A kind of tea wine and brewing method thereof

A technology for tea wine and tea, which is applied in the preparation of alcoholic beverages, can solve the problems of wasting tea resources, uncoordinated taste, and rapid quality changes, and achieves the effects of avoiding process difficulty, avoiding resource waste, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

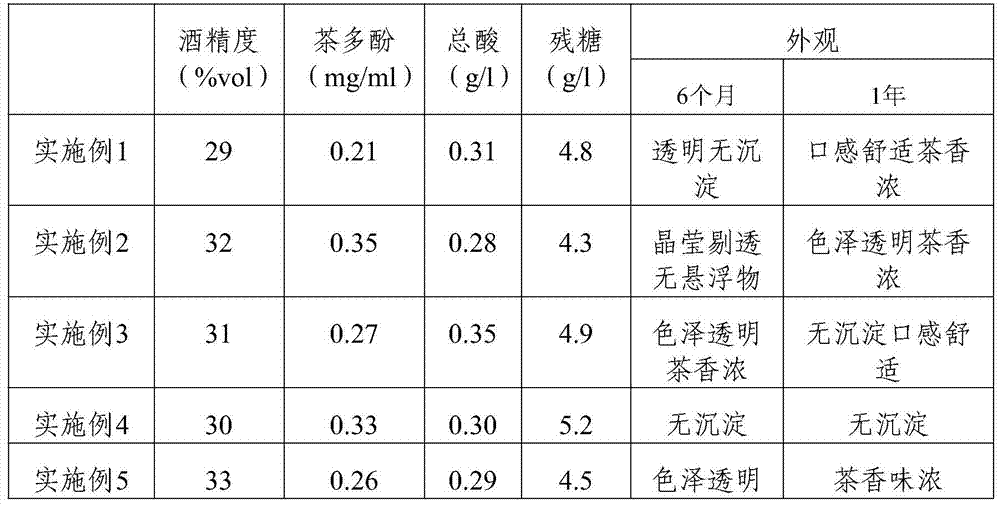

Examples

Embodiment 1

[0031] A kind of tea wine, its raw material composition is tealeaves 40kg, liquor 20kg, starch 10kg, glucoamylase 0.1kg, distiller's yeast 0.2kg.

[0032] Described tealeaves is green tea.

[0033] The alcoholic strength of described liquor is 52%vol.

[0034] Described starch is sweet potato starch.

[0035] The enzyme activity of the glucoamylase is 55000U / ml.

[0036] Described distiller's yeast is Daqu.

[0037] The brewing method of the tea wine comprises the following steps:

[0038](1) Soaking of wine and tea: According to the ratio of raw materials, take white wine and tea leaves, put the tea leaves in a soaking pool, add white wine to it, seal the soaking pool, adjust the temperature to 50°C, and then pump 80°C into it. water, and when pumping in water, use a stirring speed of 70r / min for stirring treatment. When the liquid in the soaking pool reaches two-thirds of the soaking pool, stop pumping in water, and keep stirring at a stirring speed for 5 minutes, then l...

Embodiment 2

[0046] A kind of tea wine, its raw material composition is tealeaves 50kg, liquor 30kg, starch 20kg, glucoamylase 0.6kg, distiller's yeast 0.3kg.

[0047] Described tealeaves is black tea.

[0048] The alcoholic strength of described liquor is 52%vol.

[0049] Described starch is sweet potato starch.

[0050] The enzyme activity of the glucoamylase is 69000U / ml.

[0051] Described distiller's yeast is Daqu.

[0052] The brewing method of the tea wine comprises the following steps:

[0053] (1) Soaking of wine and tea: according to the ratio of raw materials, take white wine and tea leaves, put the tea leaves in the soaking pool, add white wine to it, seal the soaking pool, adjust the temperature to 60°C, and then pump 100°C into it. When the water is pumped in, the stirring speed is 90r / min. When the liquid in the soaking pool reaches two-thirds of the soaking pool, stop pumping in the water, and keep stirring at the stirring speed for 8 minutes, then let it stand Soaking...

Embodiment 3

[0061] On the basis of Example 1, other explanations are the same as Example 1. A kind of tea wine, its raw material components are 43kg of tea leaves, 21kg of white wine, 11kg of starch, 0.2kg of glucoamylase, and 0.21kg of distiller's yeast.

[0062] The enzyme activity of the glucoamylase is 60000U / ml.

[0063] The brewing method of the tea wine comprises the following steps:

[0064] (1) Soaking of wine and tea: according to the ratio of raw materials, take white wine and tea leaves, put the tea leaves in a soaking pool, add white wine to it, seal the soaking pool, adjust the temperature to 55°C, and then pump 90°C into it. water, and when the water is pumped in, the stirring speed is 80r / min. When the liquid in the soaking pool reaches two-thirds of the soaking pool, stop pumping in the water, and continue stirring at the stirring speed for 6 minutes, then let it stand Soaking treatment, and when the soaking temperature in the soaking tank is controlled to be reduced to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com