LNG dispenser

A gas dispenser and gas phase technology, applied in mechanical equipment, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problem that the third check valve has no functional significance, shortens the service life of equipment, and inconveniences equipment Maintenance and repair and other issues, to achieve the effect of convenient follow-up maintenance and repair, shortening the required time, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

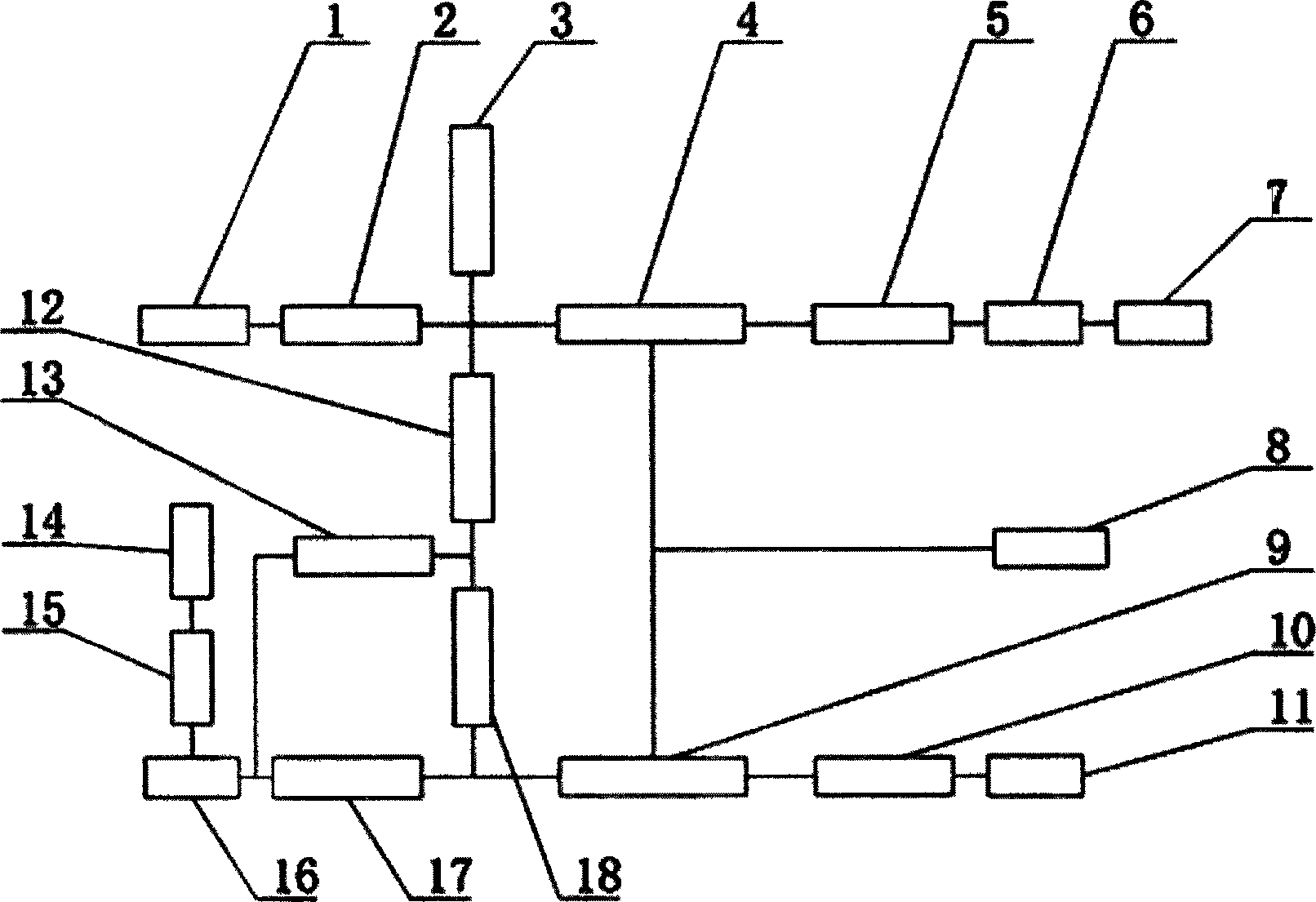

[0014] Such as figure 1 As shown, a LNG filling machine includes a liquid filling pipeline and a return gas return pipeline. One side of the liquid filling pipeline is provided with a liquid inlet 11, and the liquid inlet 11 is connected to the first check valve 10. The first The check valve 10 is connected to the liquid-phase mass flowmeter 9, the liquid-phase mass flowmeter 9 is connected to the first pneumatic valve 17, the first pneumatic valve 17 is connected to the pull-off valve 16, the pull-off valve 16 is connected to the liquid outlet 15, and the liquid outlet 15 Connect the liquid filling gun 14, and install the air return gun 7 on one side of the air ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com