Gas shielded automatic welding control device

A gas shielding and control device technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve problems such as difficulty in promotion, and achieve the effects of reducing losses, good environmental resistance and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

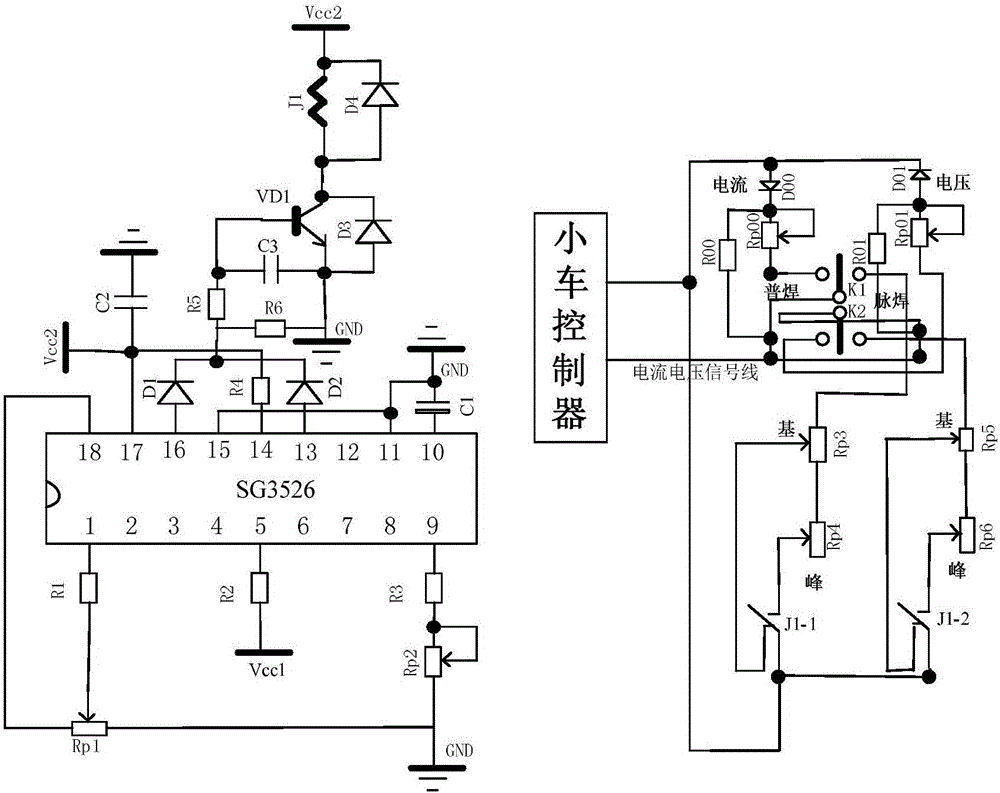

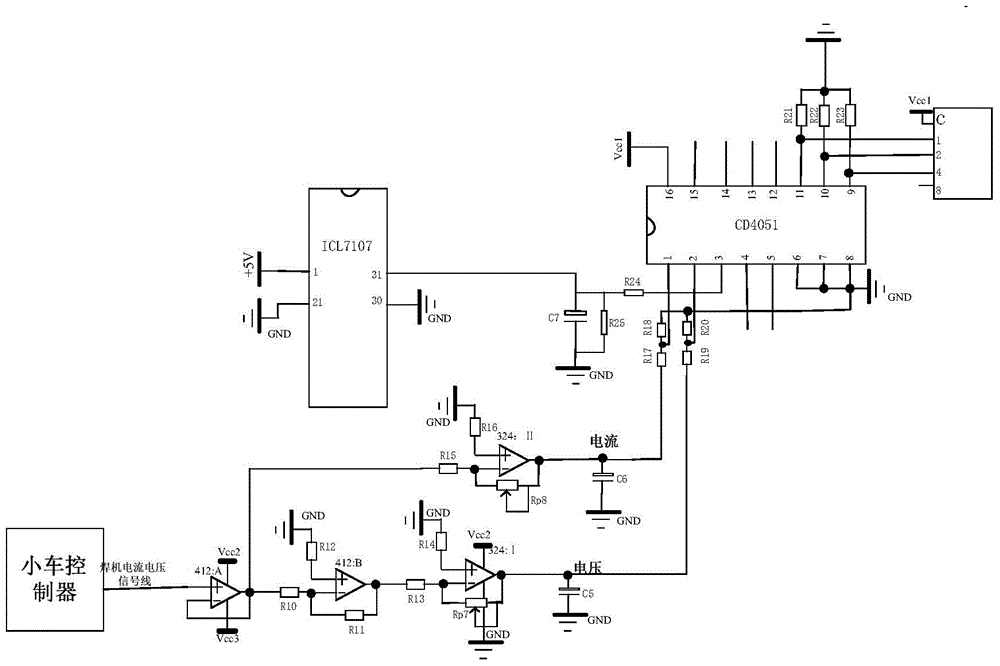

[0033] A specific embodiment of the present invention is an external welding control device on Panasonic silicon rectification welding CO2 welding machine KR2-500 and Huawei HK-100 automatic welding trolley.

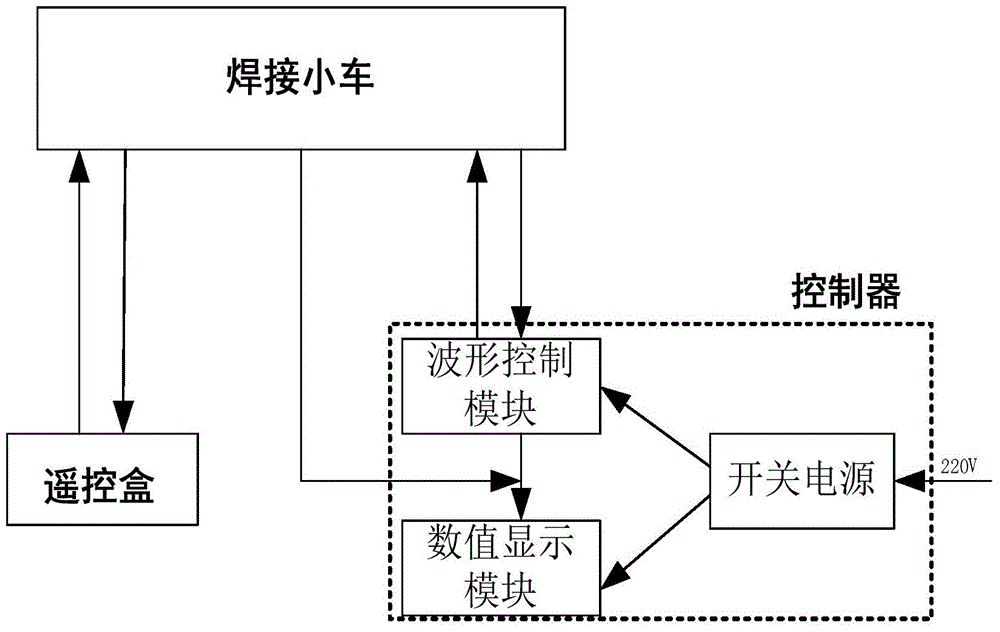

[0034] Set two signal interfaces (A and B) on the side wall of the welding trolley. The A and B signal interfaces correspond to 8-pin and 20-pin interfaces respectively. An 8-pin signal interface (A') is set on the remote control box. The side wall of the controller Set a 20-core signal interface (B'), the two signal transmission cables are 8-core (A") and 20-core multi-core shielded cables, with corresponding signal interfaces at both ends, and the signal interface selection model is CX24- 8 and CX24-20 have two aviation plugs.

[0035] The control device is mainly composed of a relatively independent remote control box and a controller; the remote control box is a square box with two buttons: start and end, and the remote control box is connected to the welding trolley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com