Microinjection device based on principle of friction

A microinjection and principle technology, applied in enzymology/microbiology equipment, biochemical cleaning equipment, biomass post-treatment, etc., can solve the problems of operator safety hazards, mercury is highly toxic, etc., and achieve high success rate, High positioning accuracy, avoiding installation errors and the effect of thread clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions in the embodiments of the present invention will be described in detail below, obviously, the described embodiments are only some of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

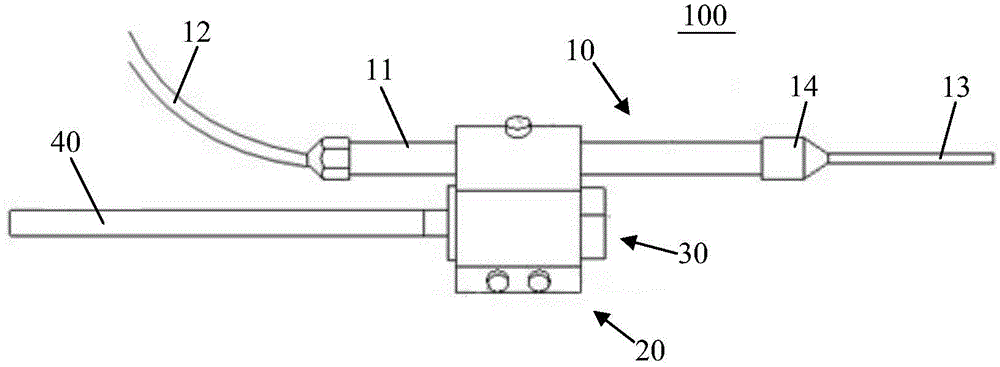

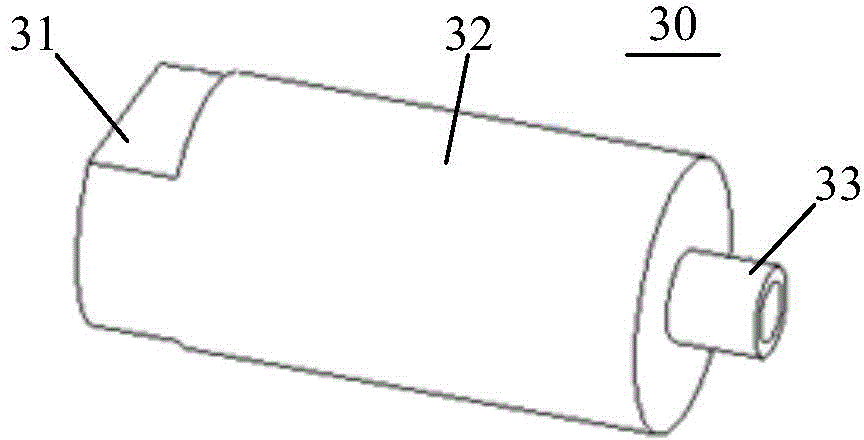

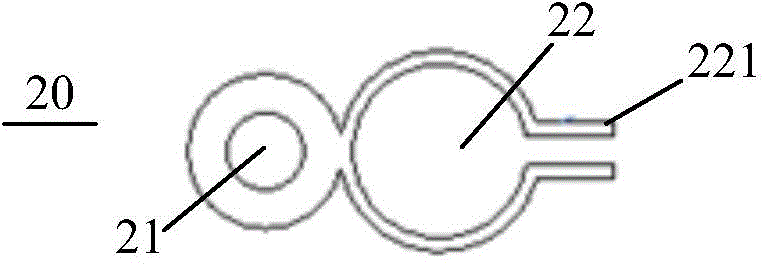

[0021] Such as figure 1 As shown, the microinjection device 100 based on the friction principle of the present invention includes: a syringe 10 , a connector 20 , and a piezoelectric ceramic 30 .

[0022] The syringe 10 is used to provide injection liquid, and the syringe 10 specifically includes: a clamping rod 11 , a nylon tube 12 , a microneedle 13 and a microneedle clamping head 14 . The injection liquid entering the clamping rod 11 from the nylon tube 12 can flow out from the microneedle 13 under the applied force. Wherein, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com