Aqueous resin used of floor polishing agent

A polishing agent, water-based technology, applied in polishing compositions, chemical instruments and methods, etc., can solve the problem of not fully meeting the high requirements of those who need it, and achieve the effects of excellent peelability, efficient maintenance of business, and protection of aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

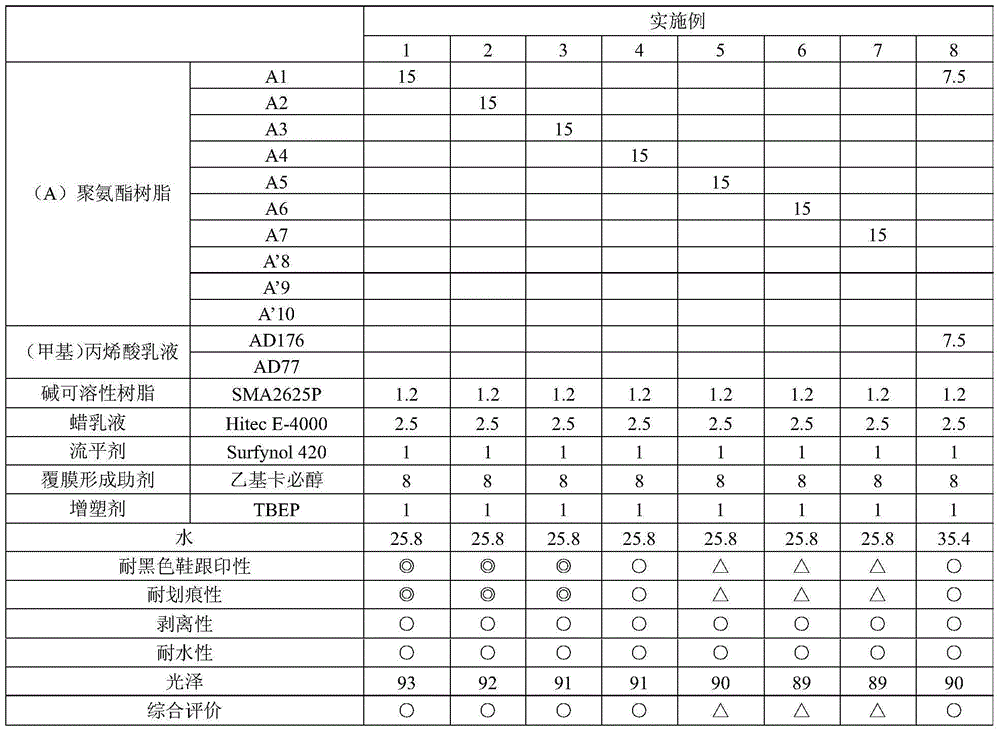

Examples

Embodiment

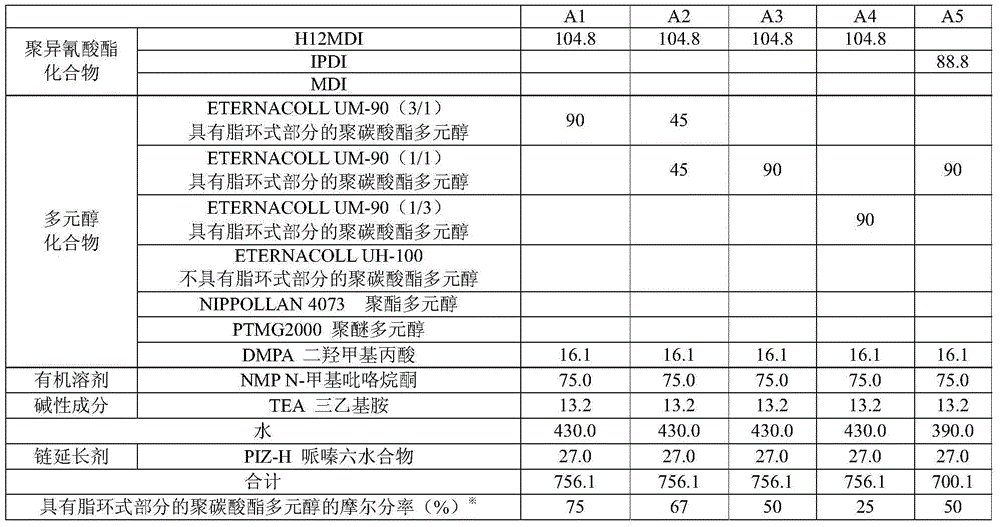

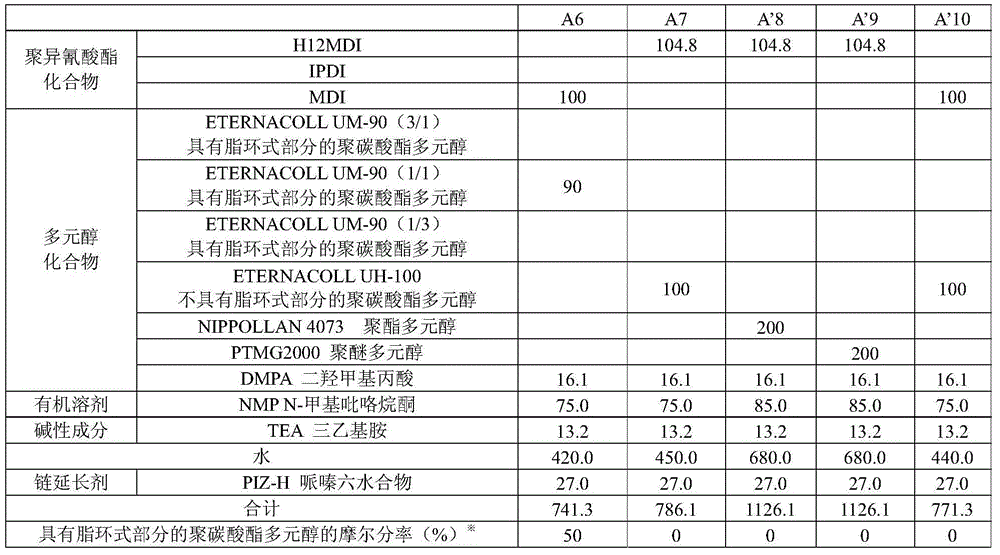

[0117] Hereinafter, the present invention will be described specifically and in detail by examples and comparative examples, but these examples are only one embodiment of the present invention, and the present invention is not limited by these examples. In this embodiment, parts refer to parts by weight. (A) The components used for manufacture of an aqueous polyurethane resin are as follows.

[0118]

[0119] Cycloaliphatic Polyisocyanate

[0120] H12MDI: Hydrogenated diphenylmethane diisocyanate, brand name: Desmodur W, manufactured by Sumika Bayer Urethane Co., Ltd.

[0121] IPDI: Isophorone diisocyanate, trade name: Desmodur I, manufactured by Sumika Bayer Urethane Co., Ltd.

[0122] Aromatic isocyanate

[0123] MDI: diphenylmethane diisocyanate, trade name: Millionate MT, manufactured by Nippon Polyurethane Industry Co., Ltd.

[0124]

[0125] Polycarbonate polyols with alicyclic moieties

[0126] ETERNACOLL UM-90(3 / 1): The number average molecular weight obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com