Preparation method of wave absorbing member and wave absorbing member

A wave absorbing agent, first-class technology, applied in the direction of coating, etc., can solve the problems of non-continuous production and complicated process, and achieve the effect of shortening the unit time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

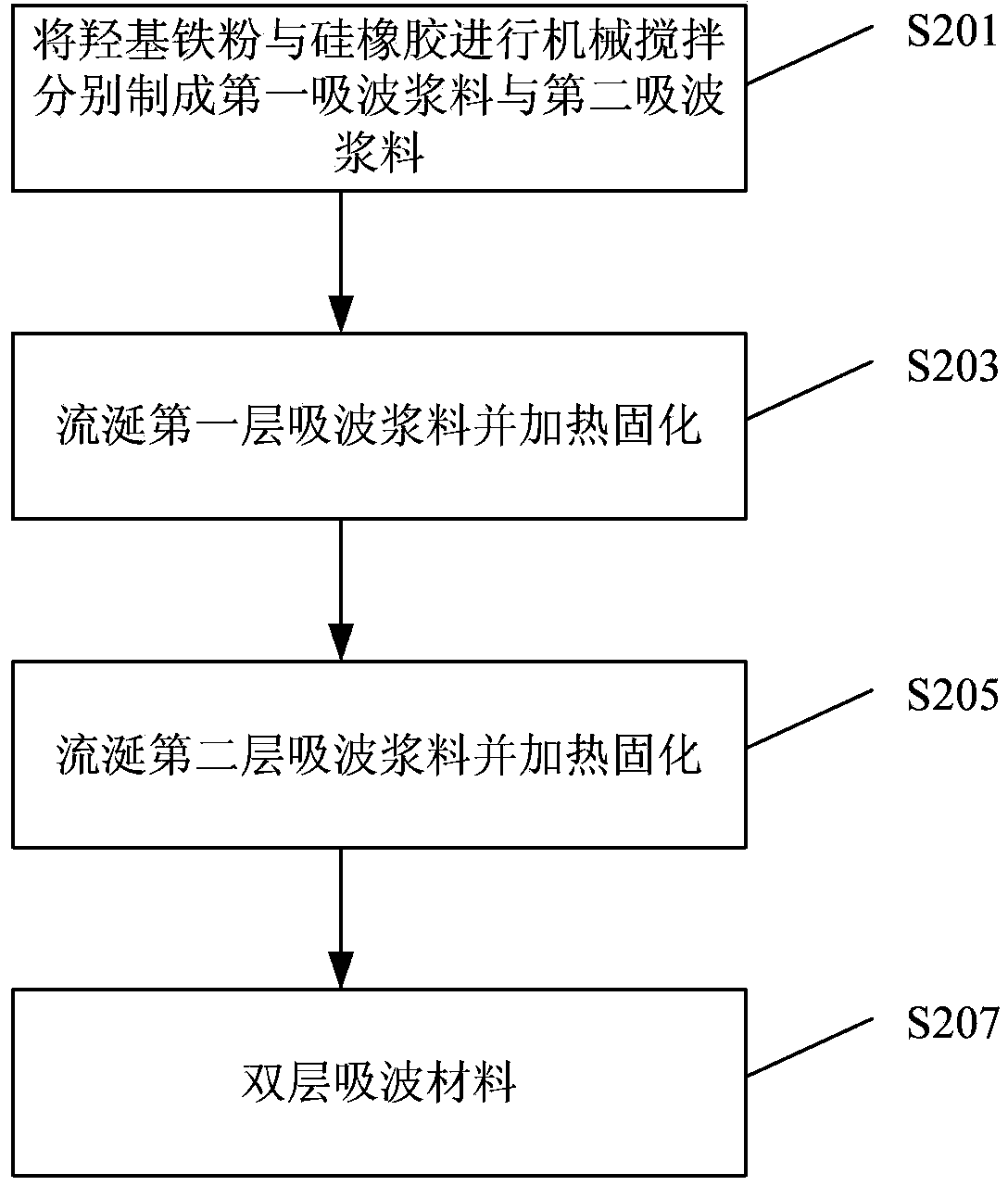

[0074] Such as figure 2 As shown, the specific process of using the technical solution of the present invention to carry out the salivation process to prepare the wave absorbing part includes:

[0075] Step S201, mechanically stirring the hydroxyl iron powder and the silicone rubber, the weight ratio of the hydroxyl iron powder and the silicone rubber is 13:7, and mixing them into a uniform wave-absorbing slurry as the first wave-absorbing slurry; mixing the hydroxyl iron powder and the silicone rubber Mechanical stirring, the weight ratio of hydroxyl iron powder and silicone rubber is 17:3, mixed into a uniform wave-absorbing slurry as the second wave-absorbing slurry, wherein the mixer used for mechanical stirring is a digital Display speed electronic mixer, mixing stirring time is 1h, stirring speed is 300r / min.

