Automatic separation and detection device for idler wheels

A technology of automatic sorting and detection device, applied in sorting and other directions, can solve the problems of increasing the workload of operators, high labor intensity of operators, low product sorting efficiency, etc., to achieve high product sorting efficiency and reduce labor intensity. , the effect of saving testing costs

Active Publication Date: 2015-03-04

SUZHOU XINHAO BEARING

View PDF6 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1. Operators have high labor intensity and low production efficiency

Each inspection process requires manual inspection by the operator, which increases the workload of the operator, reduces production efficiency, and may cause unnecessary losses due to improper operation by the operator.

[0006] 2. Product sorting efficiency is low

Each parameter of each workpiece needs to be tested, resulting in slow workpiece detection speed and reduced production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

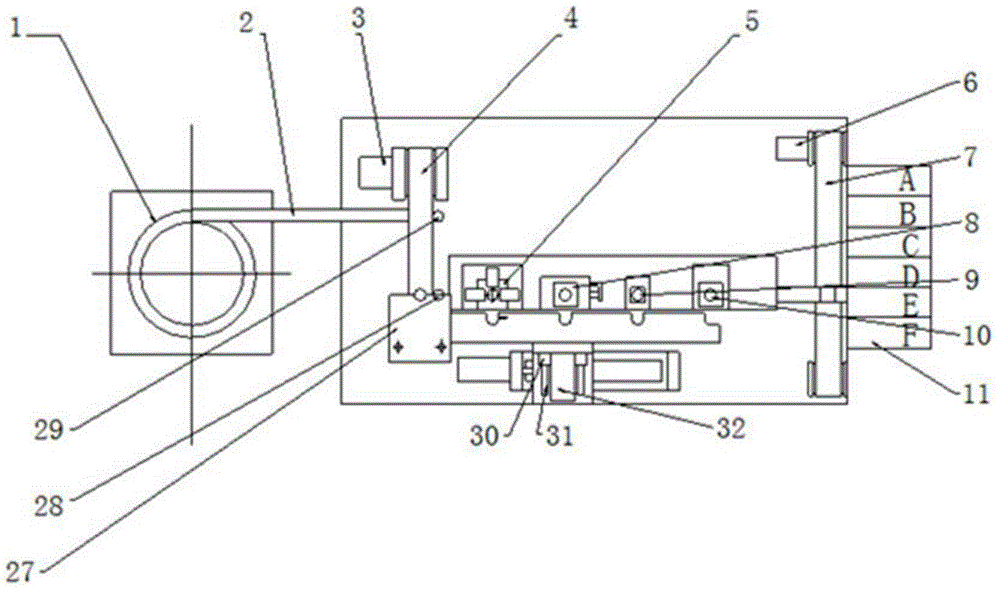

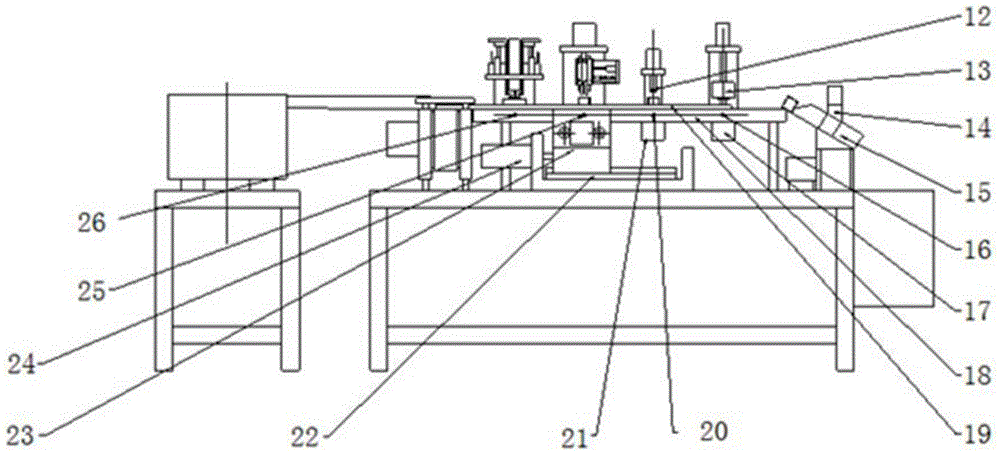

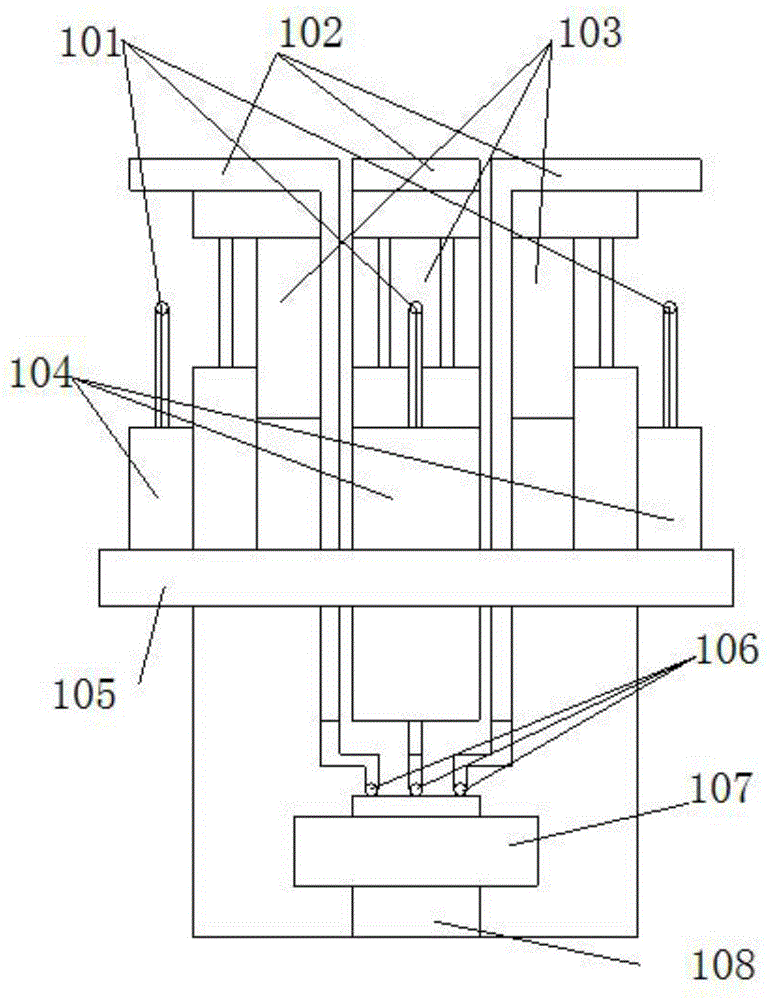

[0046] See figure 1 , figure 2 , the present invention provides a kind of roller automatic sorting detection device, it comprises:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

The invention relates to the technical field of machine manufacturing, and particularly relates to an automatic separation and detection device for idler wheels. The automatic separation and detection device comprises a detection and separation mechanism, a grouping mechanism and a controller, wherein the controller is used for controlling the detection and separation mechanism and the grouping mechanism to work; a feeding drive mechanism is used for driving a delivery sheet to convey to-be-detected idler wheels to the measurement positions