Atmospheric pressure large-area uniform space plasma generating device

A plasma and generating device technology, applied in the field of plasma generating devices, can solve the problems of unstable discharge, difficulty in adjusting the distance between dielectric tubes, etc., and achieve the effects of stable operation, excellent adjustability, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

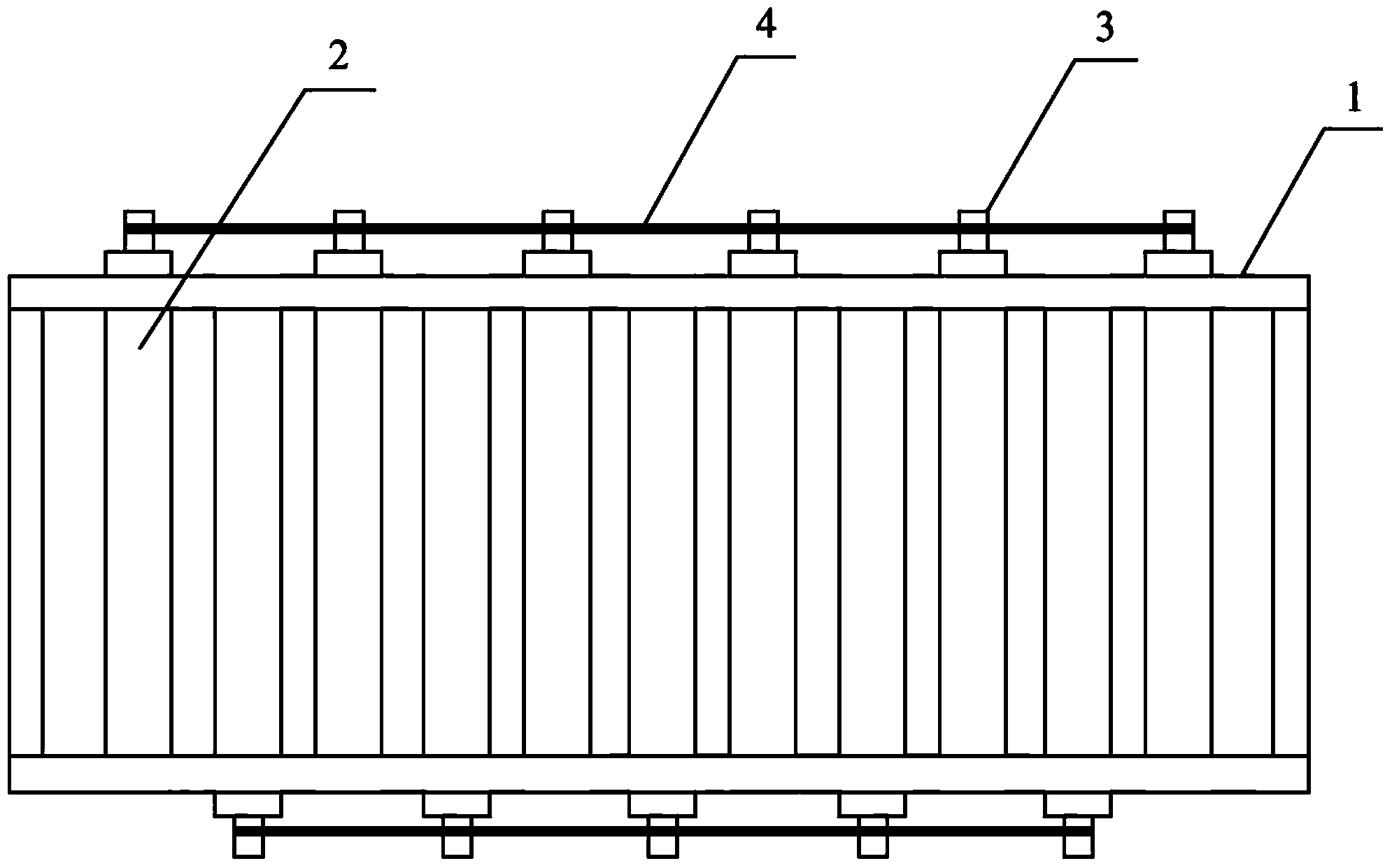

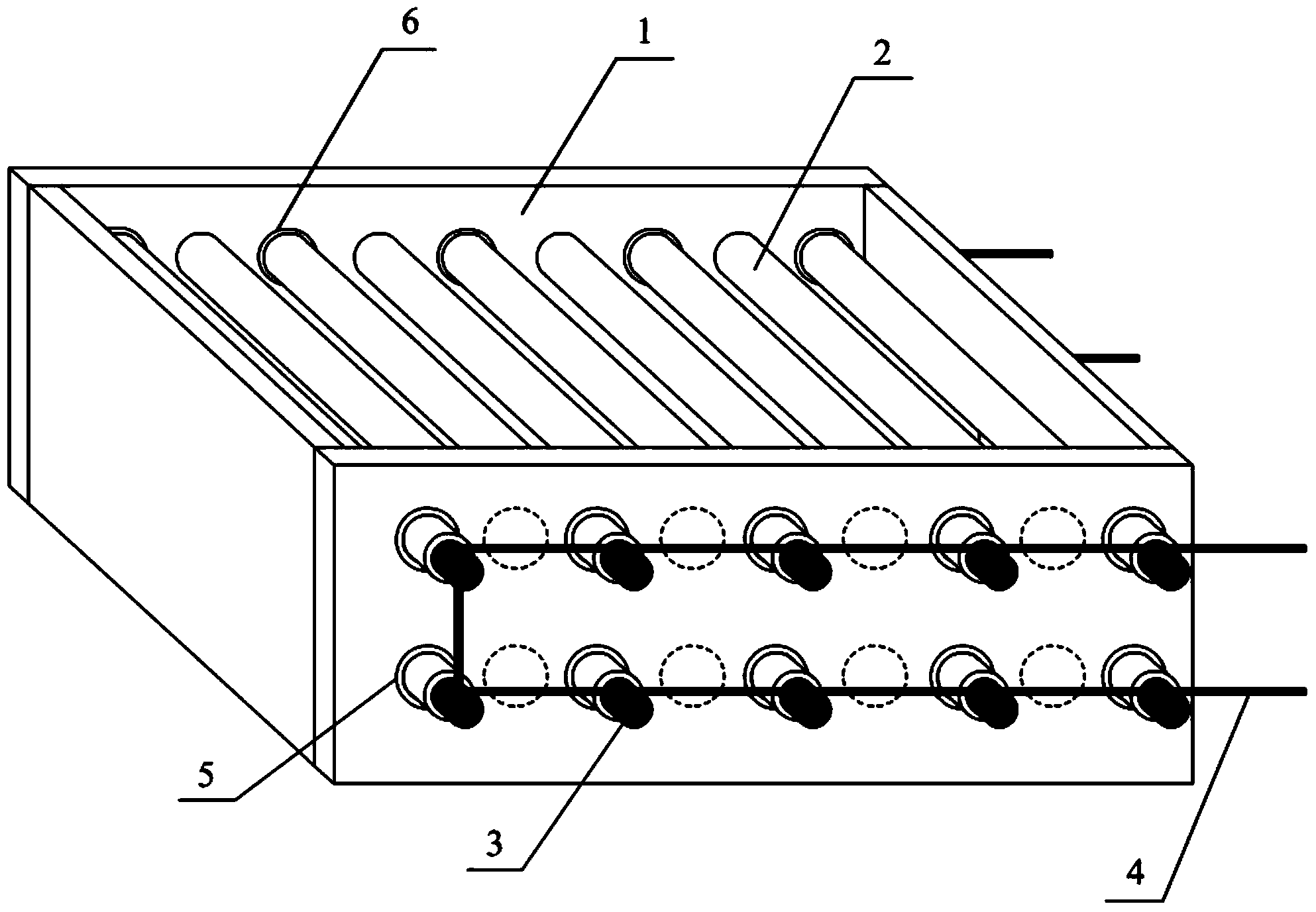

[0031] like figure 1 , 2 As shown, the length of the long board insulating substrate is 100cm, the width is 50cm, and the thickness is 1cm, the length of the short board insulating substrate is 50cm, the width is 50cm, and the thickness is 1cm, and 2 rows of holes are opened on the long board insulating substrate. The hole diameter is 6.5mm, and the horizontal spacing of the holes is 10mm. A slot hole is processed in the middle of the two horizontal holes corresponding to the inner surface of the long board surface insulation substrate. The slot hole corresponds to the hole position on the other side of the long board surface insulation substrate. . Insert the medium tube into the hole, and insert the sealed end of the medium tube into the slot hole on the inner surface of the insulating substrate on the other side of the long board and paste it to connect and fix it. cloth pattern. Among them, the dielectric board is made of polytetrafluoroethylene, and the four dielectric...

