touch screen

A touch screen and conductive layer technology, which is applied in lamination devices, instruments, electrical digital data processing, etc., can solve the problems of complicated production process, waste, and increased production cost, and achieve simple production process, low production cost and lower price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation of the above-mentioned UV-type photosensitive nano-conductive material is relatively simple, just mix the conductive agent, photosensitive material, photosensitive material and solvent according to a suitable ratio, and is convenient to use.

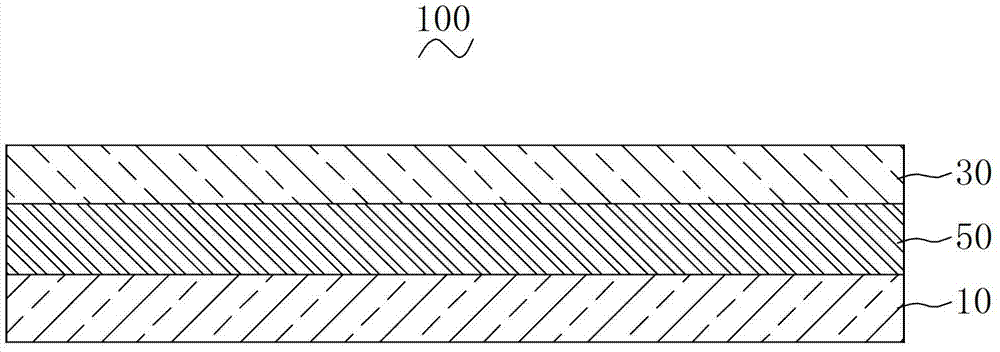

[0047] Preferably, the thickness of the first conductive electrode 32 is 0.01 micron to 15 micron, so that the light transmission of the first conductive layer is better.

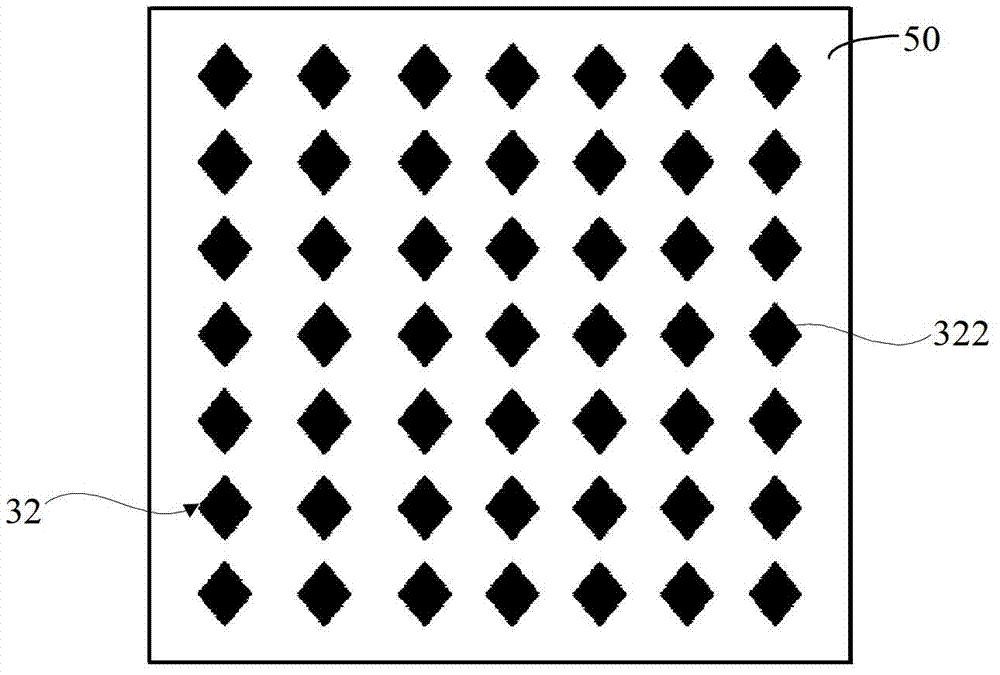

[0048] The first conductive electrode 32 includes a plurality of diamond-shaped conductive patterns 322 distributed in rows and columns. It can be understood that, in other implementation manners, the conductive pattern 322 may be in other shapes, such as square, rectangle, etc., or other irregular shapes.

