Parallel-connection type integrated packaging large-power current transforming module

An integrated packaging, high-power technology, applied in the conversion of AC power input to DC power output, output power conversion devices, conversion equipment structural components and other directions, can solve the problem of large size, poor service life of high-power IGBT inverter modules, High-power IGBT chip heat dissipation and other problems, to avoid damage, improve service life, and reduce maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

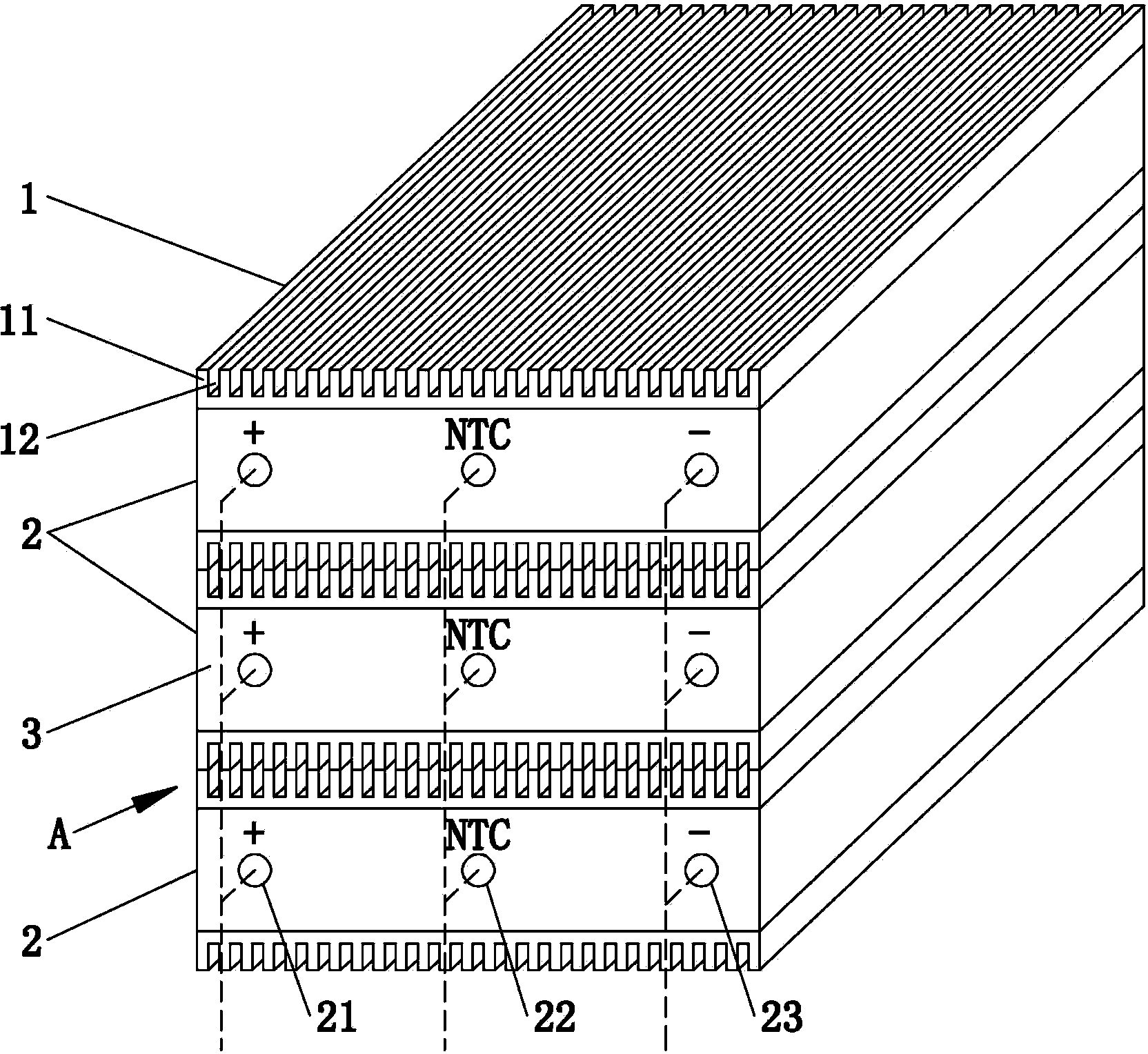

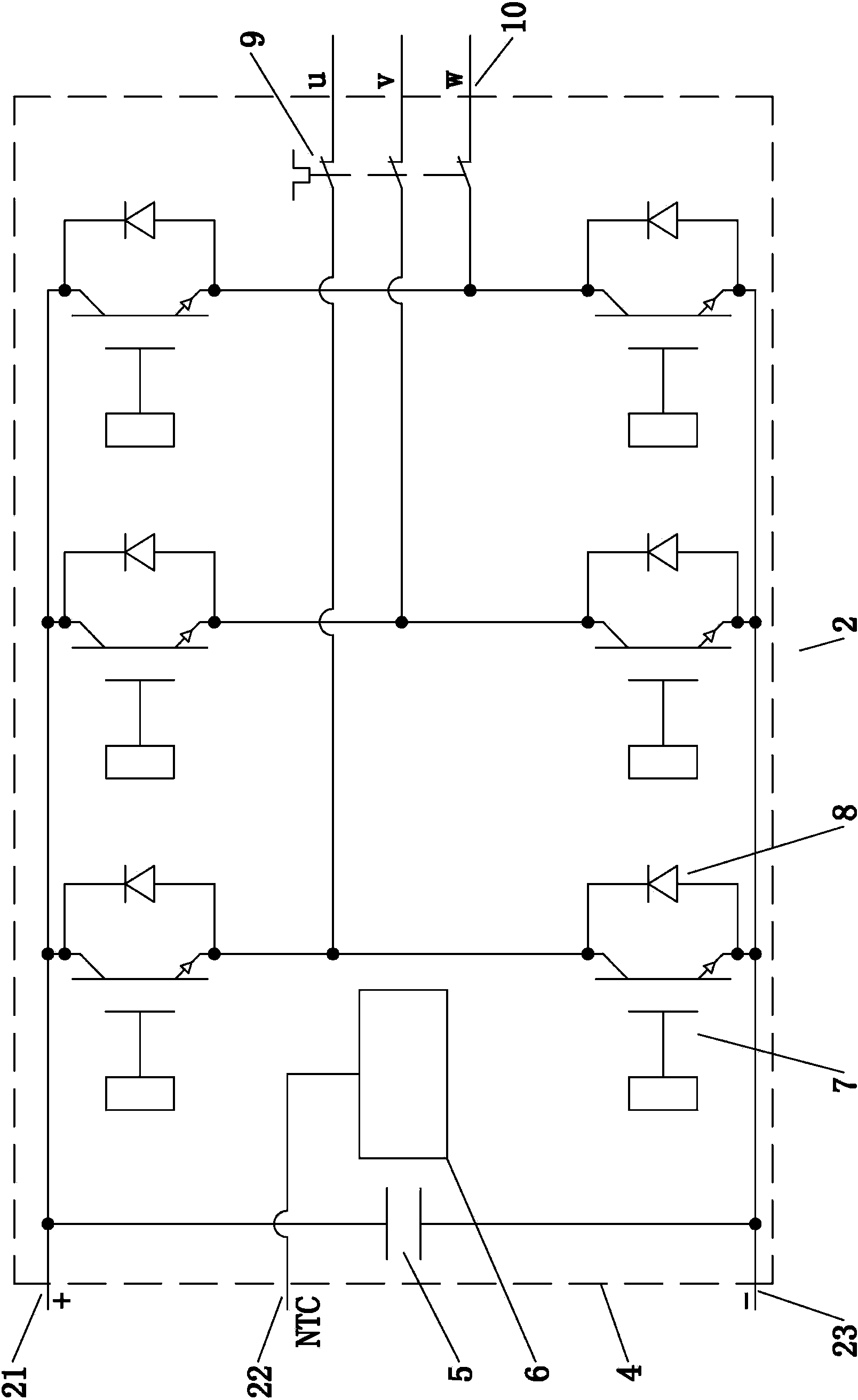

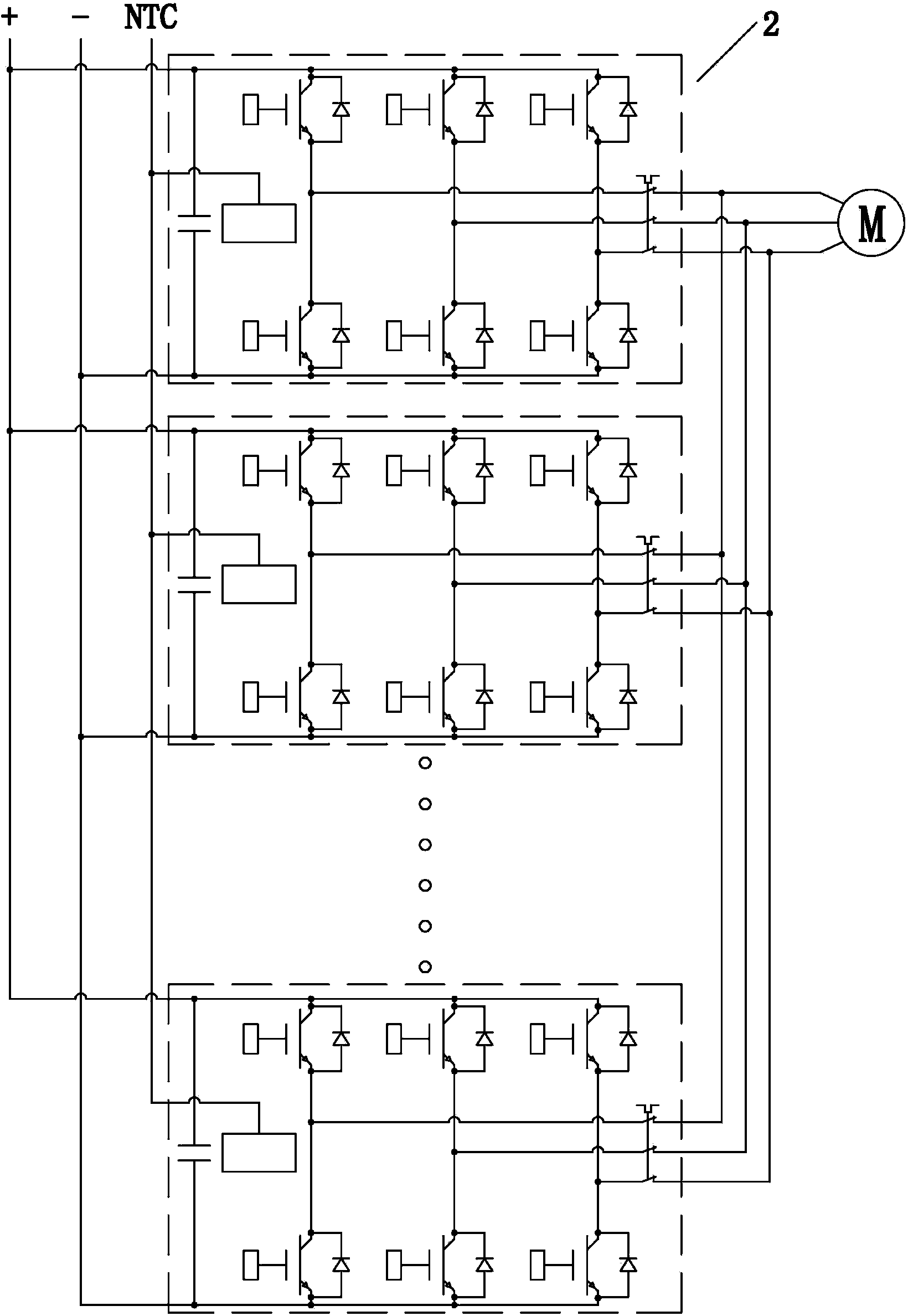

[0026] Embodiment one, see figure 1 and figure 2 As shown, a parallel integrated packaging high-power converter module includes at least two low-power sub-converter modules 2 that are connected in parallel and stacked vertically (in this embodiment, three low-power sub-converter modules 2 are stacked