Extremely-thick high-strength high-toughness seabed pipeline steel for ultra-deep sea and manufacturing method of extremely-thick high-strength high-toughness seabed pipeline steel

A technology for submarine pipeline steel and its manufacturing method, which is applied in the field of ultra-thick specification, high-strength and high-toughness submarine pipeline steel and its manufacturing field, which can solve the problems of limited thickness of intermediate billet, large size deviation of seamless steel pipe, long production process, etc., and achieve Improved uniformity, excellent low temperature toughness, and easy composition design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

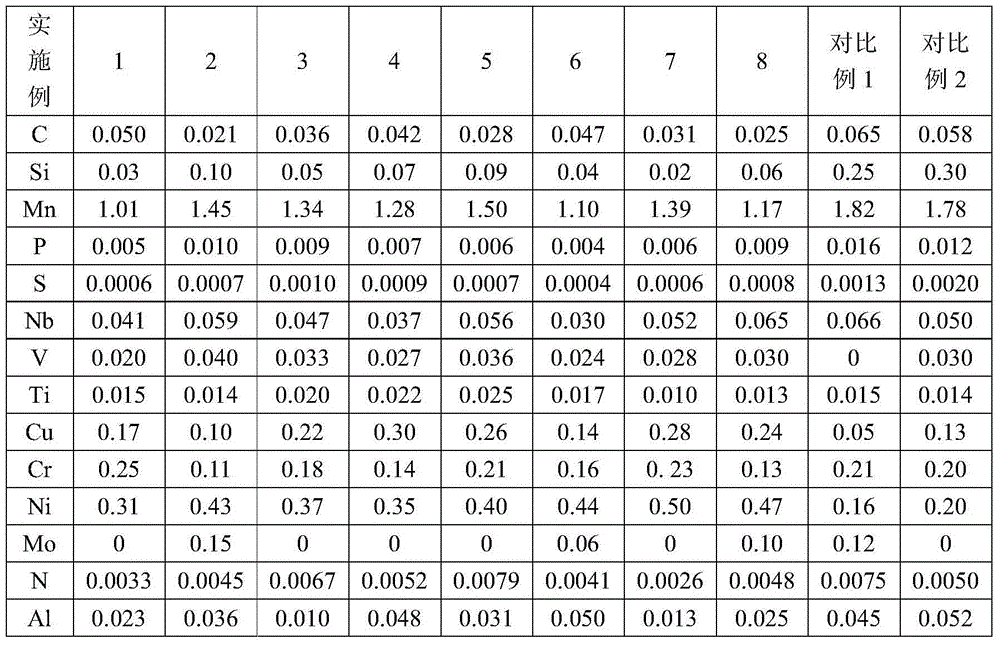

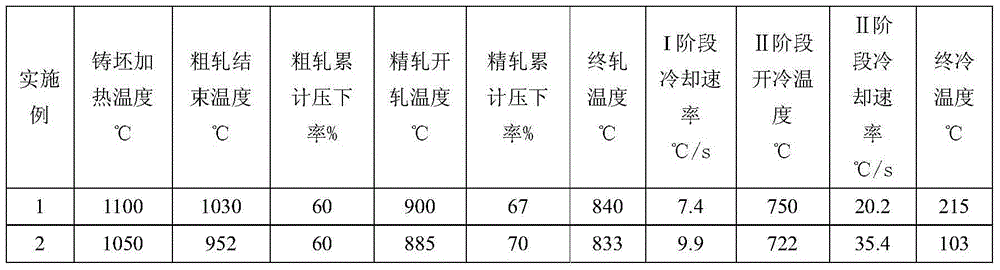

Embodiment 1

[0033] The present invention is an ultra-thick specification high-strength and high-toughness submarine pipeline steel for ultra-deep sea. The weight percentages of the chemical components in the submarine pipeline steel are: C: 0.050%, Si: 0.03%, Mn: 1.01%, P: 0.005 %, S: 0.0006%, Cu: 0.17%, Cr: 0.25%, Ni: 0.31%, Mo: 0%, Nb: 0.041%, V: 0.020%, Ti: 0.015%, Al: 0.023%, N: 0.0033 %, the weight percentages of residual element control are: As≤0.015%, Sn≤0.02%, Sb≤0.01%, Pb≤0.01%, Bi≤0.01%, and the rest are Fe and unavoidable impurities.

