Coal mine wastewater pretreatment device

A pretreatment device and coal mine wastewater technology, which is applied in mining wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of increased damage to hydraulic components, increased investment in equipment maintenance parts, and poor water quality. Small area, low production cost, good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

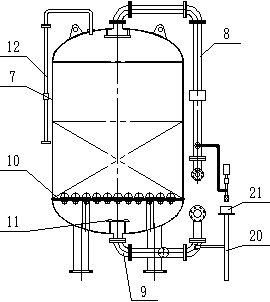

[0014] Such as figure 1 As shown, the coal mine wastewater pretreatment device includes a first tank body 7, a first water inlet pipe 8, a first water outlet pipe 9 and a perforated plate 10, the top of the tank body 7 is provided with a water inlet pipe 8, and the bottom is provided with an outlet pipe 9 , the interior of which is provided with a filter material layer 12 and a porous plate 10, the filter material layer is arranged above the porous plate 10, the outlet pipe 9 extends to the inside of the tank body 7, and the top of the outlet pipe 9 is covered with an anti-shock plate 11, the top of the tank body 7 is also provided with an exhaust pipe 12;

[0015] The porous plate 10 is provided with a water cap.

[0016] A sampling pipe 20 is provided on the outlet pipe 9 , and a sampling tank 21 is provided at the bottom of the sampling pipe 20 .

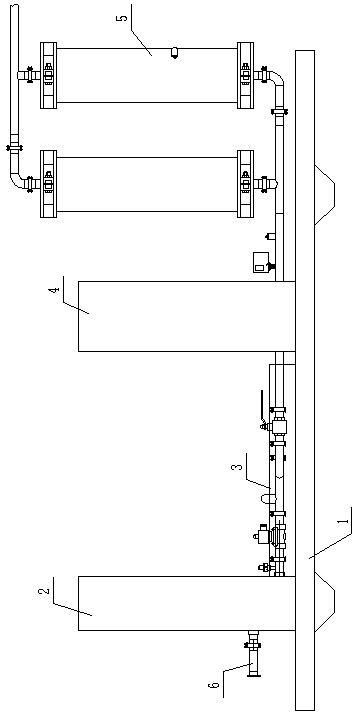

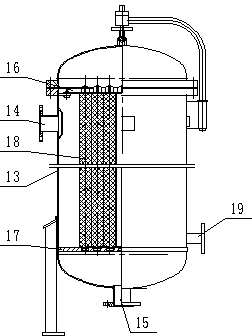

[0017] Such as figure 2 , image 3 As shown, the multimedia filter 2, the dosing box 3, the security filter 4 and the reve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com