A safe and non-toxic oil-in-water emulsified medium ink

An oil-in-water type, safe and non-toxic technology, which is applied in the field of medium ink and ink, and can solve problems such as ink staining on the tip of the pen, easy gelatinization of handwriting, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] According to another aspect of the present invention, there is also provided a method for preparing ink in oil-in-water emulsification, comprising the following steps: S1, injecting water-based solvent, dye and / or pigment color paste into high-shear vacuum homogeneous emulsification In the kettle, open the homogeneous emulsifier to fully dissolve it in the water-based solvent, add a hydrophilic emulsifier, and vacuumize the pressure in the kettle to fully emulsify the components, then open the air inlet valve to restore the inside of the kettle to normal pressure to obtain the water phase emulsion; S2, filter the water phase emulsion, stand still for standby; S3, inject the oily solvent into the vacuum homogeneous emulsification kettle, inject the lipophilic emulsifier, vacuumize, turn on the homogeneous emulsifier, and work for 5 to 100 minutes ; Open the air inlet valve to make the pressure in the kettle return to normal; S4, open the feed port, inject 30-70wt% of the ...

Embodiment 1

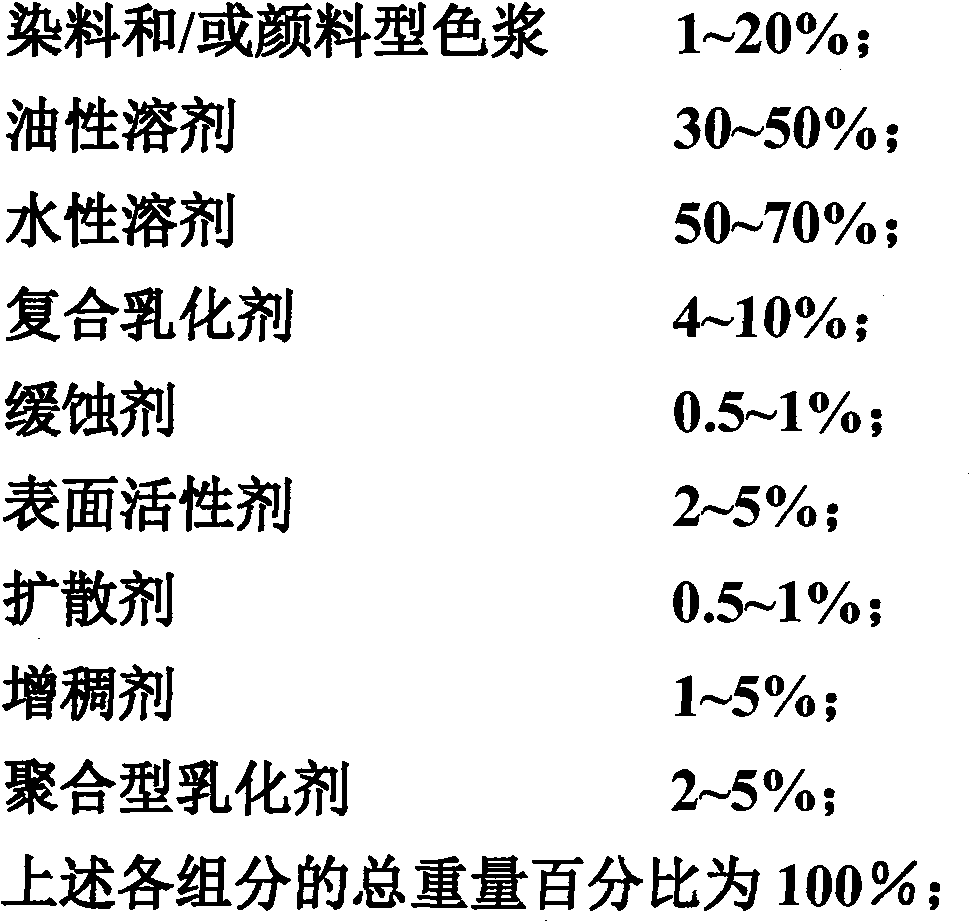

[0021] Production formula of blue oil-in-water emulsification medium ink

[0022] Dye: 2-5% direct sunfast tan; oily solvent: 35-40%, choose one of oxidized castor oil, castor oil, ricinoleic acid; deionized water: 40-50%; ethylene glycol: 10-15% %; emulsifier: 4-10%, select Tween 20, propylene glycol fatty acid ester in the same proportion; corrosion inhibitor: 0.5-1%, select phenylhydrazine triazole; surfactant: 2-5%, select triethanolamine (90%). Diffusion agent: 0.5-1%, choose sodium hexametaphosphate; thickener: 2-4%, choose 950 compound polyurethane thickener; compound emulsifier: 2-3%, choose polyoxyethylene 30 polyhydroxystearin Ester. The total weight of the total proportion of the above components is 100%.