which correspond to a height excircle measurement device, an inner diameter separation device, a crack separation device and a hardness separation device for measuring respectively; and a grouping motor is used for driving a grouping conveyer belt to convey grouping channels to the positions corresponding to grouping material boxes. Through implementation of the automatic separation and detection device, feeding, detecting and separating of the to-be-detected idler wheels to final grouping are fully automatically finished; the automatic degree of the product is effectively improved; the labor intensity of the operating personnel is reduced; and the production efficiency and the product yield are improved.

Description

technical field [0001] The invention relates to the technical field of mechanical manufacturing, in particular to a roller automatic sorting and detection device. Background technique [0002] Roller bearings are widely used in industrial production. The outer ring of roller bearings adopts full complement cylindrical roller bearings with thicker outer ring walls. Face to face. With this outer ring, the roller can roll directly on the raceway and can withstand heavy loads and shock loads. Roller bearings are divided into guide rail roller bearings, bolt support roller bearings, ball roller bearings, etc. The quality of the rollers in roller bearings is crucial to the quality of the bearings. [0003] In the manufacturing process of rollers, due to problems such as slag inclusions in raw materials or loose materials, defects such as cracks and trachoma will occur after the rollers are formed. In order to ensure the quality of roller products and reduce potential safety haz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): B07C5/06B07C5/344B07C5/36

Inventor 崔维军

Owner SUZHOU XINHAO BEARING

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap