Composite anaerobic ammonia oxidation reaction process and device based on granule sludge and biological films

A technology of anaerobic ammonium oxidation and granular sludge, which is applied in the field of compound anaerobic ammonium oxidation reaction process and equipment, can solve the problems of weak recovery ability, impact resistance and poor stability, achieve strong recovery ability and save floor space , the effect of reducing operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

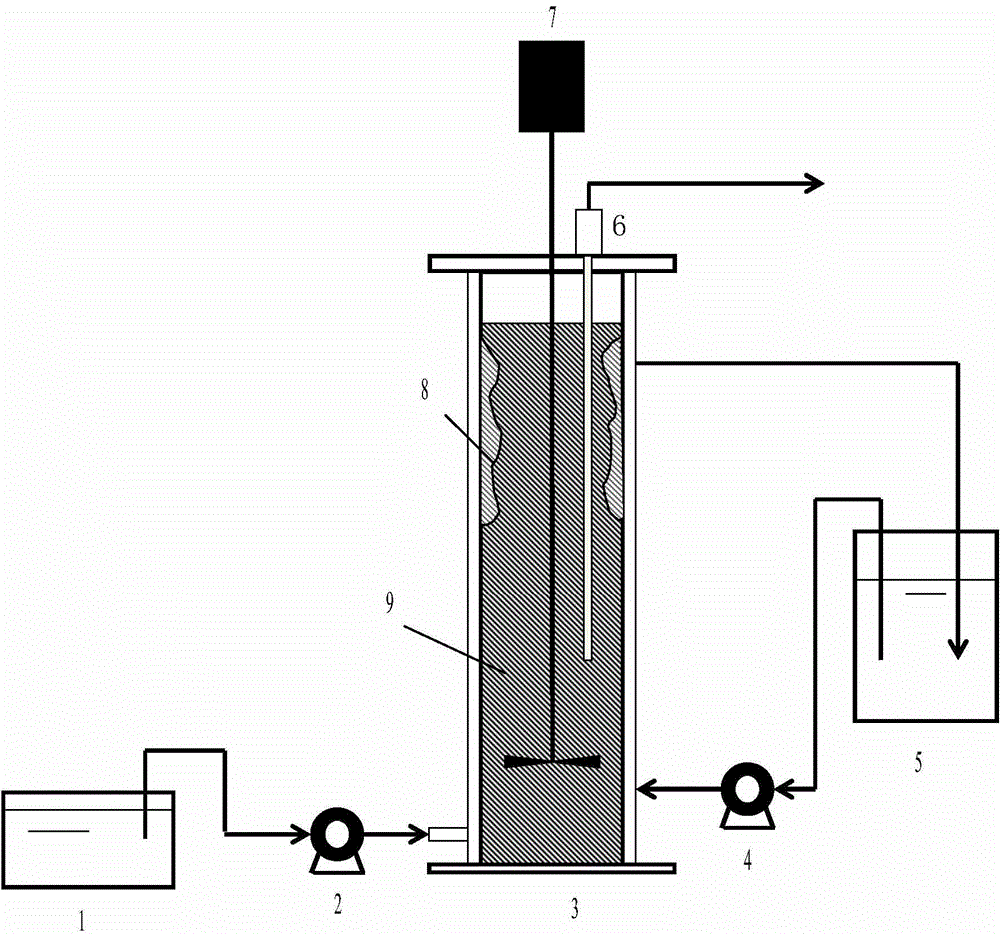

[0017] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0018] The process principle of the present invention is: the main body of the reactor is inoculated with flocculent sludge, and the anaerobic ammonium oxidation granular sludge is gradually formed by stirring to increase the hydraulic cutting force and adding inorganic salts to form crystal nuclei; the reactor adopts sequence batch The operation mode of the type reactor is to realize reasonable dilution of the influent containing high concentration of ammonia nitrogen by adjusting the drainage ratio, so that the matrix concentration in the reactor is within an appropriate range and does not cause inhibition of anaerobic ammonium oxidation; further , to cultivate anammox biofilm on the inner wall of the reactor to further increase the sludge concentration in the reactor.

[0019] Compared with granular sludge, biofilm has a thicker biological st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com