A potassium chloride particle fertilizer and a preparing method thereof

A technology of granular fertilizer and potassium chloride, applied in the directions of potassium fertilizer, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of high cost of potassium chloride granular fertilizer, long dissolving time of particles, long production cycle, etc. The effect of short dissolution time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention embodies a preparation method of potassium chloride granular fertilizer, which can be used to prepare the above-mentioned potassium chloride granular fertilizer, and can also be used for the preparation of other unmentioned potassium chloride granular fertilizers. The method Include the following steps:

[0029] S01. Mix the bonding material, quick-setting agent, wetting agent and water according to the ratio of 51-2:1-2:18-22.5:73.5-80 by weight, and prepare potassium chloride granulation forming aid;

[0030] S02. The auxiliary granulation material, potassium chloride powder and the potassium chloride granulation forming aid are mixed according to the weight ratio of 2-3:95-97:1-2, and then granulated sequentially, Dry and sieve to obtain potassium chloride granules.

[0031] Specifically, in the above step S01, the bonding material, quick-setting agent, wetting agent and water are mixed, and the mixing method is not limited. In the embodiment o...

Embodiment 1

[0037] A kind of potassium chloride granular fertilizer and preparation method thereof

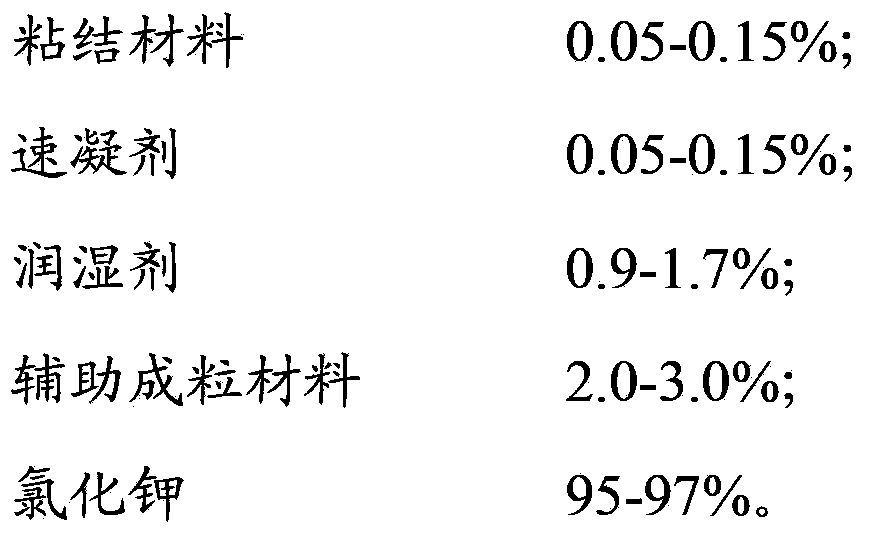

[0038] The potassium chloride granule fertilizer is based on its gross weight as 100%, and the potassium chloride granule fertilizer comprises the composition of following percentage by weight:

[0039]

[0040] The preparation method of above-mentioned potassium chloride granular fertilizer:

[0041] Mix the above-mentioned binding material, quick-setting agent, wetting agent and water respectively according to the weight ratio to prepare potassium chloride granulation forming aid;

[0042] The auxiliary granulation material, potassium chloride powder and the potassium chloride granulation forming aid are mixed and then granulated, dried and sieved to obtain potassium chloride granules, wherein the granulation temperature is 60 °C, the drying temperature is 270 °C. The prepared potassium chloride granule fertilizer has a particle diameter of 2.0-4.75mm, a smooth and round surface, an...

Embodiment 2

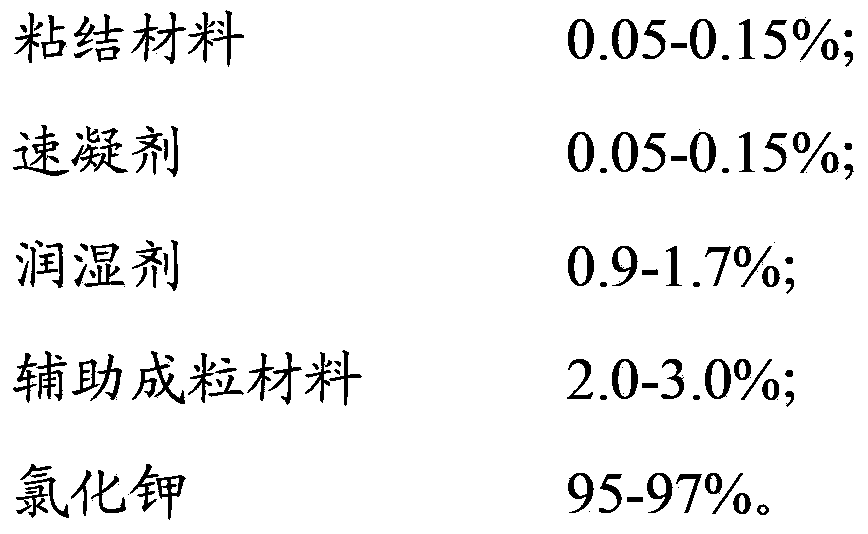

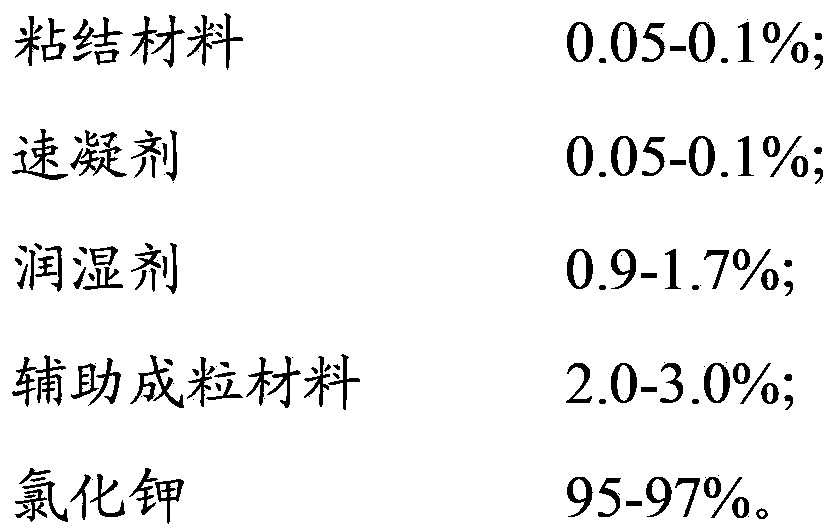

[0044] A kind of potassium chloride granular fertilizer and preparation method thereof

[0045] The potassium chloride granule fertilizer is based on its gross weight as 100%, and the potassium chloride granule fertilizer comprises the composition of following percentage by weight:

[0046]

[0047] The preparation method of above-mentioned potassium chloride granular fertilizer:

[0048] Mix the above-mentioned binding material, quick-setting agent, wetting agent and water respectively according to the weight ratio to prepare potassium chloride granulation forming aid;

[0049] The auxiliary granulation material, potassium chloride powder and the potassium chloride granulation forming aid are mixed and then granulated, dried and sieved to obtain potassium chloride granules, wherein the granulation temperature is 65 °C, the drying temperature is 290 °C. The prepared potassium chloride granule fertilizer has a particle diameter of 2.0-4.75mm, a smooth and round surface, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com