Back lighting type image sensor structure capable of improving saturation throughput

An image sensor, back-illuminated technology, applied in the field of image sensors, can solve the problems of low pixel signal saturation capacity and small pixel area, and achieve the effect of improving signal saturation capacity and improving potential well potential swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

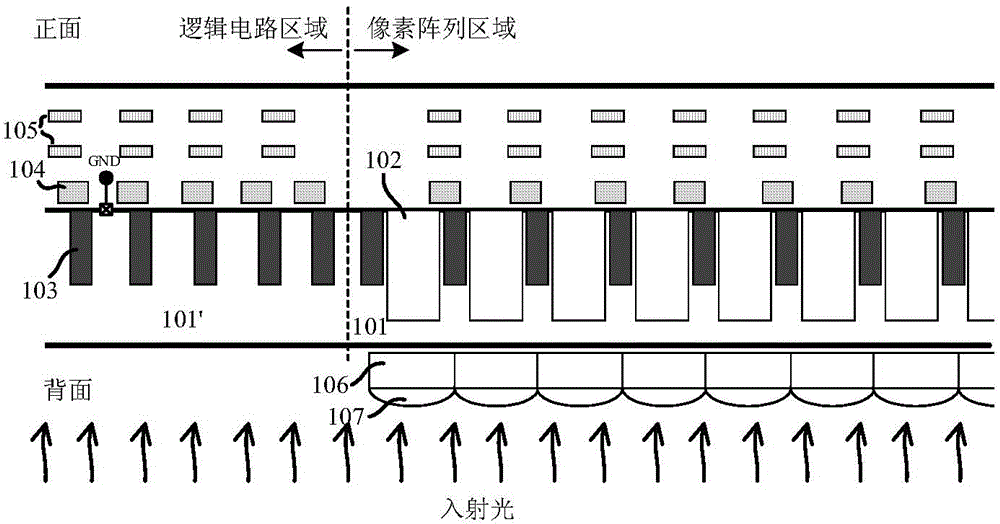

[0016] The preferred embodiment of the structure of the back-illuminated image sensor with improved saturation capacity of the present invention is:

[0017] It includes a logic circuit and a pixel array placed in a semiconductor substrate, an N-type ion ring is arranged in the semiconductor substrate around the pixel array region, and a P-type ion ring is arranged between the pixel array region and the N-type ion ring .

[0018] The N-type ionic ring runs through the thickness of the semiconductor substrate, its upper surface is the front of the substrate, and its lower surface is the back of the substrate, and the width of the N-type ionic ring in the semiconductor substrate is greater than or equal to 0.2um.

[0019] The depth of the P-type ion ring in the semiconductor matrix is greater than or equal to 0.2um, and the width is greater than or equal to 0.2um.

[0020] The distance between the N-type ion ring and the P-type ion ring is greater than or equal to 0um.

[00...

specific Embodiment

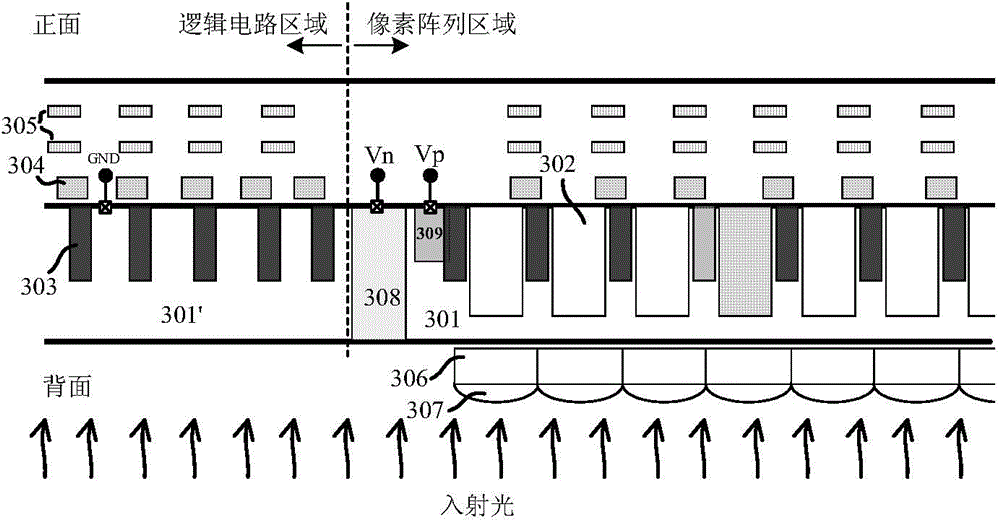

[0025] Schematic diagram of the sectional structure of the back-illuminated image sensor structure with improved saturation capacity of the present invention, as shown in image 3 shown. image 3 Among them, 301 is the semiconductor base in the pixel array area, 301' is the semiconductor base in the logic circuit area, 302 is the photodiode, 303 is the shallow trench isolation area, 304 is the polysilicon gate of the transistor device, 305 is the metal interconnection line, 306 is The color filter on the back side, 307 is the microlens on the back side, 308 is the N-type ion ring, and 309 is the P-type ion ring; wherein, Vn is the external potential of the N-type ion ring 308, and Vp is the external connection of the P-type ion ring 309 potential, GND is the external potential of the semiconductor substrate 301' in the logic circuit region.

[0026] A schematic plan view of the structure of the back-illuminated image sensor with improved saturation capacity of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com