Blade wear resistance test method and device

A test device and anti-wear technology, applied in the direction of testing wear resistance, can solve the problems of accelerated blade wear, time-consuming anti-wear, and inability to quantitatively evaluate anti-wear indicators, and achieve good friction and wear performance and structure. Compact, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

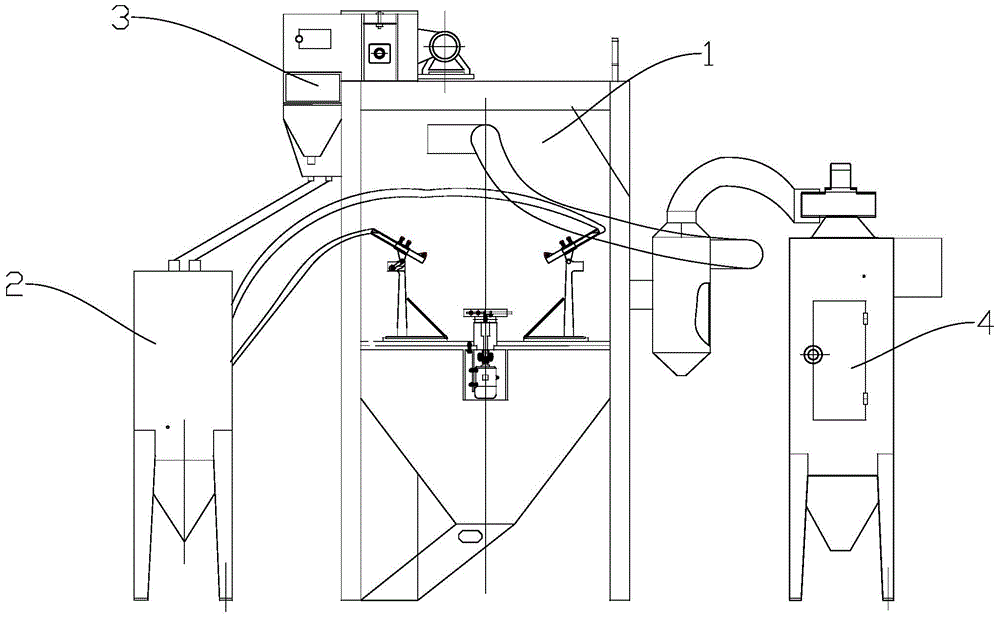

[0025] A test device for blade wear resistance, the device includes a mechanical system and a control system, the mechanical system includes: a shot blasting chamber 1, a shot blaster 2, a shot conveying device 3, and a dust removal device 4; the control system includes an industrial control device computer 5 .

