United degradation method for dehydrated crude in water by petroleum degradation bacterial flora and surfactant

A technology of surfactants and petroleum degrading bacteria, which is applied in the field of environmental biology, can solve the problems of poisonous microorganisms, low degradation efficiency, and the impact of microbial toxicity, and achieve the effect of simple method and accelerated degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

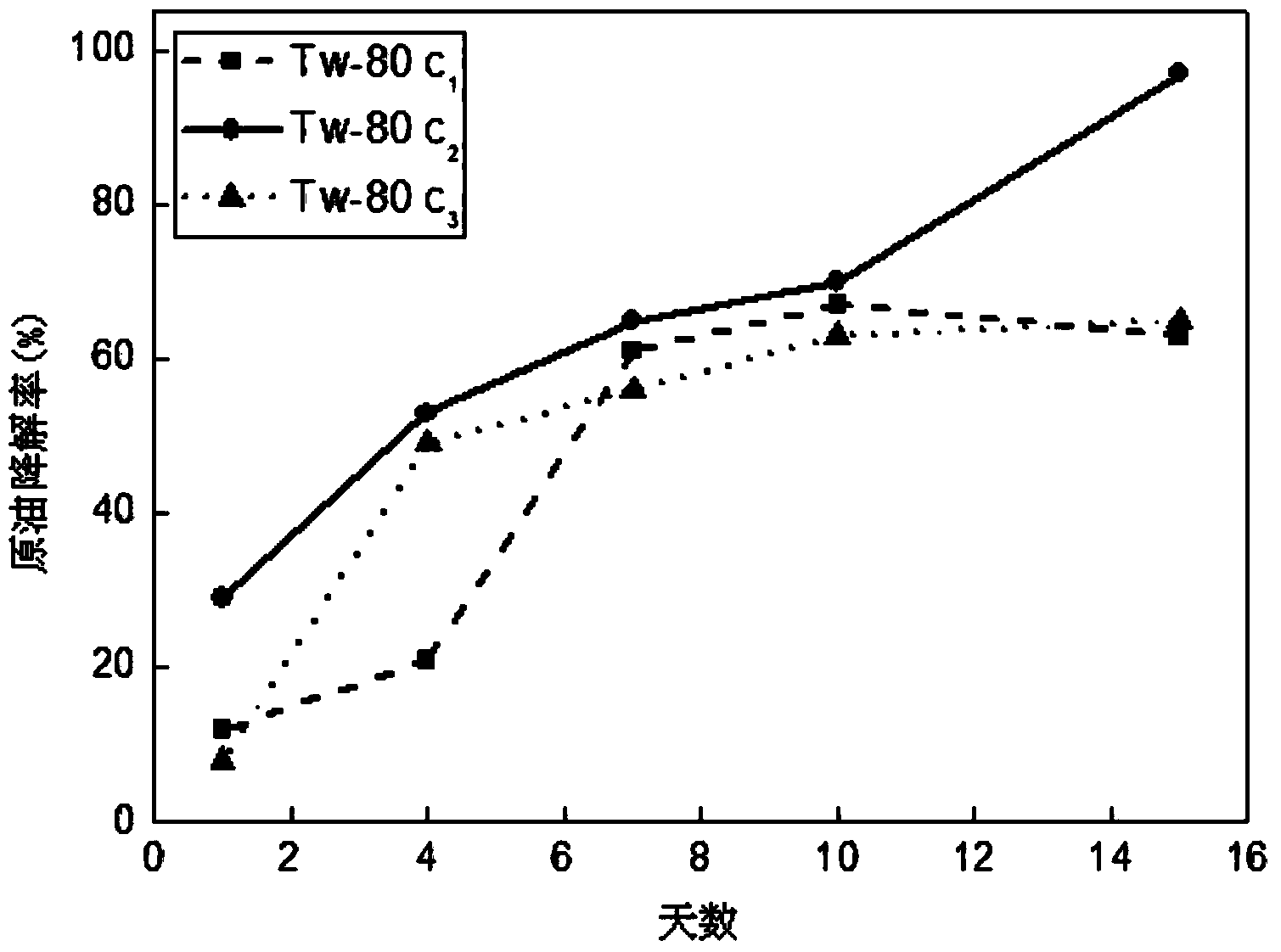

Embodiment 1

[0030] This example uses petroleum hydrocarbon degrading bacteria group and surfactant Tw-80 (c 1 Concentration, c 2 Concentration, c 3 concentration) to jointly degrade dehydrated crude oil, the specific steps are as follows:

[0031] Step (1), enrichment of petroleum hydrocarbon degrading bacteria:

[0032] a: Weigh 1g of petroleum-contaminated soil sample and put it into a 1L Erlenmeyer flask with petroleum hydrocarbon-degrading bacteria culture medium;

[0033] b: The formula of the above-mentioned petroleum hydrocarbon degrading bacteria culture medium is as follows: 65mg K 2 HPO 4 , 25.5mg KH 2 PO 4 , 133.8mg Na 2 HPO 4 12H 2 O, 500mg NH 4 Cl, 82.5mg CaCl 2 , 67.5mg MgSO 4 ·7H 2 O, 0.75mgFeCl 3 ·6H 2 O. Mix with 1000mL deionized water to adjust the pH value to 7.0. Take 100mL of the above-prepared solution and add it to a 1L Erlenmeyer flask, and sterilize at 120°C for 20min. There is the triangular flask of petroleum hydrocarbon degrading bacteria cultur...