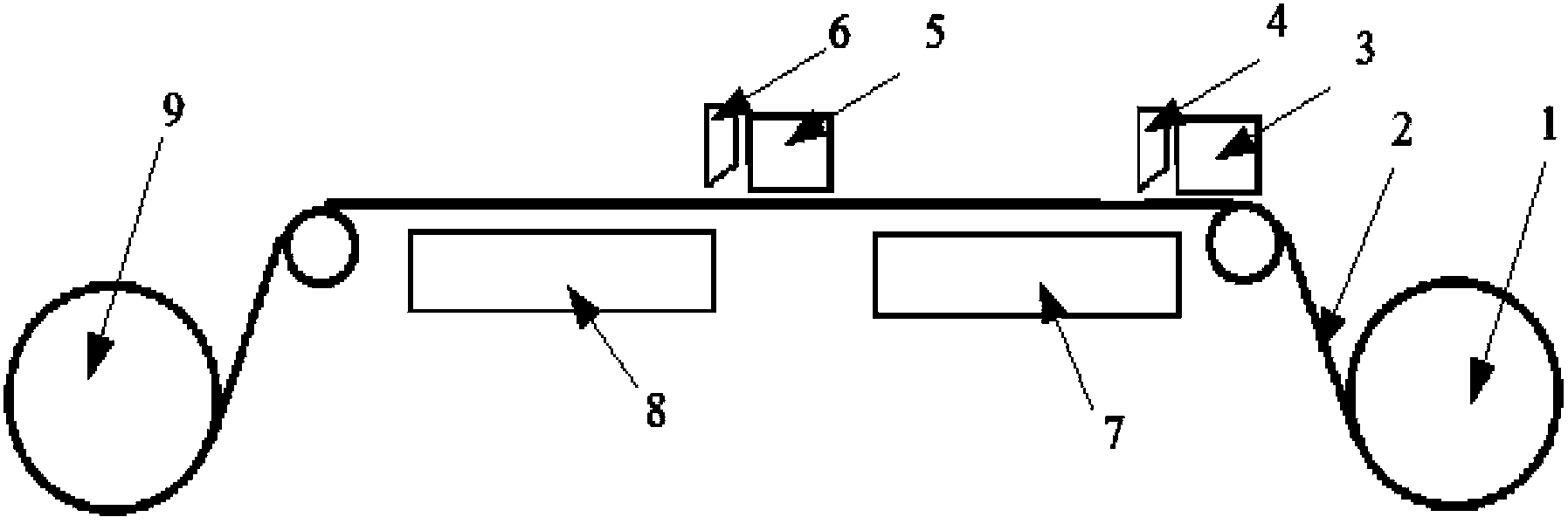

[0076] Step S203, add the absorbing slurry to the first trough 3 of the drooling machine, the gap between the first drool knife 4 and the conveyor belt 2 is 1 m...

Embodiment 2

[0080] Step S201, mechanically stirring the carbonyl iron powder and the silicone rubber, the weight ratio of the hydroxyl iron powder and the silicone rubber is 7:3, and mixing them into a uniform wave-absorbing slurry as the first wave-absorbing slurry; mixing the hydroxyl iron powder and the silicone rubber Mechanical stirring, the weight ratio of hydroxyl iron powder and silicone rubber is 4:1, mixed into a uniform wave-absorbing slurry as the second wave-absorbing slurry, wherein the mixer used for mechanical stirring is a digital Display speed electronic mixer, mixing stirring time is 1h, stirring speed is 300r / min.

[0081] Step S203, stirring the first wave-absorbing slurry for 5 minutes. Then add the wave-absorbing slurry to the first trough 3 of the drooling machine to drool, the gap between the first drool knife 4 and the conveyor belt 2 is 1 mm, and the first slobber knife 4 scrapes the first wave-absorbing slurry on the conveyor belt 2 Flat, forming the first sal...

