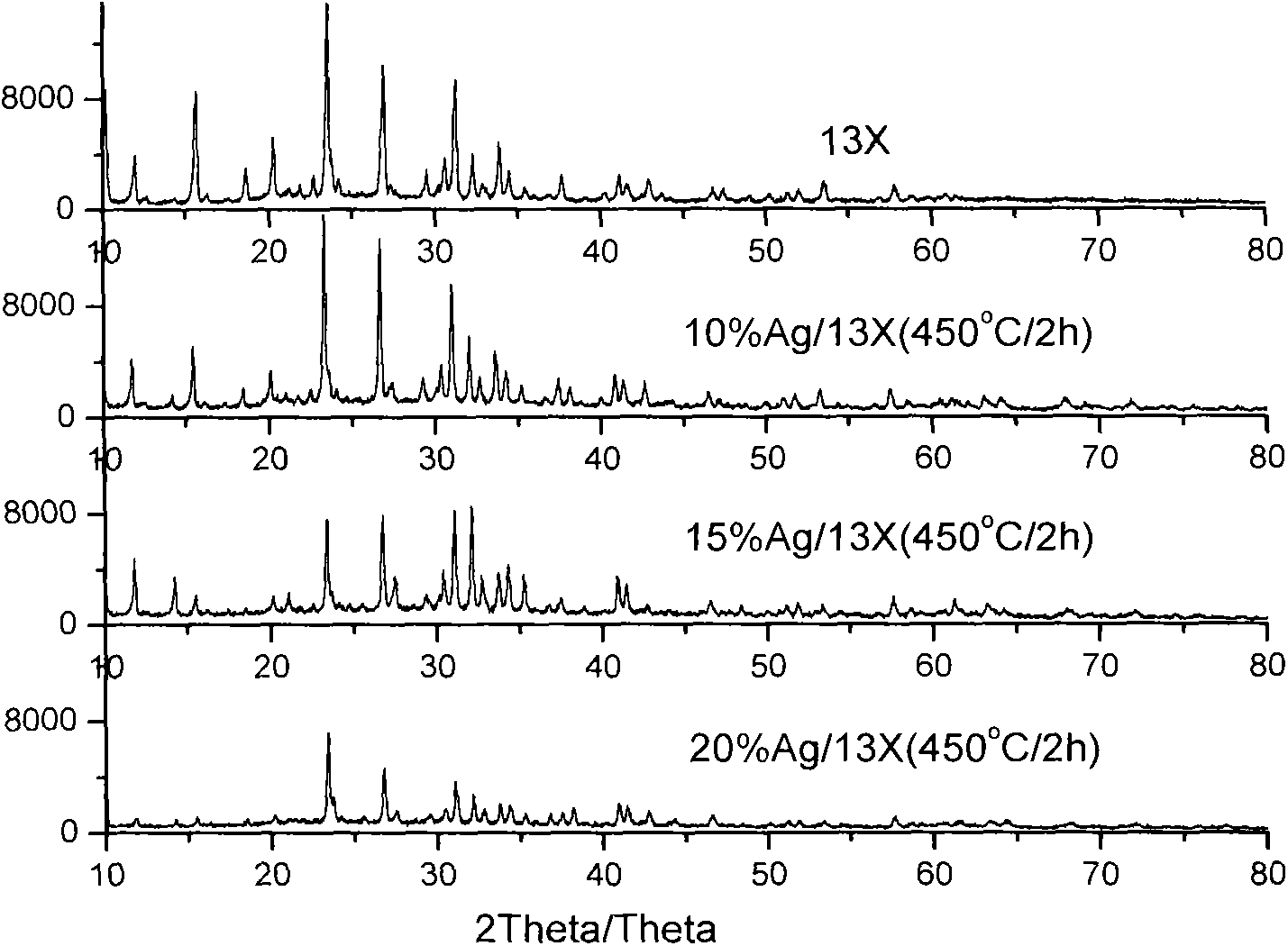

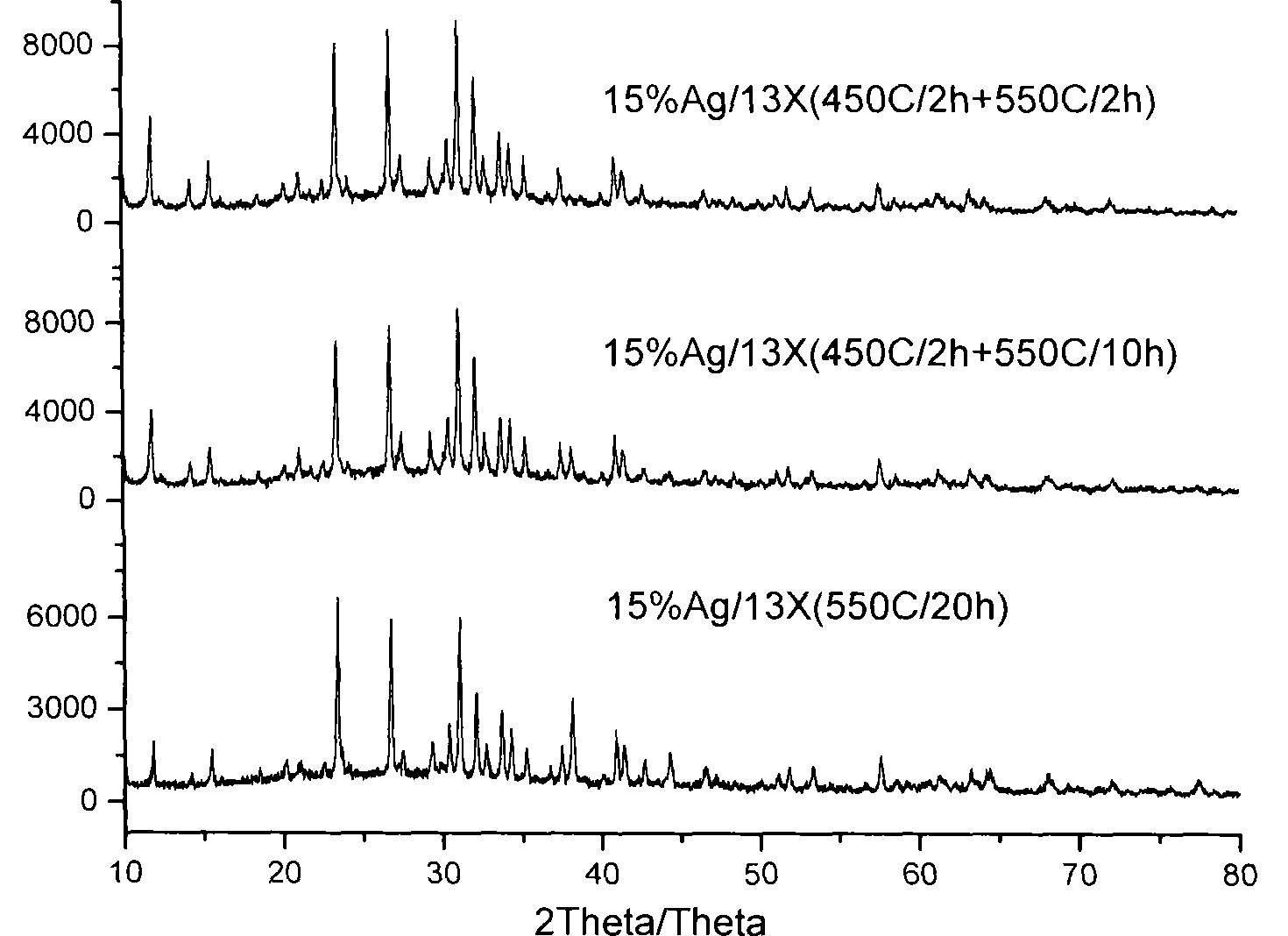

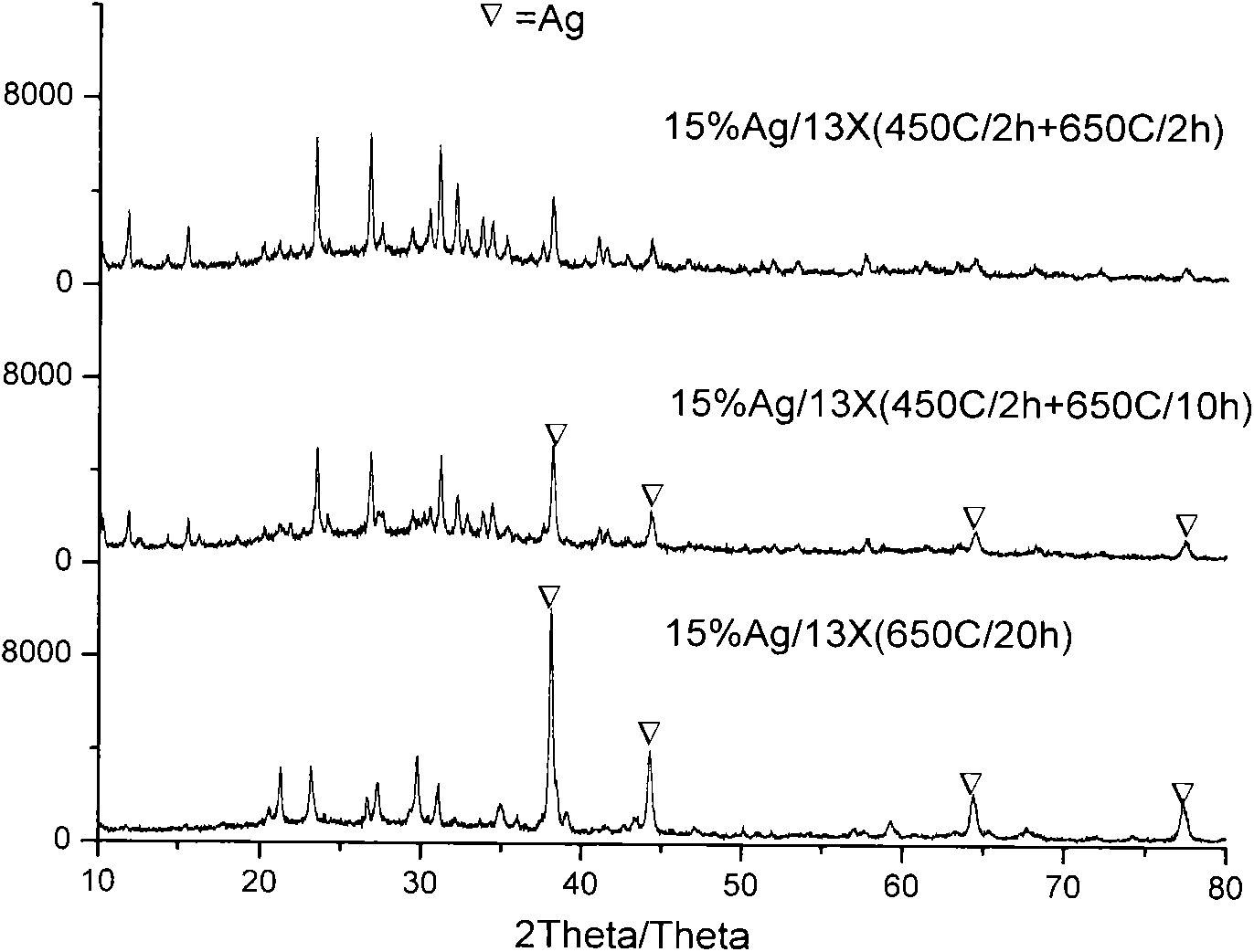

[0038] The crystal phase structure of the carrier 13X molecular sieve and the adsorbent 15%Ag / 13X (450C / 2h) is analyzed by XRD (X-ray diffraction), and the spectrogram is as follows figure 1 As shown, the results show that the sample 15%Ag / 13X (450C / 2h) maintains the crystal phase structure of 13X molecular sieve.

[0039] (2) Test of 15%Ag / 13X adsorption performanc...

Embodiment 2

[0042] Except that the bed temperature of the adsorption column is 550° C., the others are the same as in Example 1. The measured and calculated decontamination coefficient DF is shown in Table 1.

Embodiment 3

[0044] Except that the bed temperature of the adsorption column is 650° C., the others are the same as in Example 1. The measured and calculated decontamination coefficient DF is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com