Online sulphur removal maintaining method and system of storage batteries of LAN-based transformer substation

A maintenance system and storage battery technology, which is applied in the repair/maintenance of secondary batteries, secondary batteries, circuits, etc., can solve the problems of unsuitable substations, low degree of automation, etc., and achieve fast data transmission speed, low equipment cost, Simple network configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

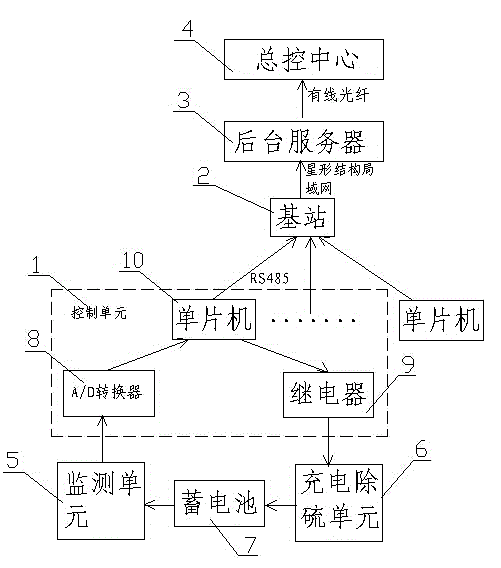

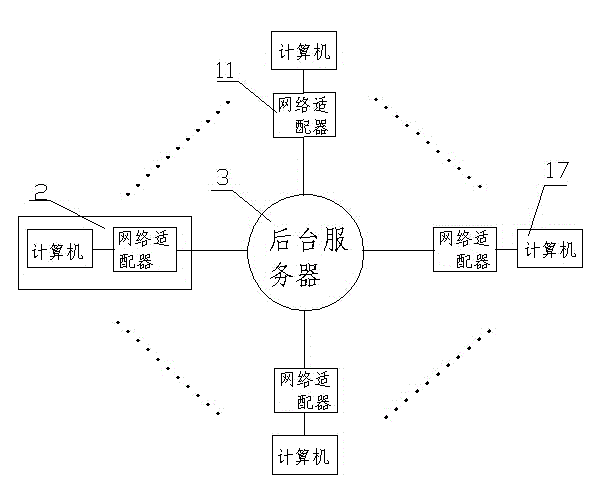

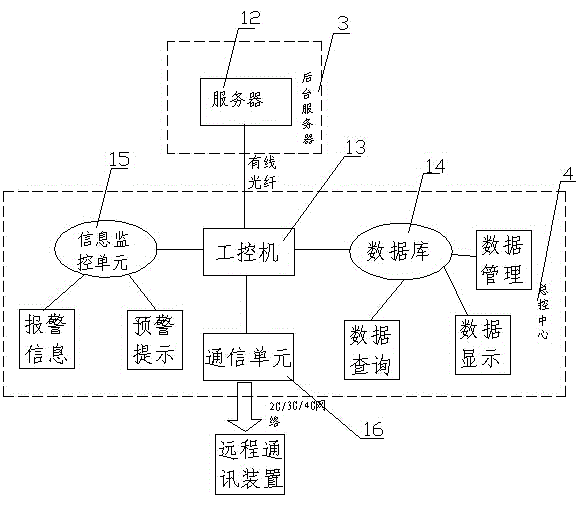

[0031] like figure 1 , figure 2 and image 3 As shown: the present invention provides a LAN-based on-line desulfurization maintenance method for substation batteries. The current, voltage, and internal resistance of the battery 7 are collected and fed back to the control unit 1. When the internal resistance of the battery 7 increases or the capacity is not fully charged When the voltage has risen to full value, the storage battery is charged. If the storage battery 7 has not recovered its performance, the on-line desulfurization is started. The performance information of the storage battery 7 and the desulfurization information of the storage battery 7 are sent to the base station 2, and the base station 2 stores them, and each substation establishes a background server 3, and then establishes a star-shaped local area network to receive the data from most base stations 2 in the substation The information is transmitted to the background server 3, and the background server 3...

Embodiment 2

[0034] like figure 1 , figure 2 and image 3 As shown: the present invention also provides a LAN-based online desulfurization maintenance system for substation storage batteries for the above method, including a monitoring unit 5, a control unit 1, a charging desulfurization unit 6, a storage battery 7, a base station 2, and a background server 3 and the master control center 4, the monitoring unit 5 collects the resistance, voltage and current information of the storage battery 7, the control unit 1 is connected with the monitoring unit 5 and the charging desulfurization unit 6, and the charging desulfurization unit 6 is connected to the storage battery 7, the control unit 1 is connected to the base station 2 through the RS485 communication interface, the base station 2 is connected to the background server 3 through a star LAN, and the background server 3 is connected to the The master control center 4 is connected. The present invention collects the resistance, voltage,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com