Preparation method for synthesizing polysiloxane neutralizing agent by using alkaline process

A technology of polysiloxane and terminal siloxane, which is applied to the preparation of alkali-synthesized polysiloxane neutralizer and the preparation field of polysiloxane neutralizer, can solve the problem of inability to obtain end-capped products, neutralization Long time, poor compatibility and other problems, to achieve the effects of easy promotion and industrialization, shortened neutralization time, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

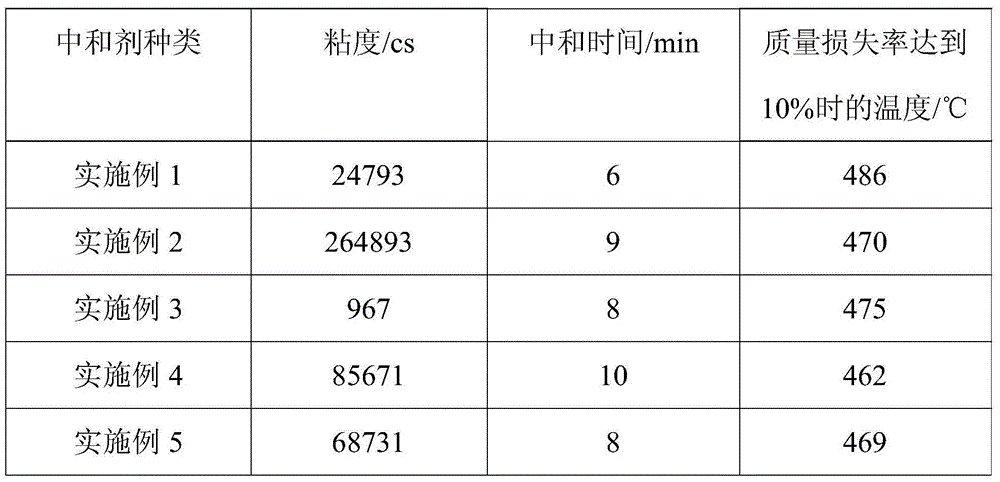

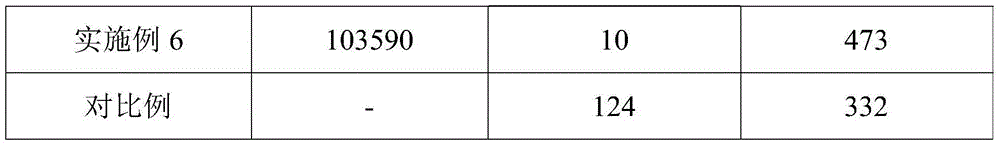

Embodiment 1

[0027] Add 100 parts of phosphoric acid with a mass fraction of 88% and 900 parts of hydroxyl-terminated linear products in the flask, start stirring and heat up at a stirring speed of 220rpm, control the temperature at 110°C to dehydrate until transparent, and dehydrate for 12 minutes to obtain silicon-based phosphoric acid Esters, the viscosity of silicon-based phosphate was measured with a Brookfield viscometer.

[0028] The prepared silicon-based phosphate was neutralized with dimethylsiloxane, and the time required for neutralization was recorded, and 10 mg of dimethylsiloxane was weighed for thermogravimetric testing.

Embodiment 2

[0030] Add 10 parts of phosphoric acid with a mass fraction of 85% and 110 parts of hydroxyl-terminated linear products in the flask, start stirring and heat up at a stirring speed of 200 rpm, control the temperature at 100°C to dehydrate until transparent, and dehydrate for 20 minutes to obtain silyl phosphoric acid Esters, the viscosity of silicon-based phosphate was measured with a Brookfield viscometer.

[0031] The prepared silicon-based phosphate was neutralized with dimethylsiloxane, and the time required for neutralization was recorded, and 10 mg of dimethylsiloxane was weighed for thermogravimetric testing.

Embodiment 3

[0033] Add 100 parts of phosphoric acid with a mass fraction of 98% and 600 parts of hydroxyl-terminated linear products in the flask, start stirring to raise the temperature, the stirring speed is 250rpm, control the temperature at 120°C to dehydrate until transparent, and the dehydration time is 8 minutes to prepare silicon-based phosphoric acid Esters, the viscosity of silicon-based phosphate was measured with a Brookfield viscometer.

[0034] The prepared silicon-based phosphate was neutralized with dimethylsiloxane, and the time required for neutralization was recorded, and 10 mg of dimethylsiloxane was weighed for thermogravimetric testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com