[0023] Step 1: Inject water, dyes, direct sun-resistant tan, ethylene glycol, triethanolamine, phenylhydrazine triazole, sodium hexametaphosphate and other components into the high-shear vacuum homogeneous emulsification kettle, and start the homogeneous emuls...

Embodiment 2

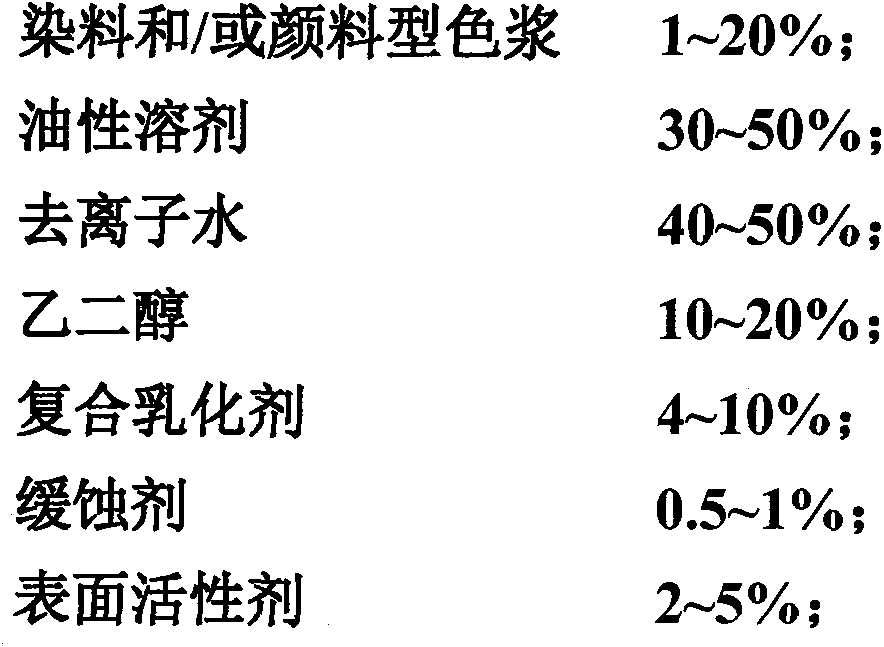

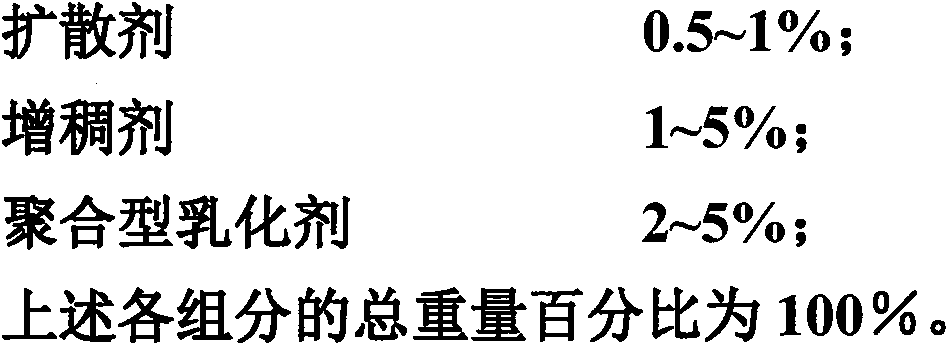

[0035] Production formula of blue oil-in-water emulsified medium ink:

[0036] Dye acid brilliant blue 2-10%, oily solvent 35-50%, choose one of oxidized castor oil, castor oil, ricinoleic acid; deionized 40-50%, ethylene glycol 10-20%; choose Tween 20 Mix emulsifier 4-10% with propylene glycol fatty acid ester in the same proportion; use phenylhydrazine triazole as corrosion inhibitor: 0.5-1%; use triethanolamine (90%) as surfactant: 2-5%; Sodium phosphate: 0.5-1%; thickener is 950 compound polyurethane 1-5%; compound emulsifier is polyoxyethylene 30 polyhydroxystearate: 2-5%; the total weight of the above components is 100 %.

[0037] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com