Novel ultrasonic humidifier

An ultrasonic and humidifier technology, which is applied in the field of new ultrasonic humidifiers, can solve the problems of not being able to automatically follow the resonant frequency of the atomizing sheet, damage the life of the humidifier, and complex circuit structure, so as to avoid dehydration oscillation, dry burning, and safety performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

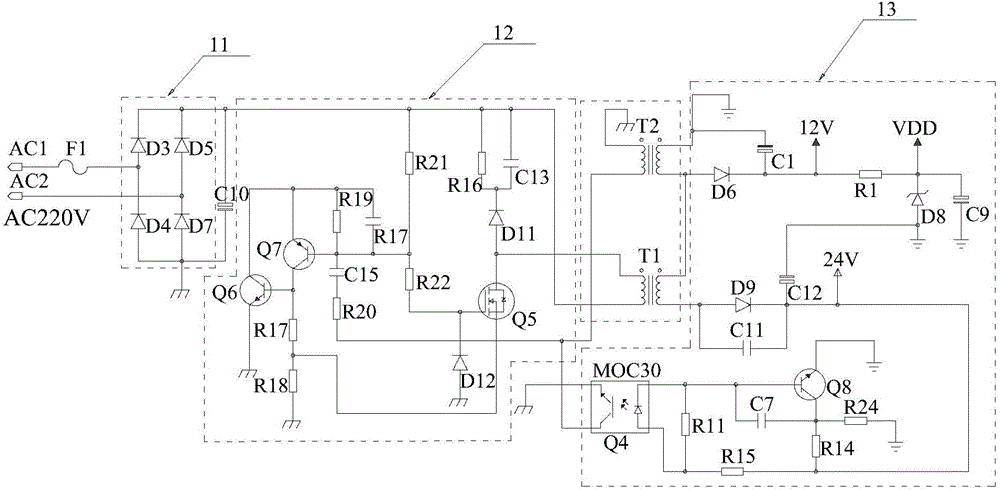

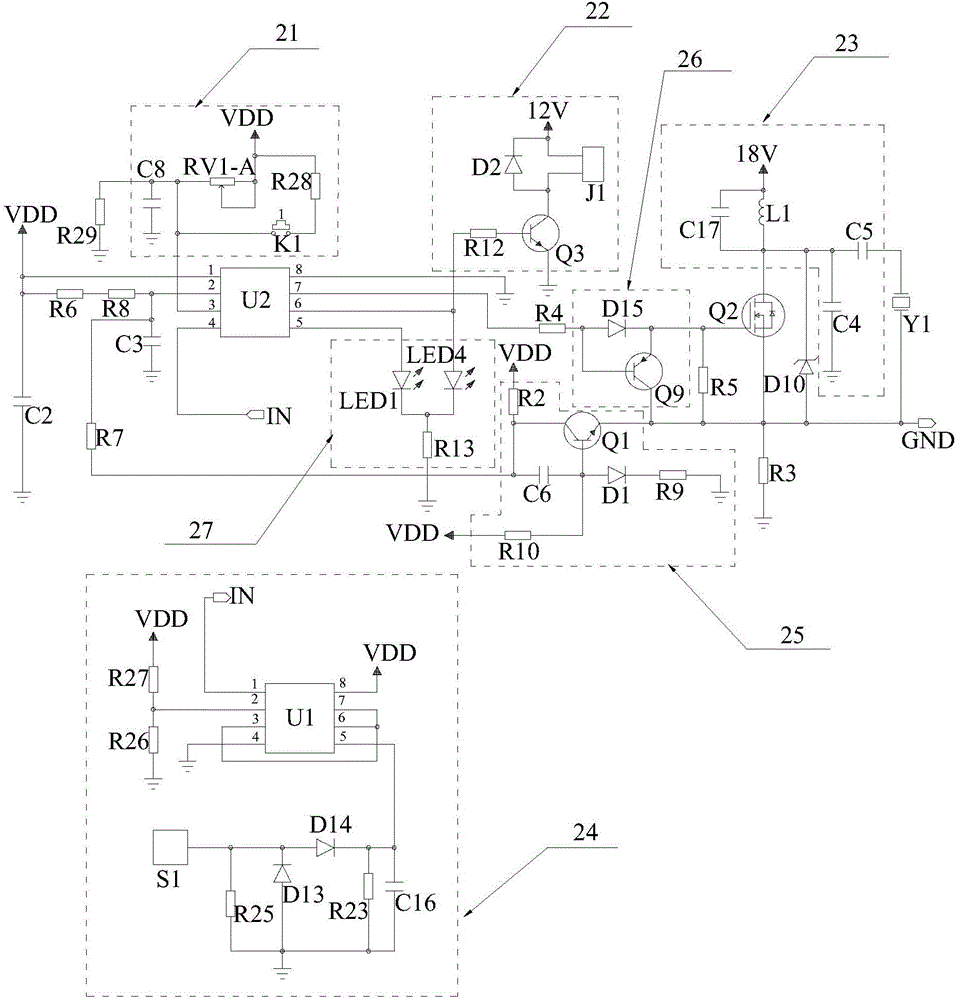

[0026] refer to figure 1 and figure 2 , proposes an embodiment of the novel ultrasonic humidifier of the present invention, the novel ultrasonic humidifier includes a power supply circuit, an ultrasonic oscillation circuit connected to the power output end of the power supply circuit, a pneumatic device 22 connected to the output end of the ultrasonic oscillation circuit, an indicator Circuit 27, atomizing device and water shortage detection circuit 24. The atomizing device is an atomizing sheet Y1, and the pneumatic device 22 includes a fan J1 and a fan drive circuit 26, which atomizes the water into ultrafine particles of one to five microns through the resonance of the atomizing sheet, and diffuses the water mist into the air through the pneumatic device 22. In the air, so as to achieve the purpose of even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com