VCSEL array packaging structure based on optical encapsulation process and high-power VCSEL laser device of VCSEL array packaging structure

An array packaging and laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as affecting the appearance and structure, complex and cumbersome, and achieve the effect of improving transmittance, avoiding heat, and reducing interface incident loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

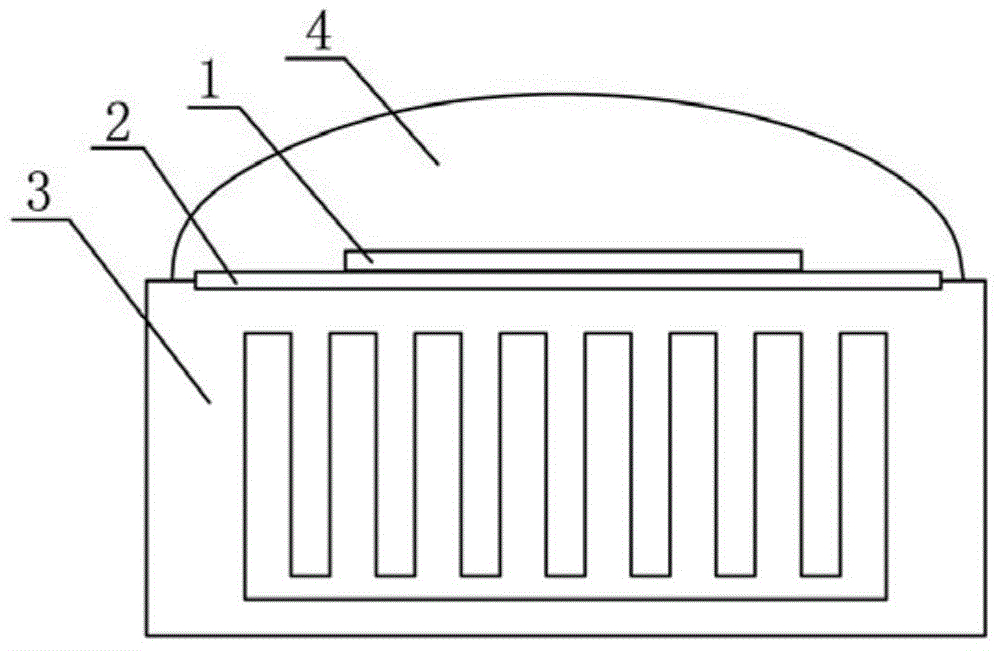

[0026] Such as image 3 As shown, the VCSEL array packaging structure provided by the present invention includes a VCSEL array 1 , a substrate 2 and a laser heat sink 3 , wherein the VCSEL array 1 is packaged on the laser heat sink 3 through the substrate 2 . Specifically, the VCSEL chip is directly welded on the upper surface of the substrate 2 , and then the lower surface of the substrate 2 is welded on the laser heat sink 3 . The substrate 2 has good thermal conductivity, and the heat of the VCSEL array 1 can be conducted out in time through the substrate 2 and the laser heat sink 3 to realize heat dissipation and cooling of the VCSEL array 1 .

[0027] The optical encapsulant 4 is introduced for the first time in the packaging structure provided by the present invention. By directly covering, encapsulating and cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com