High-oil-resistance ethylene propylene diene monomer rubber composition

A technology of EPDM rubber and oil resistance, applied in the rubber field, can solve problems such as poor oil resistance, and achieve the effect of improving oil aging resistance and good oil resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

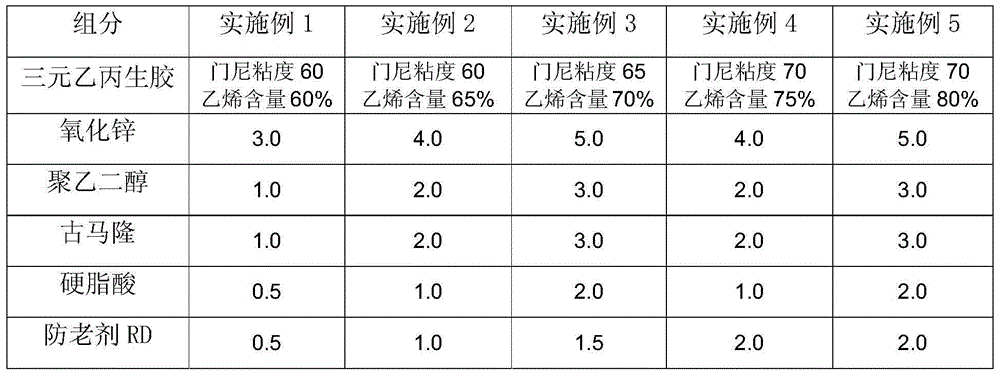

[0012] Embodiment of high oil resistance EPDM composition:

[0013] In the present invention, the EPDM rubber with a Mooney viscosity of 60-70 and an ethylene content of 60%-80% is selected, and the potter's clay with an oil absorption value less than 30ml / 100g and silicon oxyhydroxide is used.

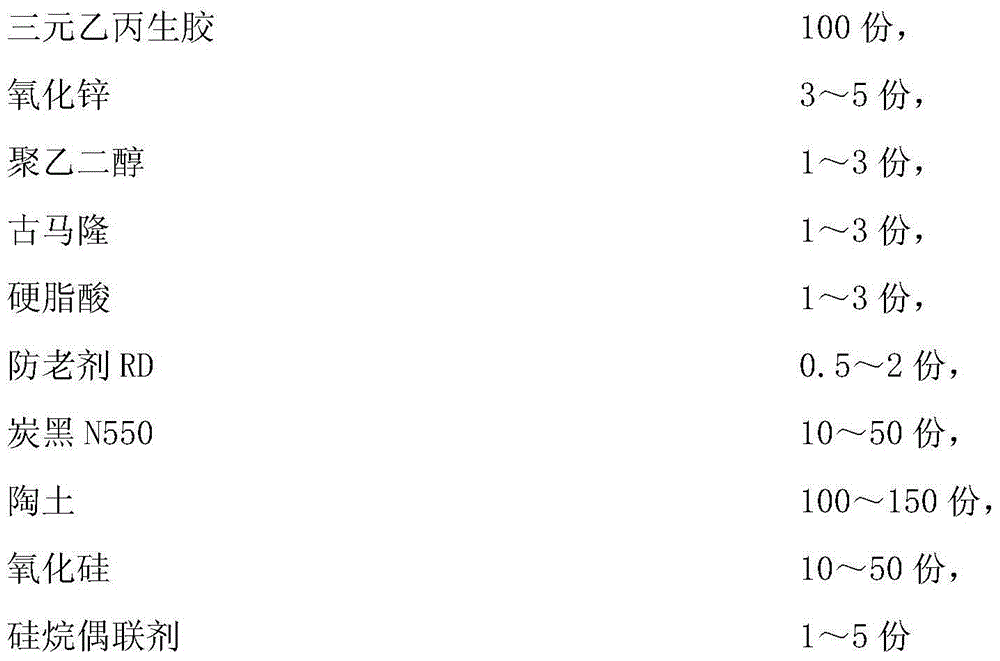

[0014] In parts by mass:

[0015]

[0016]

[0017] According to the raw materials in the embodiment formula, the film is made into a film for testing and detection, and the properties of the high oil-resistant EPDM rubber are as follows:

[0018]

[0019]

[0020] Use EPDM rubber with a Mooney viscosity of 60-70 and an ethylene content of 60%-80%. EPDM rubber with surface-modified clay and silicon oxide instead of part of carbon black as reinforcing agent, resistant to engine oil aging condition 3# engine oil 125℃×72h, hardness decreased within 15%, tensile strength decreased within 25%, The volume expansion is within 15%, and the oil aging resistance performance is obv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil absorption value | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com