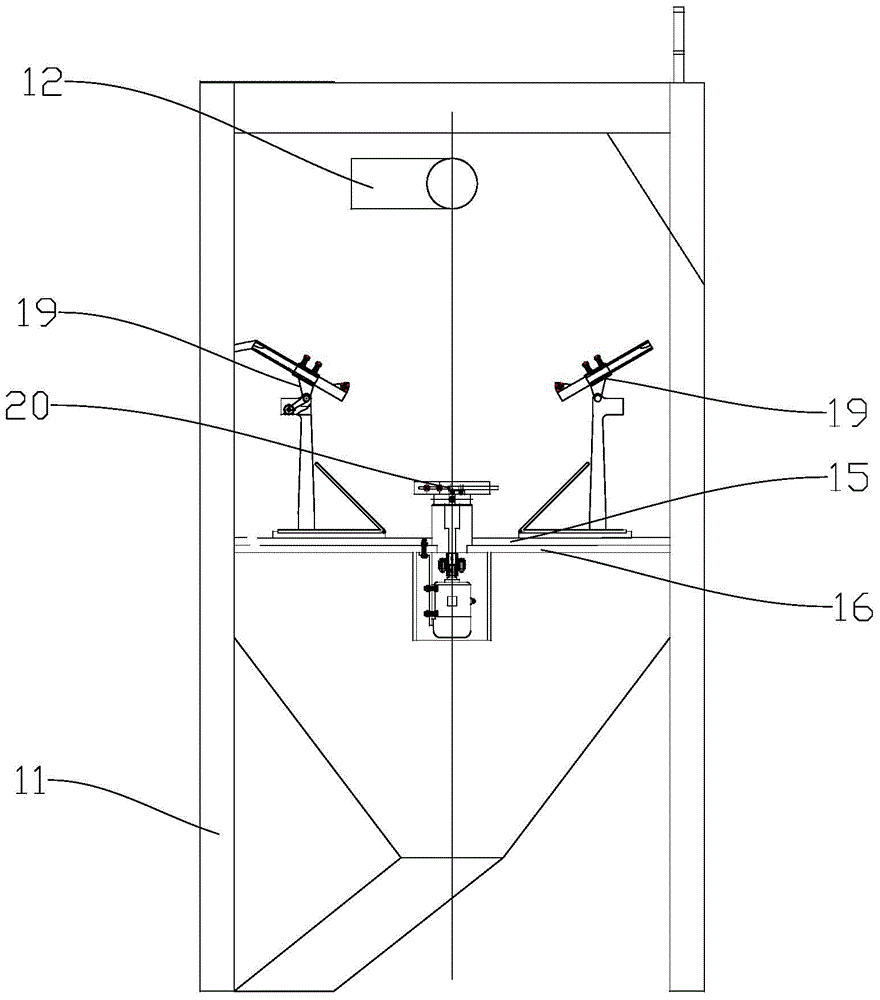

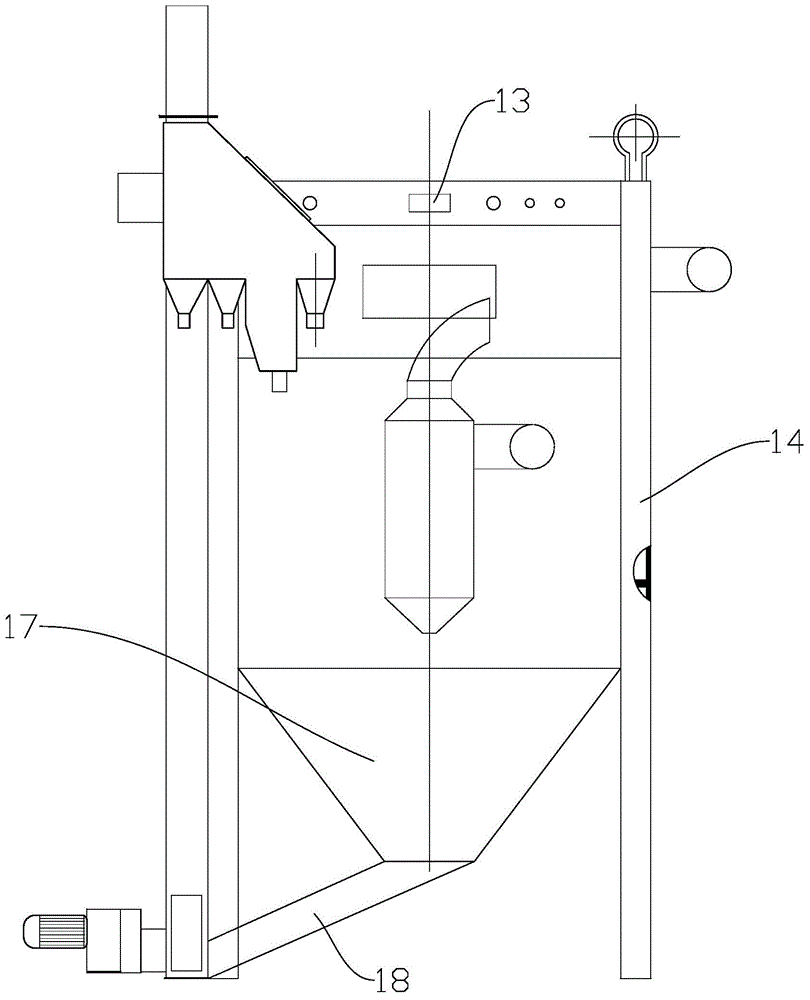

[0026] Such as figure 2 and image 3 As shown, the shot blasting chamber 1 includes: a box body 11, a dust removal port 12, an observation port 13, a hatch 14, a workbench 15, a sand leakage plate 16, a shot recovery device 17, a slide plate 18, a nozzle clamp 19, and a blade clamp 20 .

[0027] The hatch 14 is on the side of the shot blasting chamber 1, and the clamping blades are opened before the test and closed during shot peening. Dust removal port 12 is on the shot blasting chamber 1 top, and is positioned at the adjac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com