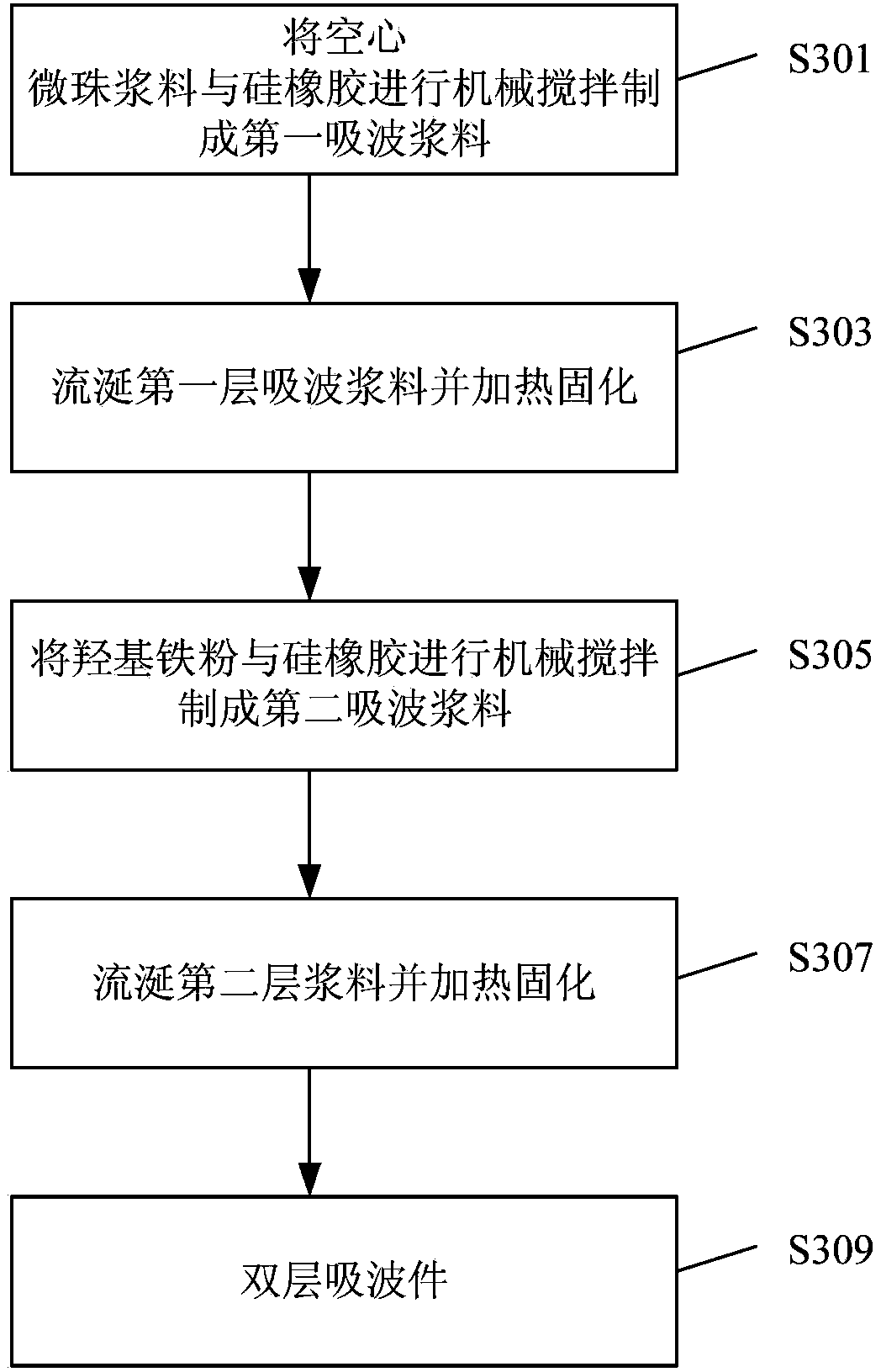

Embodiment 3

[0085] Step S201, mechanically stirring the hydroxyl iron powder and the room temperature curing silicone rubber, the weight ratio of the hydroxyl iron powder and the room temperature silicone rubber is 3:1, and mixing them into a uniform wave-absorbing slurry as the first wave-absorbing slurry; the hydroxyl iron powder and the The silicone rubber is mechanically stirred, and the weight ratio of hydroxyl iron powder to silicone rubber is 4:1, and mixed into a uniform wave-absorbing slurry as the second wave-absorbing slurry. The mixer used for mechanical stirring is Shanghai Suoying Instrument Equipment Co., Ltd. The digital display speed of production is an electronic mixer, the mixing time is 1h, and the stirring speed is 300r / min.

[0086] Step S203, stirring the first wave-absorbing slurry for 5 minutes. Then add the wave-absorbing slurry to the first trough 3 of the drooling machine to drool, the gap between the first drool knife 4 and the conveyor belt 2 is 1 mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com