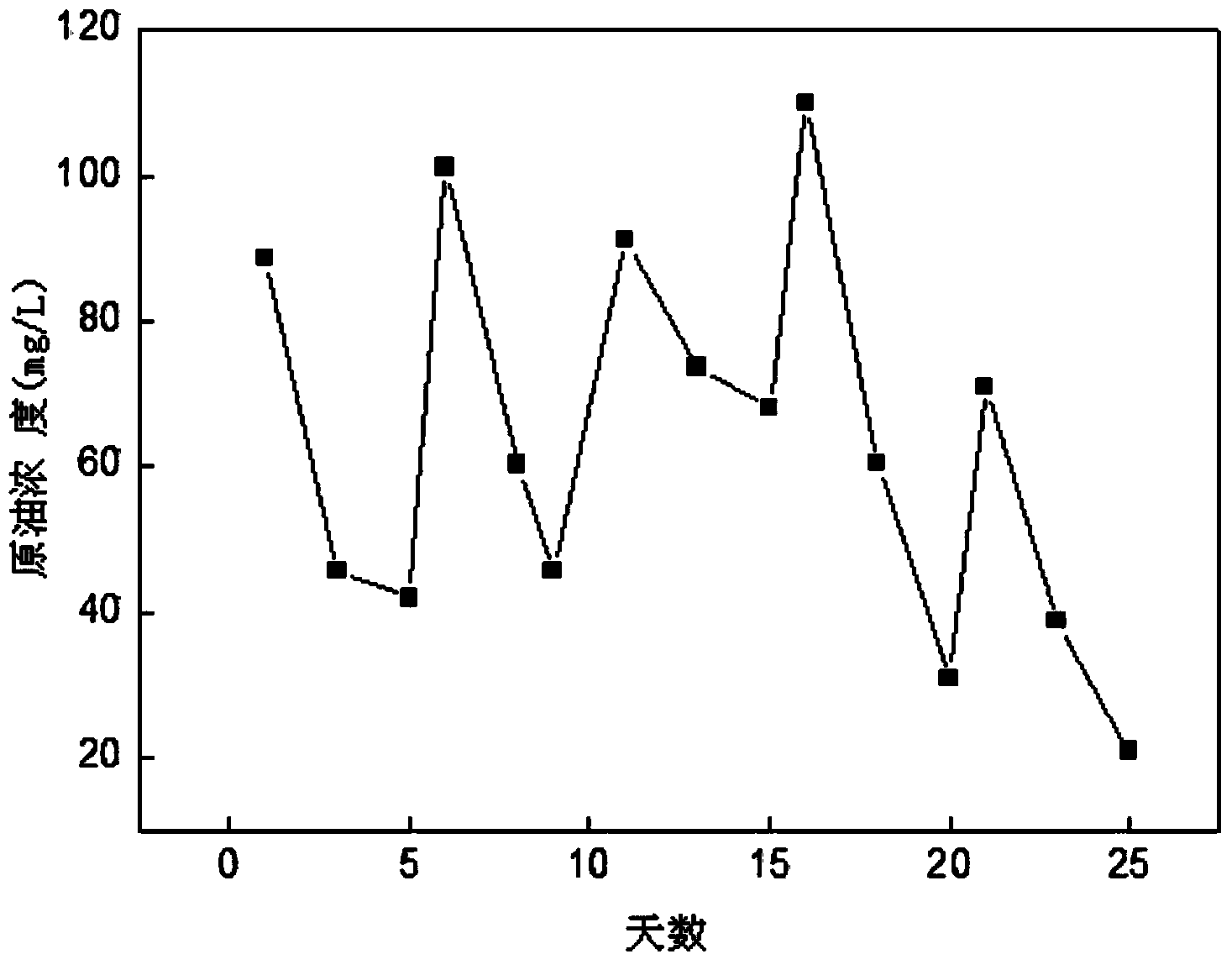

Embodiment 2

[0046] In this example, petroleum hydrocarbon degrading bacteria were combined with surfactants Tw-80, SDS, and LAS to degrade dehydrated crude oil. The specific steps are as follows:

[0047] Step (1), enrichment of petroleum hydrocarbon degrading bacteria:

[0048] Step (1) is identical with example 1;

[0049] Step (2), adding different surfactants to combine with petroleum hydrocarbon degrading bacteria to degrade dehydrated crude oil:

[0050] Get 10mL of the culture fluid petroleum hydrocarbon-degrading bacteria culture medium prepared in the above-mentioned step (1) b, and 1mL of the petroleum-hydrocarbon-degrading bacterial colony obtained in the above-mentioned step (1) e, put into a 50mL conical flask; Add 0.01g of dehydrated crude oil to the bottle; then add surfactant Tw-80, SDS, LAS1mL; place in a constant temperature shaking box, keep the temperature at 30°C, and cultivate at a speed of 180r / min to degrade the crude oil in it.

