Manufacturing method of polyurethane polishing pad

A polishing pad and polyurethane technology, applied in the manufacture of tools, metal processing equipment, abrasives, etc., can solve the problems of complicated process, high difficulty, and insufficient effect, and achieve process energy saving, increase hardness and water permeability, high hardness and durability The effect of grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

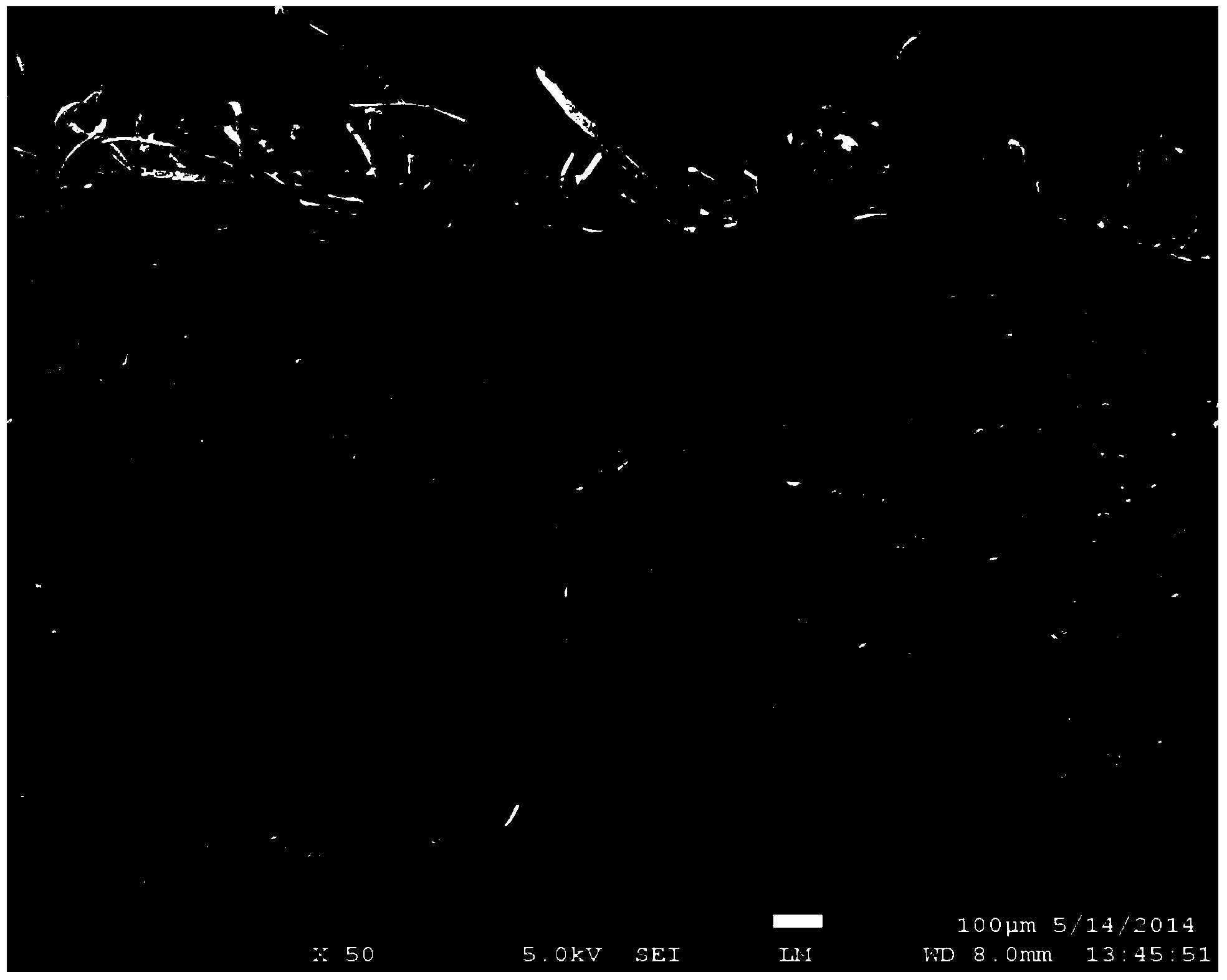

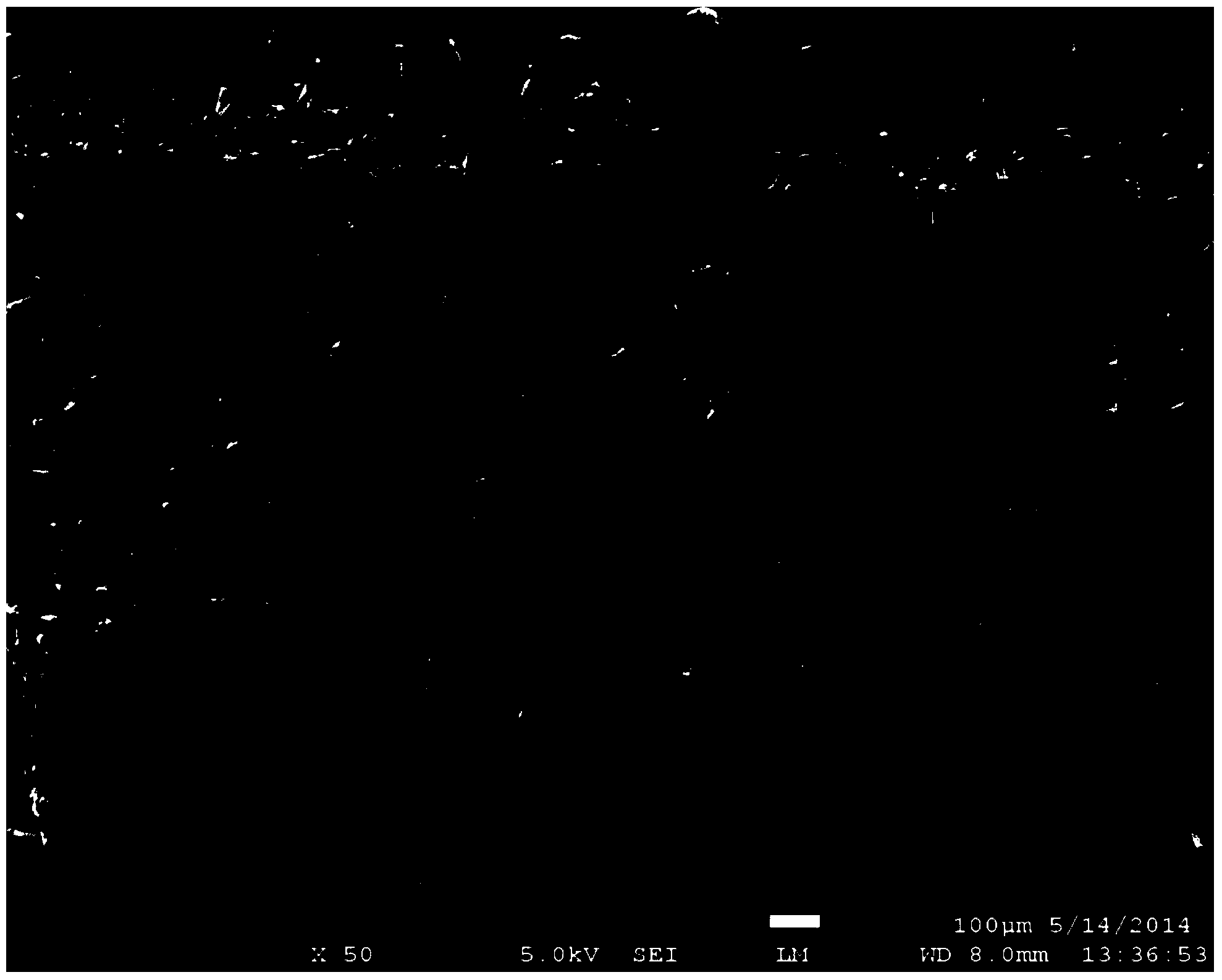

Image

Examples

Embodiment 1

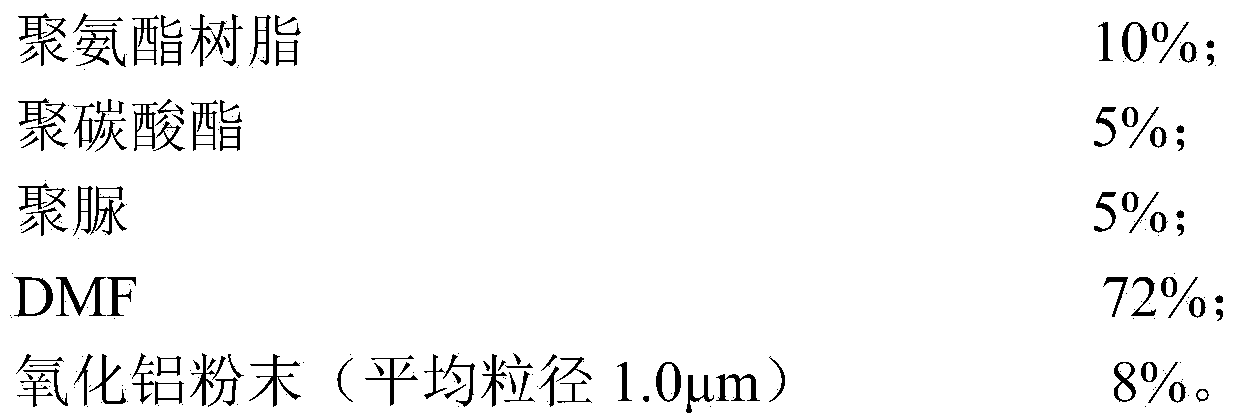

[0042] The raw materials and weight percentages of each component in the soaking liquid are:

[0043] Polyurethane resin 12.8%;

[0044] DMF 87.2%.

[0045] Under room temperature, 3.0mm is thick, and the polyester non-woven fabric of 600 grams is put into by 12.8wt% polyurethane resin and 87.2wt% DMF in the polyurethane resin dipping solution that obtains after mixing and stirring, under the extrusion of metal roller The polyurethane resin impregnation solution is fully immersed in the polyester non-woven fabric, then taken out, after scraping off the excess polyurethane resin impregnation solution on the surface of the polyester non-woven fabric with a