vertically And connected in parallel, according to actual needs, it can be made by stacking two, four, five, etc. together to form a high-power converter module), the low-power sub-converter module 2 includes the circuit part 4, insulation and heat conduction Layer 3 and radiator 1, the circuit part 4 is packaged in the insulating and heat-conducting layer 3, the circuit part 4 includes a plurality of IGBT chips 7 and a plurality of diodes 8, the radiator 1 is arranged on the outer surface of the insulating and heat-conducting layer 3, and the insulating and heat-conducting layer 3 The surface is also provided with a DC input terminal and an AC output terminal, and the circuit p...

Embodiment 2

[0035] Embodiment two, the difference with embodiment one is: see Figure 4 As shown, each small-power sub-converter module 2 is connected in parallel and connected together in a horizontal arrangement.

Embodiment 3

[0036] Embodiment three, the difference with embodiment one is: see Figure 5 and Figure 6 As shown, heat dissipation fins 11 are provided on the surface of the heat dissipation body 1, and water flow channels 13 are formed between the heat dissipation fins 11. By injecting water or cooling liquid into the water flow channels 13, liquid cooling can be realized for small power The sub-converter module 2 dissipates heat. The water flow channel 13 can be a slender channel with openings at both ends. When the upper and lower low-power sub-conversion modules 2 are stacked, the two openings at the head and tail of the upper and lower low-power sub-conversion modules 2 can be connected in series through the water pipe 40, and the upper and lower sub-conversion modules 2 can be connected in series. A seal ring 30 should be provided between the two low-power sub-converter modules 2 , and the surface of the heat sink 1 on the outside should be connected to the seal ring 30 and the cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com