[0051] Erlenmeyer flask is set a...

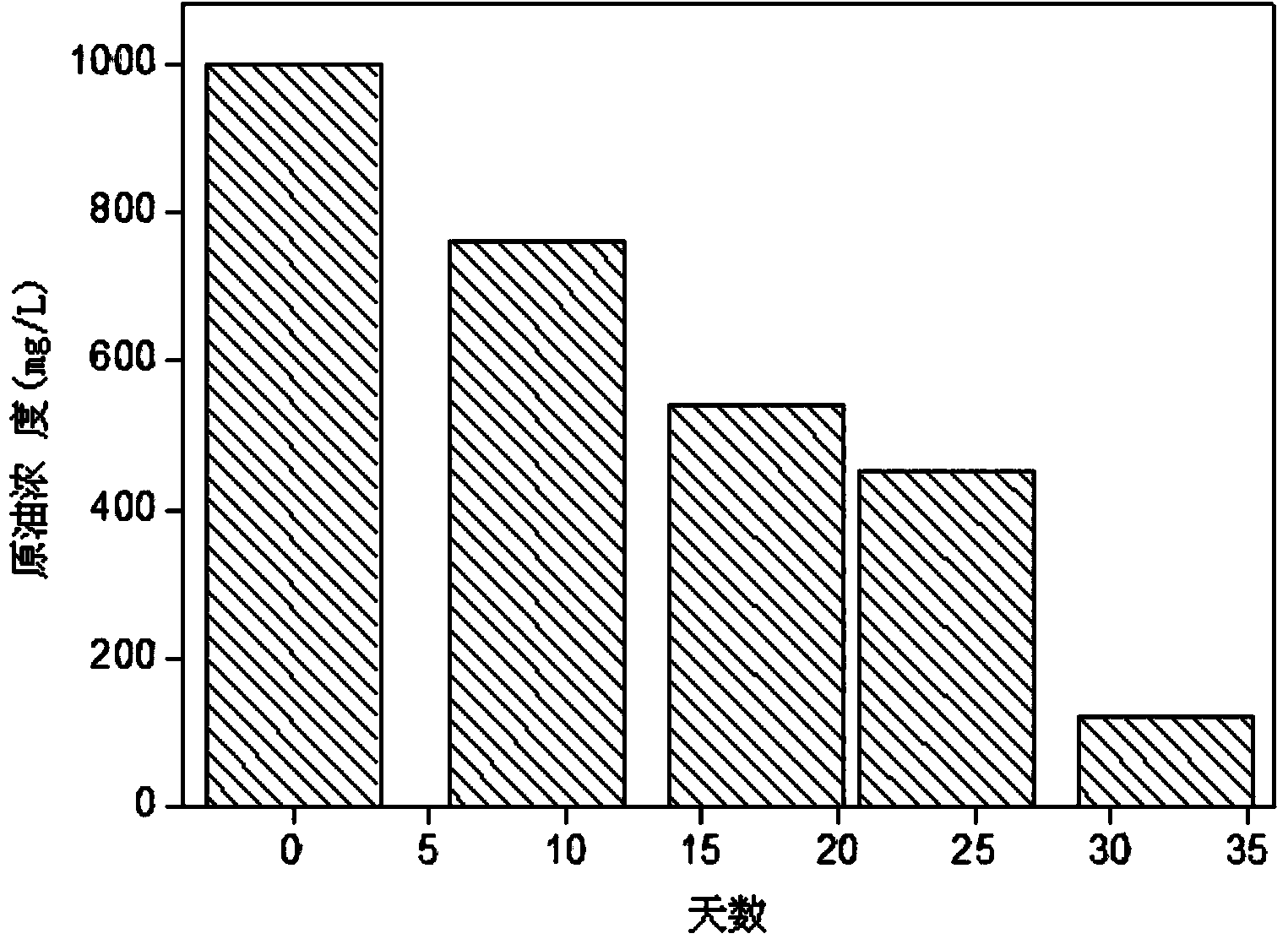

Embodiment 3

[0058] In this example, oil-degrading bacteria were combined with mixed surfactants (Tw-80+SDS, Tw-80+LAS) to degrade dehydrated crude oil. The specific steps are as follows:

[0059] Step (1), enrichment of petroleum hydrocarbon degrading bacteria:

[0060] Step (1) is identical with example 1;

[0061] Step (2), adding different surfactants to combine with petroleum hydrocarbon degrading bacteria to degrade dehydrated crude oil:

[0062] Get 10mL of the culture fluid petroleum hydrocarbon-degrading bacteria culture medium prepared in the above-mentioned step (1) b, and 1mL of the petroleum-hydrocarbon-degrading bacterial colony obtained in the above-mentioned step (1) e, put into a 50mL conical flask; Add 0.01g of dehydrated crude oil to the bottle; add 1mL of surfactants (Tw-80+SDS, Tw-80+LAS); place in a constant temperature shaking box, keep the temperature at 30°C, and cultivate at a speed of 180r / min. to degrade the crude oil in it.

[0063] Erlenmeyer flask is set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com