Nitrobenzene separator with nitrobenzene layered interface regulating device

An interface adjustment, nitrobenzene technology, applied in the direction of liquid separation, separation method, grease/oily substance/float removal device, etc., can solve the problem of increasing energy consumption and operating cost of nitrobenzene wastewater treatment, nitrobenzene separator The problems of poor separation effect and increased steam usage can shorten the residence time, shorten the sedimentation distance, and improve the separation purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

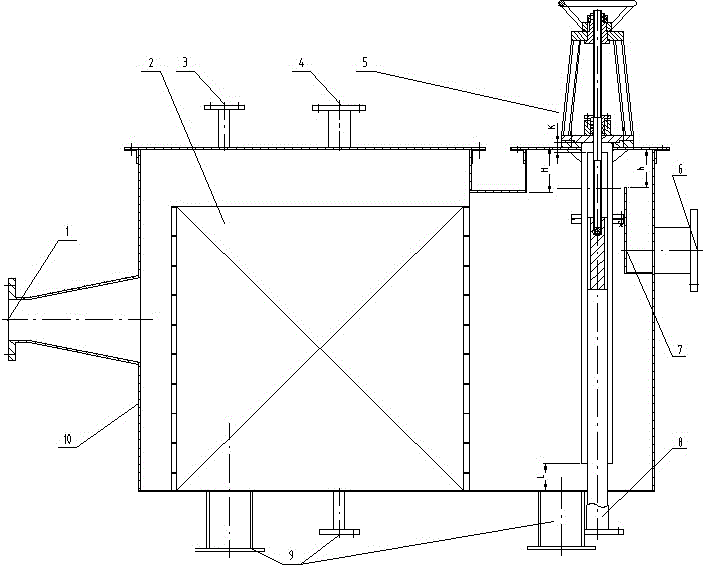

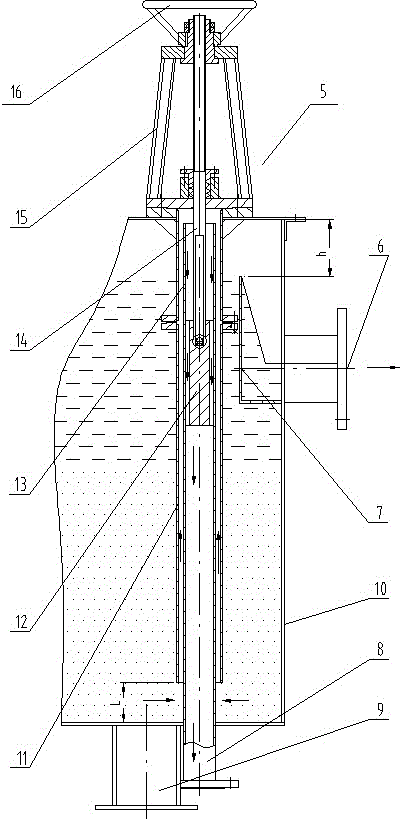

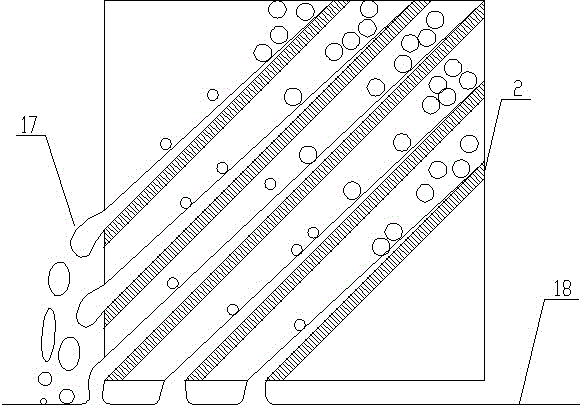

[0017] see Figure 1 ~ Figure 3 , the volume of the present embodiment is 1.66m3, and it comprises housing 10, corrugated plate filler 2, phase weir device 5 and dividing plate 7, is used for adjusting the position of nitrobenzene delamination interface 18, the middle of described housing 10 The feed port 1 is sealed and connected, the water outlet 6 is set above the housing 10, and the nitrobenzene outlet 8 is set below, the water outlet 6 and the nitrobenzene outlet 8 are located opposite the feed port 1 and below the water outlet 6 of the housing 10 An observation port is provided, a nitrogen inlet 3 and an exhaust port 4 are respectively arranged on the top surface of the housing 10, and a cleaning port 9 is arranged on the bottom surface of the housing 10, the nitrogen inlet 3 is sealed and connected with the nitrogen gas source, and the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com