Cutting method of glass substrate and manufacturing method of glass substrate

A technology for glass substrates and cutting methods, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of reduced cutting accuracy, reduced glass substrate accuracy, time-consuming, etc., and achieves the effect of good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0070] In this experimental example, the glass substrate was cut while changing the energy density of the laser light and the moving speed of the laser irradiation area relative to the glass substrate, and the cut surface of the cut glass substrate was evaluated.

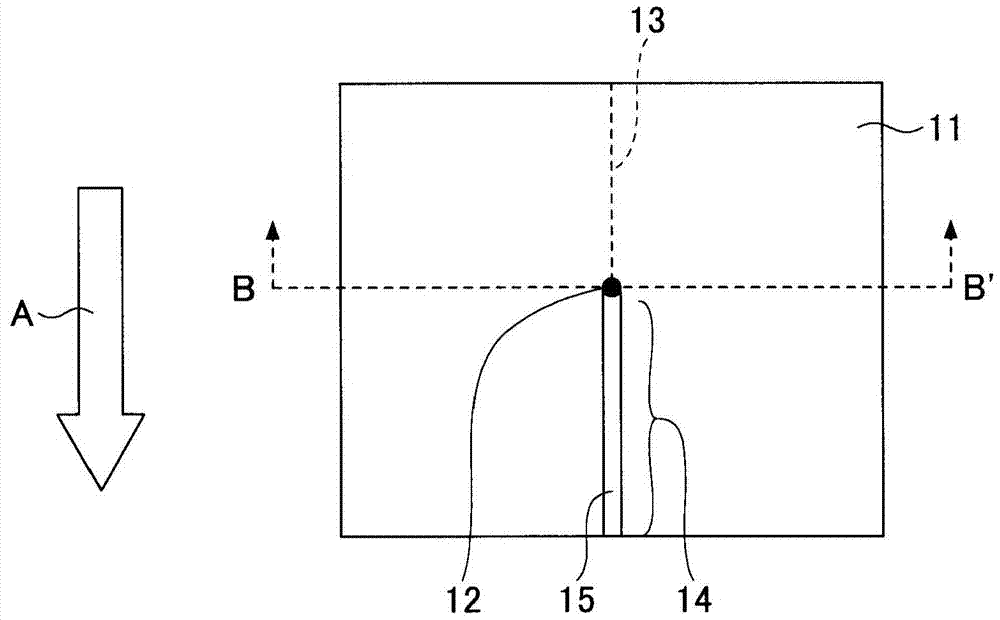

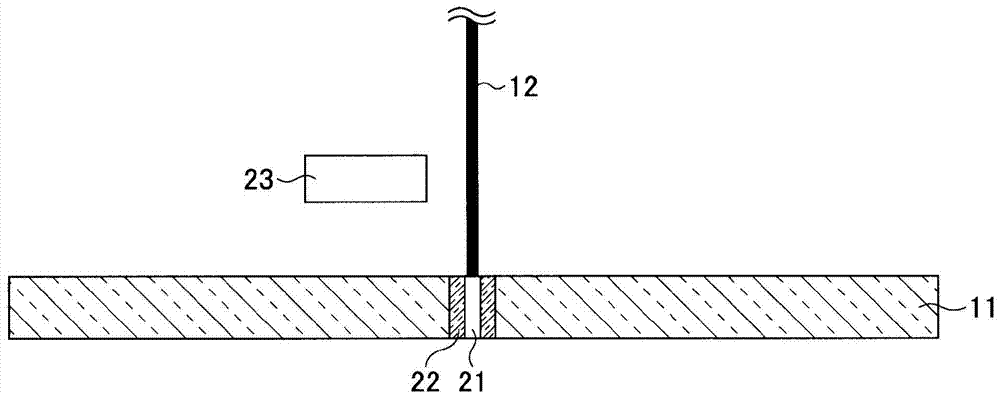

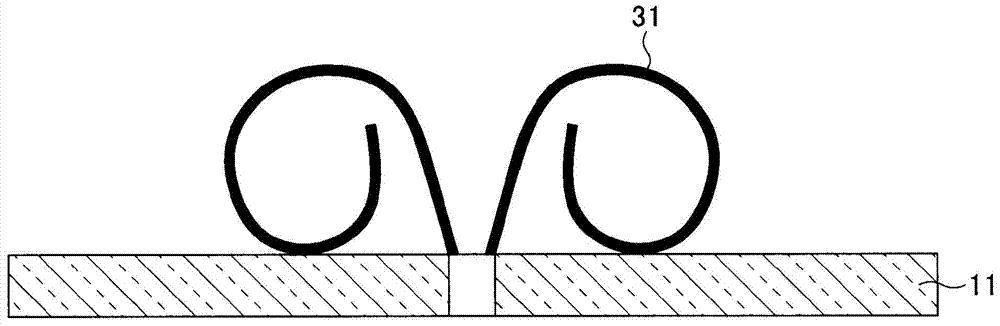

[0071] When cutting glass substrates, by figure 1 In the shown configuration, for a glass substrate (manufactured by Asahi Glass Co., Ltd., trade name: AN100) comprising an alkali-free borosilicate glass with a length of 100 mm, a width of 100 mm, and a plate thickness of 0.1 mm, the glass substrate was transported at a predetermined transport speed. CO is irradiated along the predetermined cutting line with a spot diameter of about 0.3 mm and a predetermined energy density. 2 Laser laser. When cutting, the peripheral temperature (environmental temperature) of the glass substrate was room temperature (25° C.).

[0072] For the glass substrate after cutting, the case where it cannot be cut is evaluated as C; althou...

experiment example 2

[0085] In this experimental example, except that the plate thickness of the glass substrate to be cut was 0.2 mm, the energy density of the laser light and the moving speed of the irradiation area of the laser light relative to the glass substrate were changed in the same manner as in Experimental Example 1 to cut the glass substrate. The cut surface of the cut glass substrate was evaluated.

[0086] The results are shown in Table 2, Figure 5 middle. Figure 5 It is a figure which plotted the result of Table 2.

[0087] Table 2

[0088]

[0089] exist Figure 5 In the shown figure, the straight line X is also the straight line of E=50×t×v (t=0.2 mm) mentioned above.

[0090] In addition, the straight line Y shows the minimum value of the moving speed (here, the conveying speed of the glass substrate) of the irradiated region of the laser light relative to the glass substrate in which precipitates are generated in the cooling process, and in this case, it is 144 (m / ...

experiment example 3

[0093] In this experimental example, except that the plate thickness of the glass substrate to be cut was 0.3 mm, the energy density of the laser light and the moving speed of the irradiation area of the laser light relative to the glass substrate were changed in the same manner as in Experimental Example 1 to cut the glass substrate. The cut surface of the cut glass substrate was evaluated.

[0094] The results are shown in Table 3, Figure 6 middle. Figure 6 It is a figure which plotted the result of Table 3.

[0095] table 3

[0096]

[0097] exist Figure 6 In the diagram shown, the straight line X is also the straight line of E=50×t×v (t=0.3 mm) described above.

[0098] In addition, the straight line Y shows the minimum value of the moving speed (here, the conveying speed of the glass substrate) of the irradiated region of the laser light relative to the glass substrate in which precipitates are generated in the cooling process, and in this case, it is 144 (m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com