A photovoltaic panel production process and production line

A production process and technology of photovoltaic panels, applied in the field of solar energy applications, can solve the problems of limited use, easy to fall ash, self-weight, etc., and achieve the effect of flexible installation process, strong flexible bending performance, and easy process production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

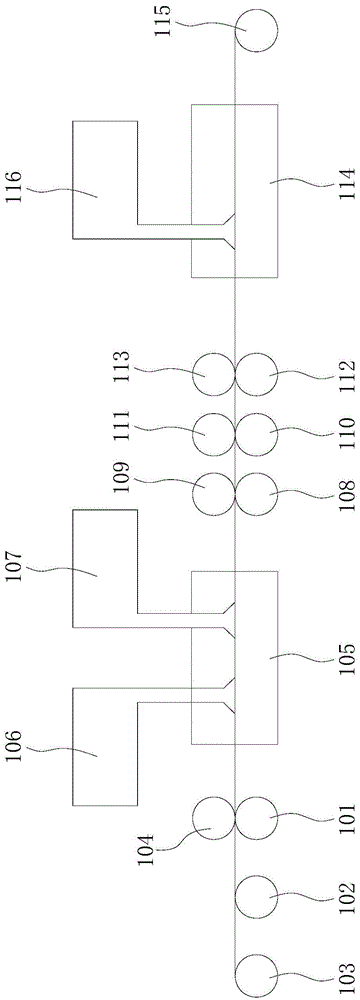

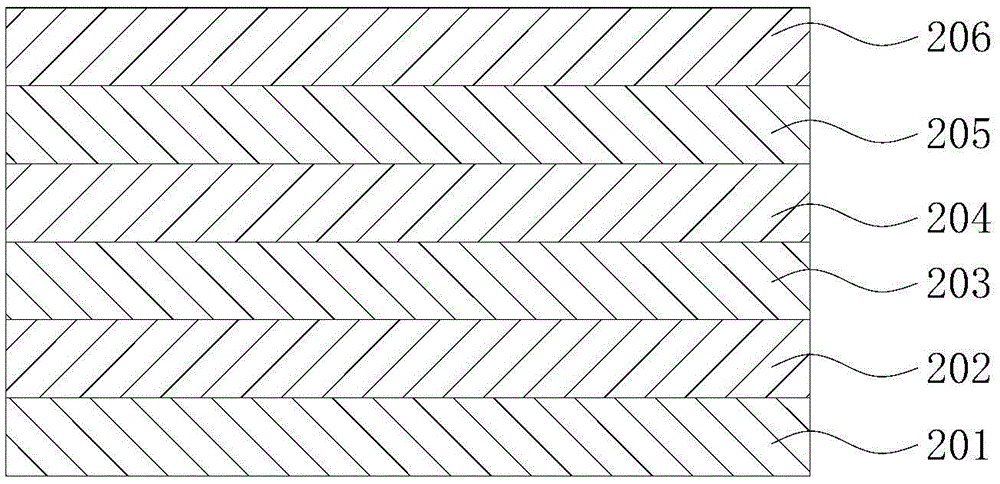

[0034] Attached below figure 1 and figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0035] A photovoltaic panel production process, comprising the following steps:

[0036] a. Provide metal layer, insulating layer and flexible photocell layer;

[0037] b. Place and press the flexible photovoltaic cell layer, insulating layer and metal layer sequentially from top to bottom to form a laminated photovoltaic panel;

[0038] c. Heating and curing the laminated photovoltaic panel to form a photovoltaic panel.

[0039] Wherein, between steps b and c also include:

[0040] b1. Coat the surface of the laminated photovoltaic panel with a PU layer;

[0041] b2. Coating a polymer layer on the surface of the PU layer.

[0042] Wherein, after step b2, before step c also includes:

[0043] d. Coating a photocatalyst layer on the surface of the polymer layer.

[0044] Wherein, the metal layer is stainless steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com