Embodiment 2

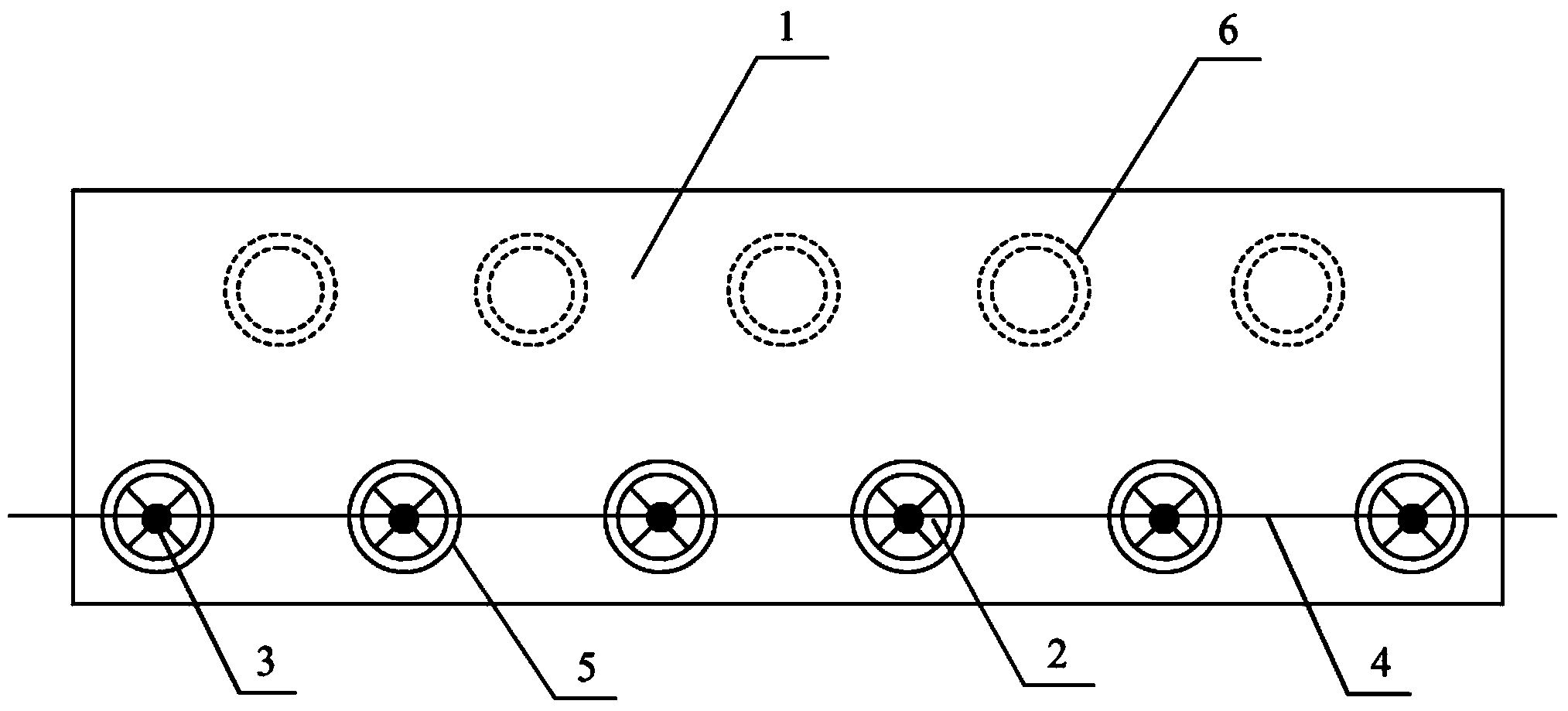

[0033] like image 3 As shown, the length of the long board insulating substrate is 80cm, the width is 40cm, and the thickness is 1cm, the length of the short board insulating substrate is 40cm, the width is 40cm, and the thickness is 1cm, and a row of holes is opened on the long board insulating substrate. The hole diameter is 5.5mm, the horizontal spacing of the holes is 8mm, the height difference between a row of holes on the two long board insulating substrates is 8mm, and the inner surface of the long board insulating substrate on one side corresponds to the midpoint of the two holes A slot hole is set at a position 8mm directly above the board, which corresponds to the hole position on the insulating substrate on the other side of the long board. Insert the medium tube into the hole, and insert the sealed end of the medium tube into the slot hole on the inner surface of the insulating substrate on the other side of the long board and paste and connect them. The dielectri...

Embodiment 3

[0035] like Figure 4As shown, the length of the long board insulating substrate is 60cm, the width is 30cm, and the thickness is 1cm, the length of the short board insulating substrate is 30cm, the width is 30cm, and the thickness is 1cm, and two rows of holes are opened on the long board insulating substrate. The diameter of the holes is 10mm, and the horizontal spacing of the holes is 15mm. In each row of holes on the same long board, other holes are opened 6mm above or directly below the midpoint of the adjacent holes, and other holes form another row of horizontal holes. , the two rows of holes form a symmetrical structure of dislocation up and down. On the inner surface of the long board insulating substrate, a slot hole is processed at the midpoint of every two horizontal holes, and the slot hole is symmetrical to the position of the hole on the other long board insulating substrate. Insert the medium tube into the hole, and insert the sealed end of the medium tube int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com