Oil-immersed copper foil capacitor and manufacturing technology thereof

A production process and capacitor technology, applied in the field of capacitors, can solve the problems of loss materials, cost, stability, lack of temperature resistance and technical parameter performance, increase product volume, etc., to achieve low loss, strong passability, and stable voltage resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

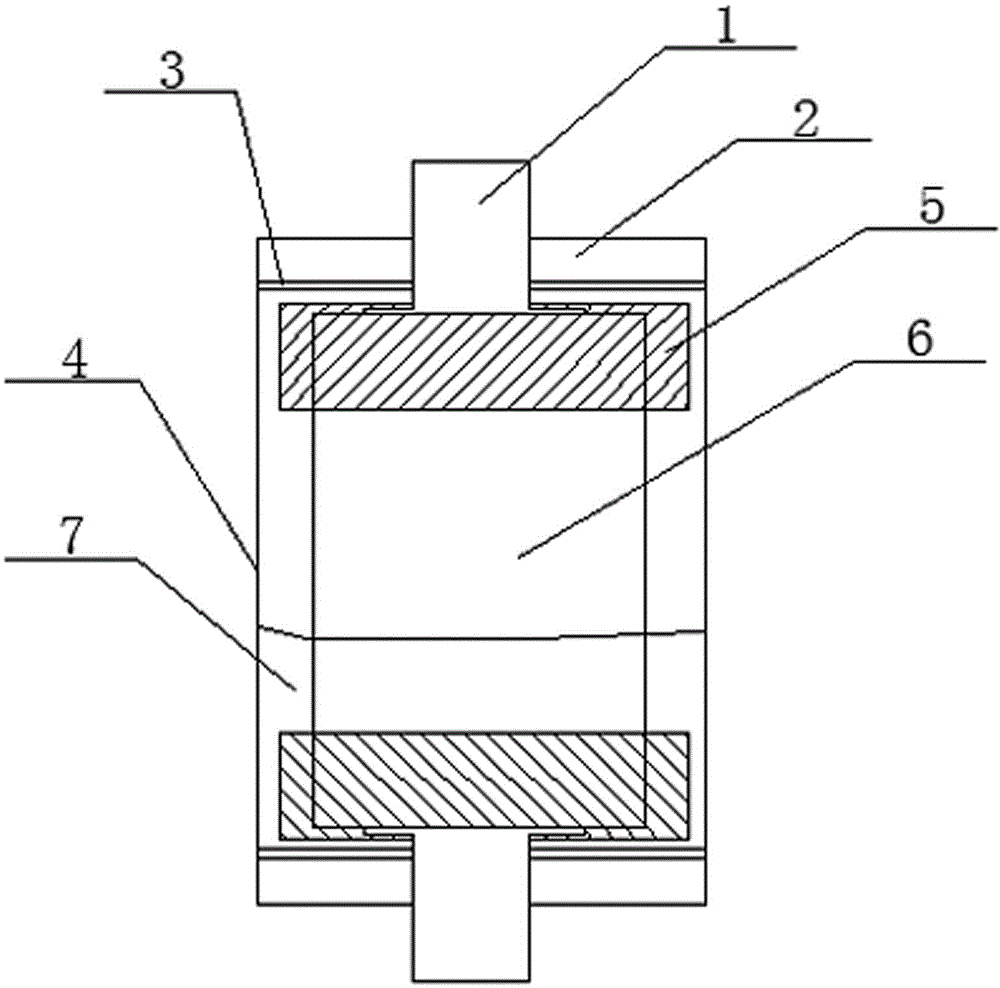

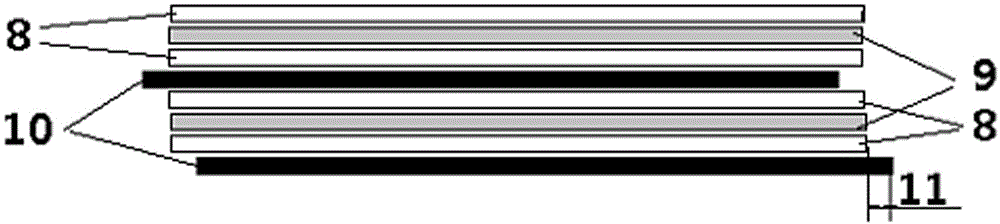

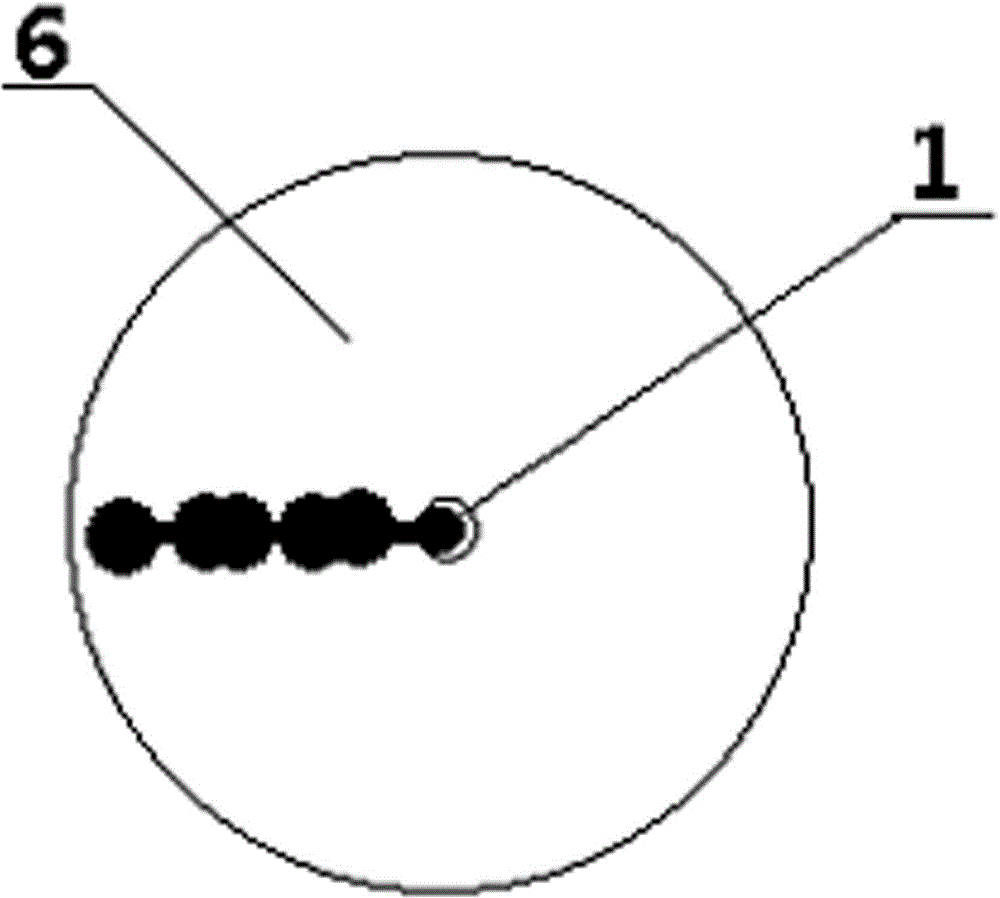

[0031] Embodiment 1: refer to Figure 1-Figure 8 , the specific embodiment adopts the following technical solutions: an oil-immersed copper foil capacitor, including a copper lead-out 1, a sealing plate 3, a casing 4, an insulating sheath 5, a core 6 and an oil 7, and the copper lead-out 1 Welding can be used according to the size of the lead-out area image 3 or bonding Figure 4 On both sides of the core, the insulating sheath 5 is set between the core 6 and the shell 4 to form an insulating belt. The sealing plate 3 passes through the lead-out end 1 and seals and merges with the shell 4, and at the lead-out end of the copper material 1. Weld and seal the contact point, and then perform epoxy 2 perfusion and seal; the core 6 is made of copper foil 10 and composite dielectric film 8, 9 multi-layer winding forming, and then oil 7 impregnation treatment; the said The composite medium film is composed of four layers of polypropylene film 8 and single-layer or multi-layer paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com