Expandable self-generated gas foam gel and preparation method and application thereof

A technology of expanding foam and self-gassing, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of high application cost, and achieve the effects of simple construction, good volume expansion and stability, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

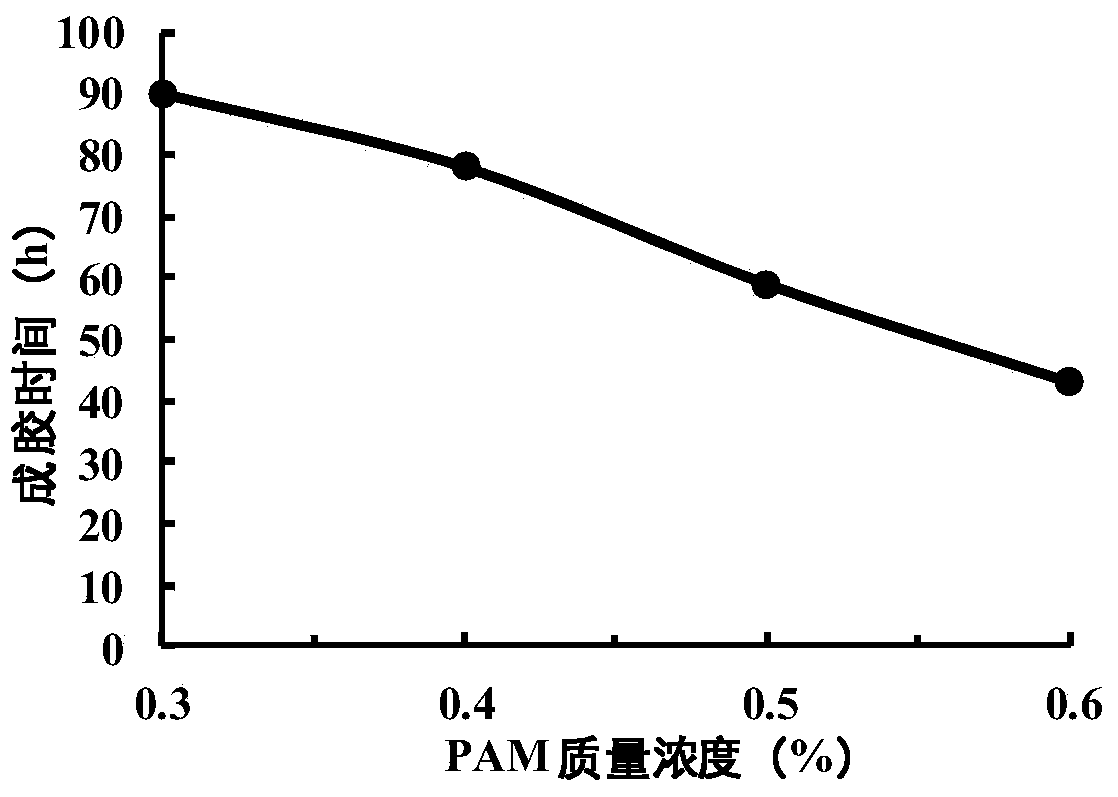

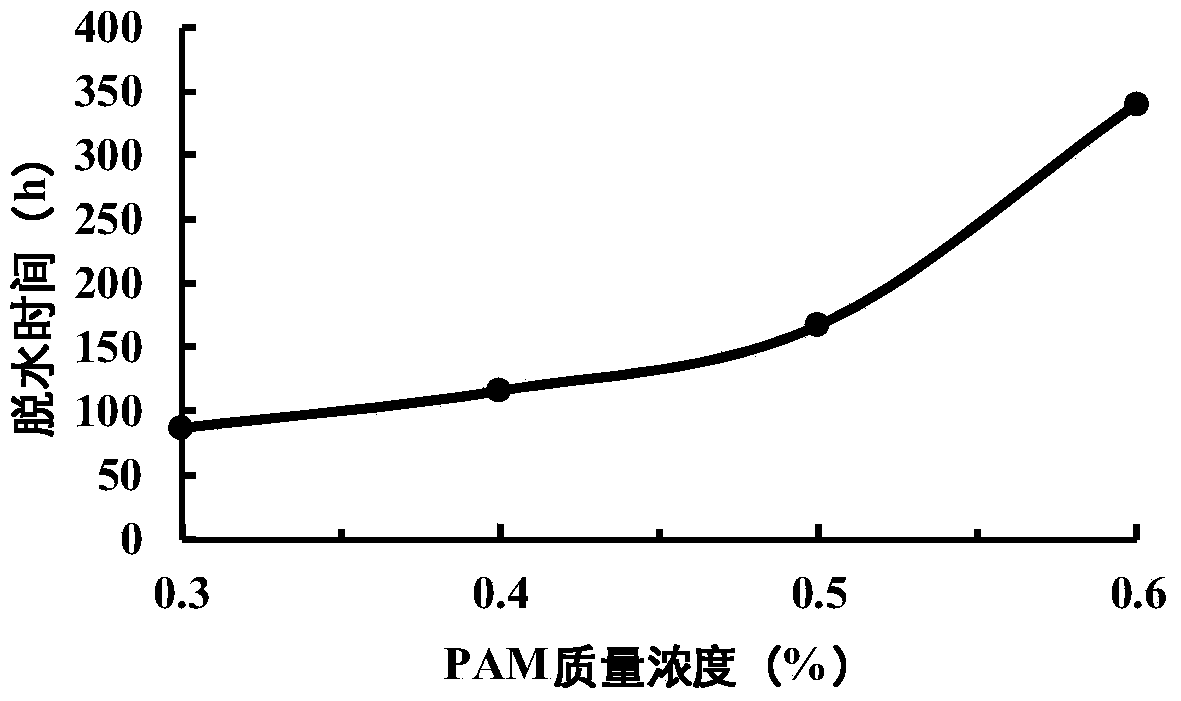

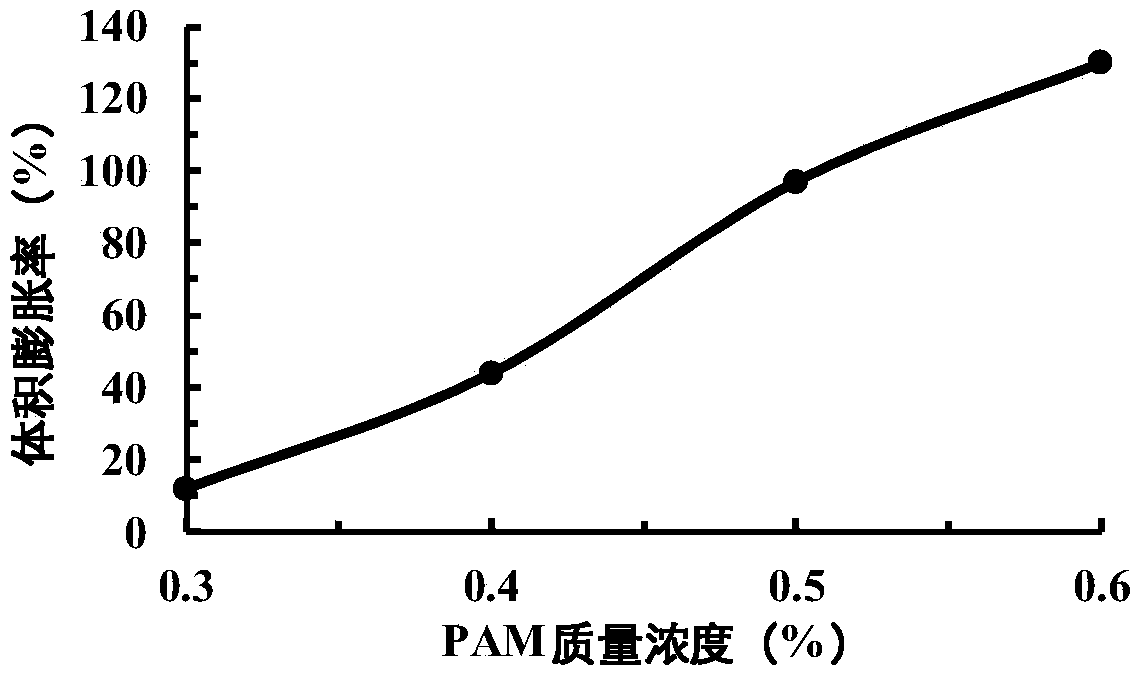

[0052] Main drug: polyacrylamide, with a relative molecular mass of 18 million and a degree of hydrolysis of 23%; Na 2 SO 3 , analytically pure; Na 2 Cr 2 o 7 , analytically pure; dilute hydrochloric acid, mass fraction 15%, analytically pure; NH 4 Cl, analytically pure; NaNO 2 , analytically pure. Embodiment 1: prepare the self-gas expandable foam jelly of different PAM concentrations

[0053] Prepare 4 groups of self-gasifying expandable foam jelly solutions, the PAM concentrations are 0.3%, 0.4%, 0.5%, 0.6%, and the cross-linking agent is 0.5% Na 2 Cr 2 o 7 +0.6%Na 2 SO 3 , the heat generating agent is 1mol / L NH 4 Cl+1mol / L NaNO 2 , the pH value is 6.8, and the preparation method is as follows:

[0054] (1) Weigh 0.3g, 0.4g, 0.5g, 0.6g of PAM respectively, add them into 4 groups of beakers filled with 100g of distilled water, stir until uniform; add 0.5g of Na to each group 2 Cr 2 o 7 and 0.6gNa 2 SO 3 , stir until uniform;

[0055] (2) Weigh 4 groups of ...

Embodiment 2

[0067] Embodiment 2: Preparation of self-gas expandable foam jelly with different crosslinking agent concentrations

[0068] Prepare 4 groups of self-generated expandable foam jelly liquid, crosslinking agent (chromium jelly Cr 2 (SO 4 ) 3 Reaction formula such as Ⅰ, mass ratio Na 2 Cr 2 o 7 : Na 2 SO 3 : Cr 2 (SO 4 ) 3 0.5:0.6:0.6) concentrations are 0.15%, 0.3%, 0.6%, 0.9%, PAM concentration is 0.6%, heat generating agent is 1mol / LNH 4 Cl+1mol / LNaNO 2 , the pH value is 6.8, and the preparation method is as follows:

[0069] Cr 2 o 7 2- +3SO 3 2- +8H + →Cr 2 (SO 4 ) 3 +4H 2 o

[0070] I

[0071] (1) Weigh 4 groups of PAM, each group of PAM is 0.6g, respectively add it into 4 groups of beakers filled with 100g distilled water, stir until uniform; weigh 4 groups of Na 2 Cr 2 o 7 、Na 2 SO 3 , respectively added to the above-mentioned 4 groups of PAM solutions, and stirred until uniform, the concentrations of the cross-linking agents in the 4 groups of...

Embodiment 3

[0079] Embodiment 3: Preparation of self-gas expandable foam jelly with different heat generating agent concentrations

[0080] Prepare 4 groups of self-generating expandable foam jelly solutions, the concentrations of heat generating agents are 0.5mol / L, 1mol / L, 1.5mol / L, and 2mol / L, the concentration of PAM is 0.6%, and the concentration of crosslinking agent is 0.5% Na 2 Cr 2 o 7 +0.6%Na 2 SO 3 , the pH value is 6.8, and the preparation method is as follows:

[0081] (1) Weigh 4 groups of PAM, each group of PAM is 0.6g, respectively add it into 4 groups of beakers containing 100g of distilled water, stir until uniform; add 0.5gNa 2 Cr 2 o 7 and 0.6gNa 2 SO 3 , stir until uniform;

[0082] (2) Weigh 4 groups of NH in proportion 4 Cl, NaNO 2 , respectively added in the 4 groups of solutions in step (1), and stirred evenly, the concentrations of heat generating agents in the 4 groups of solutions were respectively 0.5mol / L, 1mol / L, 1.5mol / L, and 2mol / L;

[0083] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volumetric expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com