[0049] A plurality of first conductive bridges are disposed on the first conductive electrode 32 , and each first conductive bridge connects the two connected conductive patterns 322 to conduct the two connected conductive patterns 322 .

...

Embodiment 1

[0067] Prepare touch screen

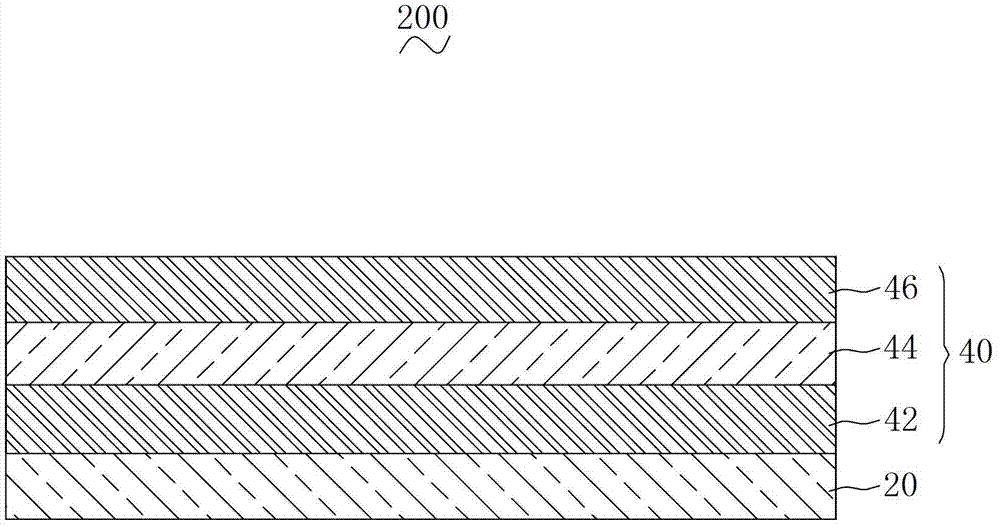

[0068] (1) Coating UV-type photosensitive nano-conductive material on one surface of the glass panel to form a UV-type photosensitive nano-conductive material layer with uniform thickness; on the UV-type photosensitive nano-conductive material layer covered with the required first conductive pattern nested mask plate, and then exposed, and then soak the exposed UV-type photosensitive nano-conductive material layer in an aqueous solution of sodium carbonate for development, after development and curing, the first conductive electrode is formed on the surface of the glass panel, Obtain a semi-finished product; wherein, the UV-type photosensitive nano-conductive material includes 0.6% of conductive agent, 10% of photosensitive material, 0.1% of photosensitive material and 89.3% of solvent in terms of mass percentage;

[0069] (2) Put the above semi-finished product into the automatic brushing machine, print photosensitive silver paste on the first co...

Embodiment 2

[0071] Prepare touch screen

[0072] (1) Coating UV-type photosensitive nano-conductive material on one surface of the glass panel to form a UV-type photosensitive nano-conductive material layer with uniform thickness; The nested mask plate is then exposed, and then the exposed UV-type photosensitive nano-conductive material layer is soaked in an aqueous solution of sodium bicarbonate for development, and after development and curing, the first conductive electrode is formed on the surface of the glass panel. Obtain a semi-finished product; wherein the UV-type photosensitive nano-conductive material includes 0.2% conductive agent, 15% photosensitive material, 0.8% photosensitive material and 84% solvent in terms of mass percentage;

[0073] (2) Put the above semi-finished product into the automatic brushing machine, print photosensitive silver paste on the first conductive electrode, put it into the infrared baking oven for pre-baking, and then put it into the exposure machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com