Shafting dynamic and static characteristic analysis calculating system of large steam turbine generator unit

A steam turbine generator set, characteristic analysis technology, applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of low work efficiency, low accuracy of calculation results, etc., achieve scientific layout, shorten the learning cycle, Reasonably divided effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

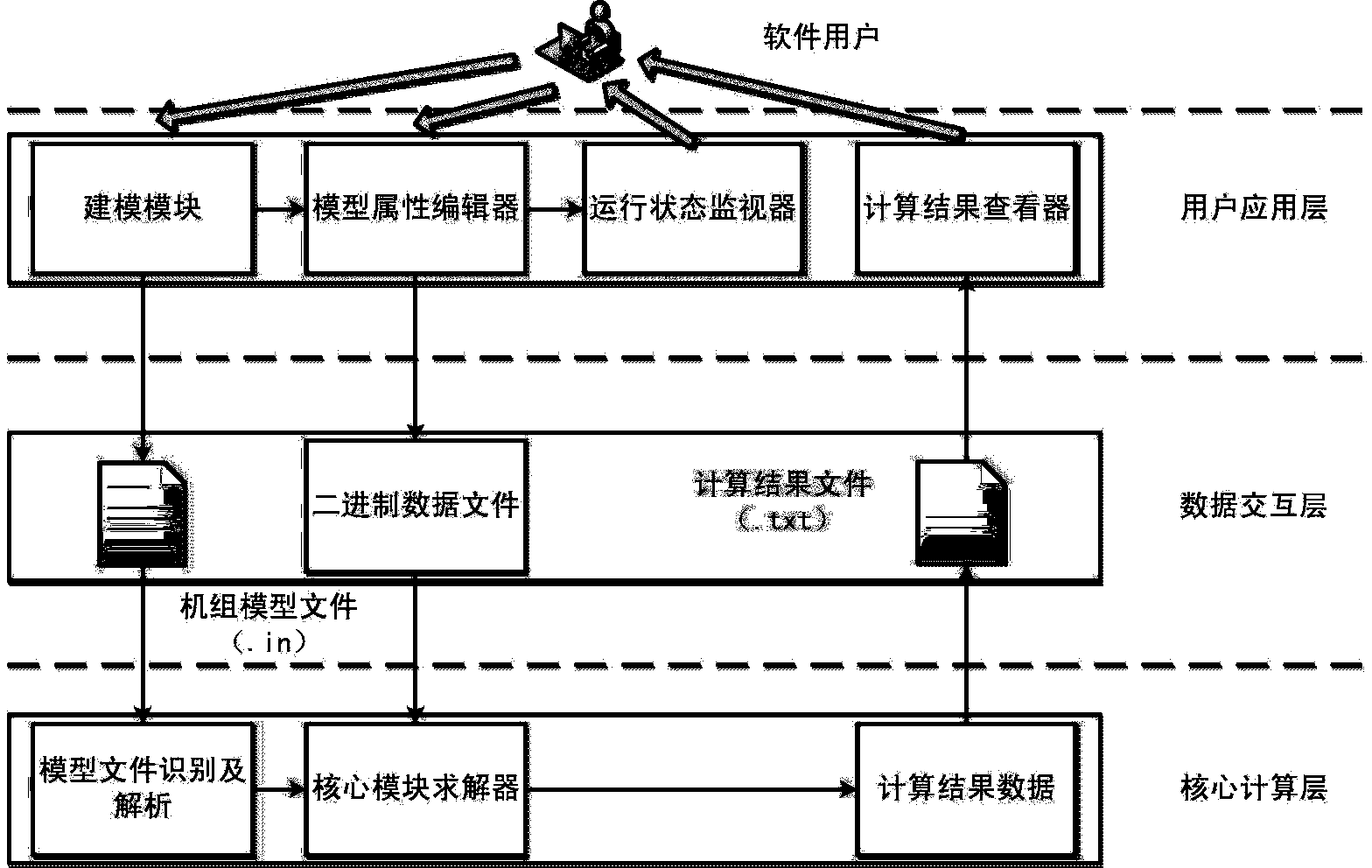

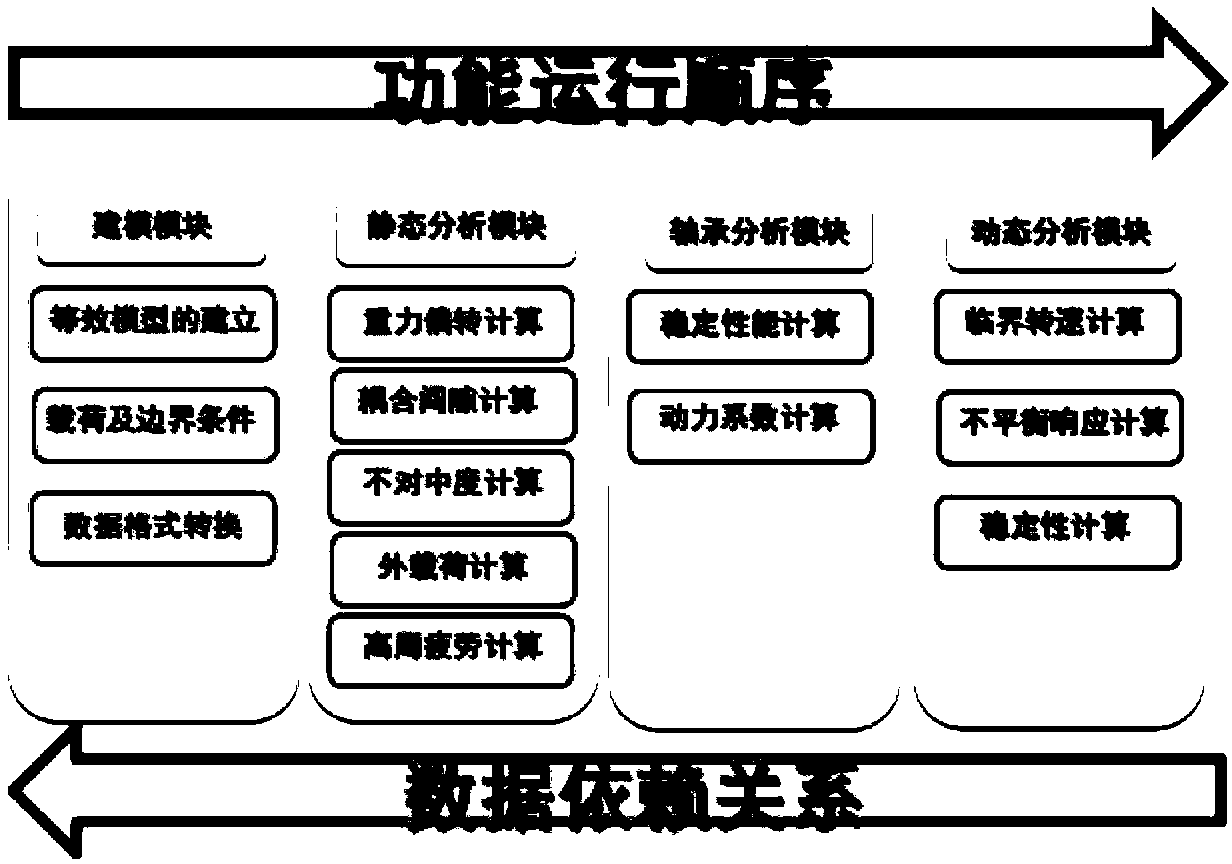

[0038] Specific implementation mode 1: The basic structure diagram of the RDC system in this implementation mode is as follows figure 1 Shown: Analysis and calculation system for dynamic and static characteristics of shafting of large turbogenerator set, which includes:

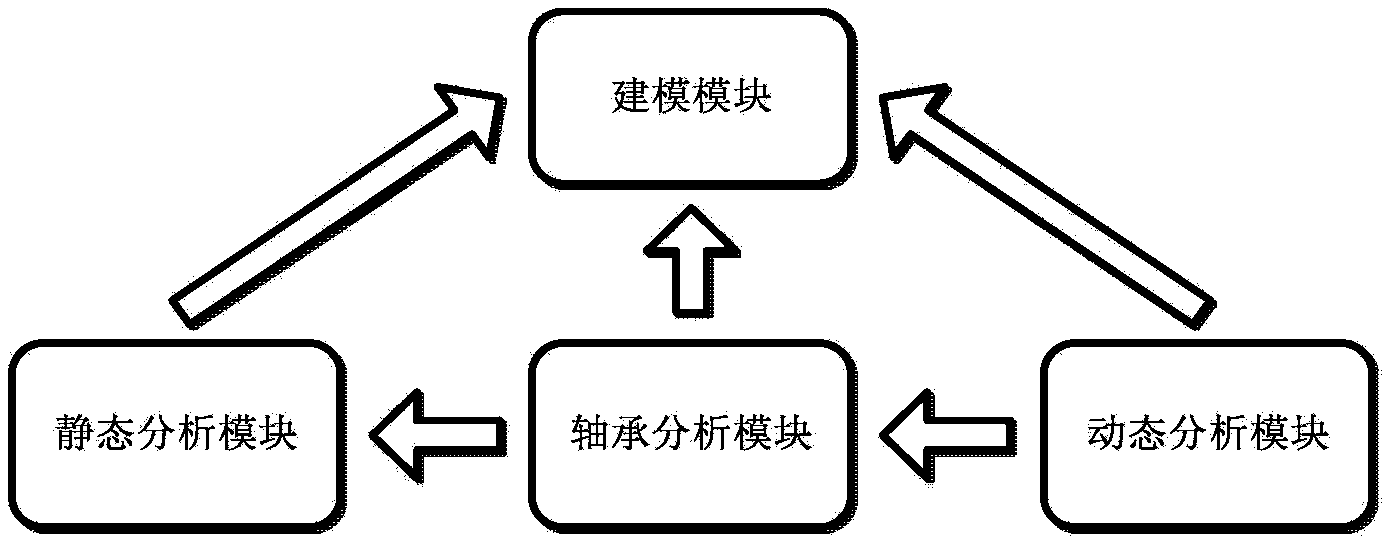

[0039] Modeling modules for building rotor mechanics models;

[0040] It is used to call the rotor mechanics model data of the modeling module and the bearing load and elevation data of the static analysis module, and then calculate the steady-state data and dynamic coefficient of the bearing under constant temperature and variable temperature according to the Reynolds equation, and store the dynamic coefficient of the bearing analysis module;

[0041] A dynamic analysis module used to call the rotor mechanics model data of the modeling module, the shaft load data of the static analysis module and the dynamic coefficient of the bearing analysis module, and analyze the critical speed of the rotor, unbalance r...

specific Embodiment approach 2

[0050] Embodiment 2: This embodiment differs from Embodiment 1 in that: the rotor mechanics model is established by splicing building blocks with equivalent stiffness diameter and shaft section mass.

[0051] After the creation process starts, the system provides a default shaft segment, and the user can build a complete rotor mechanics model by adding new shaft segments or bearings forward and backward with the default shaft segment as the starting point.

[0052] The modeling operation of the rotor model in the RDC system is mainly completed by two parts: the model editing display area of the main interface of the RDC system and the attribute editor of the main interface of the RDC system. During the modeling operation, in addition to the above two areas, the basic operations on the model axis section also need to cooperate with the operations on the modeling toolbar in the menu bar.

[0053] The different states it is in are marked to indicate the user to complete the mod...

specific Embodiment approach 3

[0057] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the modeling module includes an equivalent model establishment sub-module, a load and boundary condition sub-module, and a data format conversion sub-module;

[0058] The sub-module for establishing the equivalent model is used to model the geometric model of the rotor in the form of the length and rigidity diameter of each shaft section of the rotor, and convert it into a mechanical model, and connect the shaft sections together in the form of building blocks, Build the whole rotor, assign the material properties to the mechanical model and determine the bearing position and bearing size;

[0059] Wherein, the stiffness diameter in the equivalent model is calculated using the 45° method, and the specific steps of the method are:

[0060] (1) Draw a 45° line tangent to the guide circle at the abrupt position of the shaft and the impeller;

[0061] (2) The intersection point of two inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com