scraper, put it into a water tank for pre-coagulation for 10 minutes ( When performing pre-coagulation in water, control the mass percentage of DMF in the water to ≤2%), take it out, and directly send it to an oven at 150°C for 22 minutes to dry and dry it, and then you can get a product with good water permeability, hardness...

Embodiment 2

[0049] The raw materials and weight percentages of each component in the soaking liquid are:

[0050] Polyurethane resin 5%;

[0051] DMF 95%.

[0052] At room temperature, put 4.0mm thick polyester non-woven fabrics with a weight of 900 grams into the polyurethane resin impregnation solution obtained by mixing and stirring 5wt% polyurethane resin and 95wt% DMF, and press the metal roller to make the polyurethane The resin impregnation solution is fully immersed in the polyester non-woven fabric, and then taken out, after scraping off the excess polyurethane resin impregnation solution on the surface of the polyester non-woven fabric with a scraper, put it into a water tank loaded with water for pre-coagulation for 5 minutes (in water When performing pre-condensation, control the mass percentage of DMF in the water to ≤2%), take it out, and directly send it to an oven at 100°C for 50 minutes to dry and dry it to obtain polyurethane polishing with good water permeability, hard...

Embodiment 3

[0055] The raw materials and weight percentages of each component in the soaking liquid are:

[0056] Polyurethane resin 20%;

[0057] DMF 80%.

[0058] At room temperature, put 2.0mm thick polyester non-woven fabric with a weight of 300 grams into the polyurethane resin impregnation solution obtained by mixing and stirring 20wt% polyurethane resin and 80wt% DMF, and press the metal roller to make the polyurethane The resin impregnation solution is fully immersed in the polyester non-woven fabric, and then taken out, after scraping off the excess polyurethane resin impregnation solution on the surface of the polyester non-woven fabric with a scraper, put it into a water tank loaded with water for pre-coagulation for 10 minutes (in water When performing pre-coagulation, control the mass percentage of DMF in the water to ≤2%), take it out, and directly send it to an oven at 180°C for 15 minutes to dry and dry it for 15 minutes to obtain polyurethane polishing with good water pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water permeability | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Water permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com