Graphene-clad atomic force microscope probe and manufacturing method and application thereof

An atomic force microscope and graphene-coated technology, applied in scanning probe technology, scanning probe microscopy, measuring devices, etc., can solve the problem of difficult removal of PMMA, large radius of curvature of the probe tip, and influence on lateral resolution, etc. Problems, to avoid adverse effects, high resolution, low wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of graphene solution: 5 mg graphene was added to 1 mL water, and ultrasonically dispersed in an ultrasonic cleaner for 10 min to prepare a graphene solution with a concentration of 5 mg / mL;

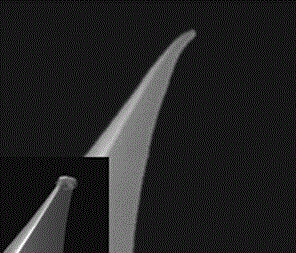

[0039] (2) Preparation of graphene-coated atomic force microscope probe: immerse the tip of the atomic force microscope probe whose substrate is silicon, cantilever and tip are provided with double metal layers of titanium and platinum from the inside to the outside respectively in step (1) In the graphene solution, it was mechanically stirred for 60 s and then taken out to dry naturally. The graphene layer in the prepared graphene-coated AFM probe is 1 layer with a thickness of 0.34 nm.

Embodiment 2

[0041] (1) Preparation of graphene solution: 10 mg graphene was added to 1 mL water, and ultrasonically dispersed in an ultrasonic cleaner for 10 min to prepare a graphene solution with a concentration of 10 mg / mL;

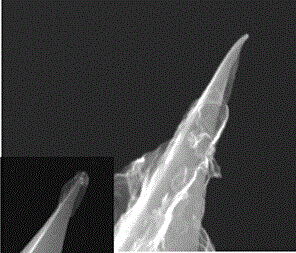

[0042] (2) Preparation of graphene-coated atomic force microscope probe: immerse the tip of the atomic force microscope probe whose substrate is silicon nitride, cantilever and single metal layer of platinum-iridium alloy on the tip into the graphene solution in step (1) , after mechanical stirring for 30s, take it out and let it dry naturally. The prepared graphene-coated AFM probe has three graphene layers with a thickness of 1 nm.

Embodiment 3

[0044] (1) Preparation of graphene solution: 7 mg of graphene was added to 1 mL of water, and ultrasonically dispersed in an ultrasonic cleaner for 10 min to prepare a graphene solution with a concentration of 7 mg / mL;

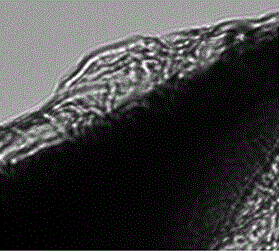

[0045] (2) Preparation of graphene-coated atomic force microscope probe: immerse the tip of the atomic force microscope probe whose substrate is silicon, cantilever and tip are provided with double metal layers of titanium and platinum from the inside to the outside respectively in step (1) In the graphene solution, it was mechanically stirred for 45 s and then taken out to dry naturally. The prepared graphene-coated AFM probe has two graphene layers with a thickness of 0.68 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com