Photoluminescent coating material and preparation method thereof

A technology of photoluminescent paint and photoluminescent material, applied in the direction of luminescent paint and coating, can solve the problems of unstable performance and low strength, and achieve the effect of good gloss performance, improved coverage performance and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention also provides a preparation method of the photoluminescent coating, the method comprising the steps of:

[0052] S1. Put natural muscovite powder into a mixer, then add dispersant, film-forming aid, thickener and defoamer in sequence, and mix to obtain the first mixture;

[0053] S2. Add a photoluminescent material to the first mixture obtained in step S1 and mix to obtain a second mixture;

[0054] S3. Add polymer emulsion and deionized water to the second mixture to disperse evenly to obtain a photoluminescent coating.

[0055] In the preparation method of the photoluminescent paint provided by the present invention, the photoluminescent material can be photoluminescent paint of various colors. Red photoluminescent materials, green photoluminescent materials and blue photoluminescent materials are preferred in the present invention.

[0056] Preferably, the preparation method of the red photoluminescent material is: Al 2 o 3 , MS, M'CO 3 、Eu...

Embodiment 1

[0071] 1. Preparation of red luminescent materials,

[0072] Raw material: Al 2 o 3 204g, MgS84g, CaCO 3 175 grams, Eu 2 o 3 1.76 g, La 2 o 3 3.26 grams.

[0073] The above raw materials are mixed and ground to make the particle size of the mixed powder less than 10 μm, and the microwave frequency is selected as 150 GHz. The above raw materials are fully mixed with a high-speed dispersing mixer, put into a crucible, placed in a microwave oven, heated for 40 minutes, taken out and cooled to obtain a red photoluminescent material.

[0074] 2. Preparation of photoluminescent coating:

[0075] Raw materials: 150 grams of photoluminescent material obtained in step 1, 20 grams of natural muscovite powder, 20 grams of dispersant, 20 grams of film-forming aid, 15 grams of thickener, 5 grams of defoamer, 150 grams of polymer emulsion, 620 grams of deionized water.

[0076] First put the natural muscovite powder into the mixer, then add the raw material dispersant, film-formin...

Embodiment 2-14

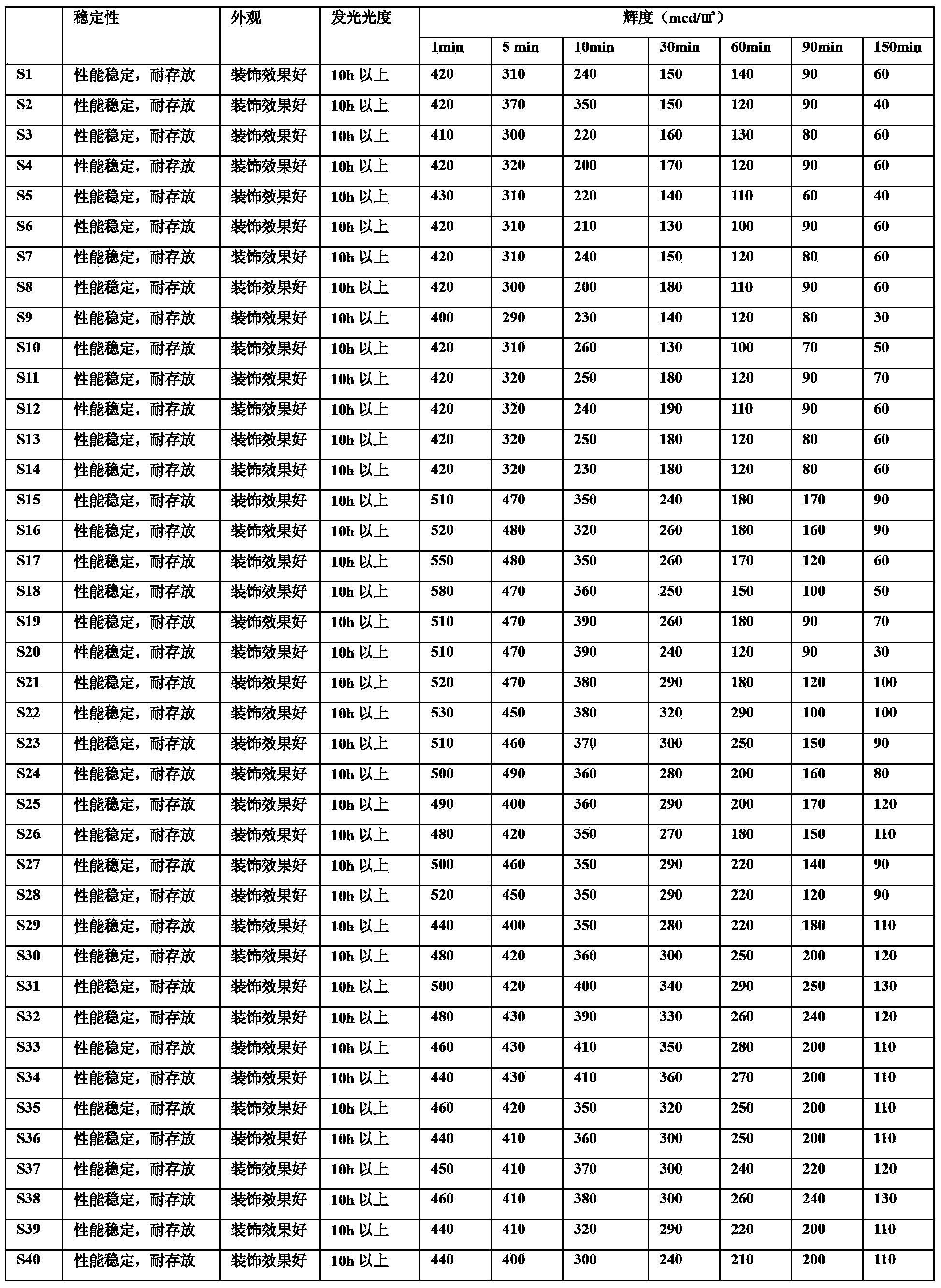

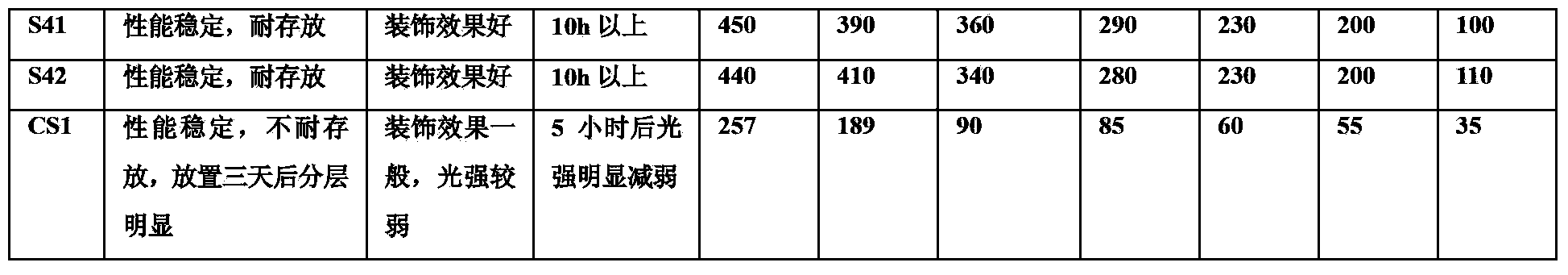

[0078] Photoluminescent coatings A2-A14 were prepared according to the method of Example 1, the difference being that the raw materials for preparing photoluminescent materials are shown in Table 1.

[0079] Table 1

[0080]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com