[0034] The manufacturing method of the ultra-thick specification, high-strength and high-toughness submarine pipeline steel used in the ultra-deep sea of the present invention comprises the following steps:

[0035] 1) After smelting and casting into slabs, the slabs are uniformly heated to 1100°C;

[0036] 2) Rough rolling is carried out, and the finishing temperature of rough rolling is controlled at 1030° C., the reduction ratio of a single...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, the difference is that:

[0045] The present invention is an ultra-thick specification, high-strength and high-toughness submarine pipeline steel for ultra-deep sea. The weight percentages of the chemical components in the submarine pipeline steel are: C: 0.021%, Si: 0.10%, Mn: 1.45%, P: 0.010 %, S: 0.0007%, Cu: 0.10%, Cr: 0.11%, Ni: 0.43%, Mo: 0.15%, Nb: 0.059%, V: 0.040%, Ti: 0.014%, Al: 0.036%, N: 0.0045 %, the weight percentages of residual element control are: As≤0.015%, Sn≤0.02%, Sb≤0.01%, Pb≤0.01%, Bi≤0.01%, and the rest are Fe and unavoidable impurities.

[0046] The manufacturing method of the ultra-thick specification, high-strength and high-toughness submarine pipeline steel used in the ultra-deep sea of the present invention comprises the following steps:

[0047] 1) After smelting and casting into slabs, the slabs are uniformly heated to 1050°C;

[0048] 2) Carry out rough rolling, and control the f...

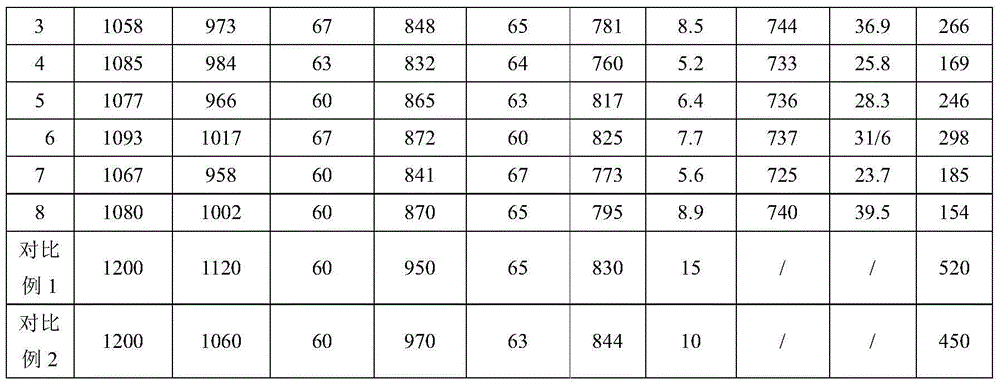

Embodiment 3

[0054] This embodiment is basically the same as Embodiment 1, the difference is that:

[0055]The present invention is an ultra-thick specification high-strength and high-toughness submarine pipeline steel for ultra-deep sea. The weight percentages of the chemical components in the submarine pipeline steel are: C: 0.036%, Si: 0.05%, Mn: 1.34%, P: 0.009 %, S: 0.0010%, Cu: 0.22%, Cr: 0.18%, Ni: 0.37%, Mo: 0%, Nb: 0.047%, V: 0.033%, Ti: 0.020%, Al: 0.010%, N: 0.0067 %, the weight percentages of residual element control are: As≤0.015%, Sn≤0.02%, Sb≤0.01%, Pb≤0.01%, Bi≤0.01%, and the rest are Fe and unavoidable impurities.

[0056] The manufacturing method of the ultra-thick specification, high-strength and high-toughness submarine pipeline steel used in the ultra-deep sea of the present invention comprises the following steps:

[0057] 1) After smelting and casting into a slab, the slab is evenly heated to 1058°C;

[0058] 2) Carry out rough rolling, and control the finish tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com