Low-viscosity ultra-low temperature two-way wide temperature brine

A refrigerant and ultra-low temperature technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of metal material corrosion, poor heat transfer performance, affecting heat transfer effect, etc., to prolong the service life and prevent volatilization loss , good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

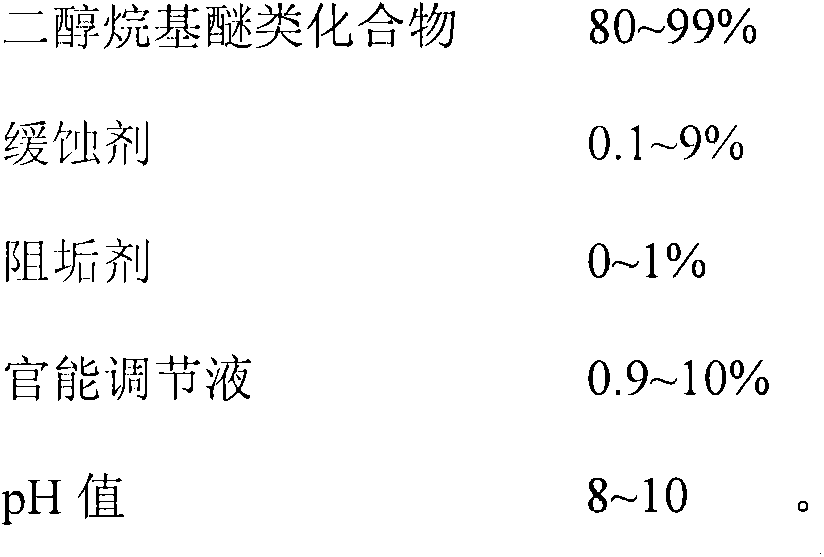

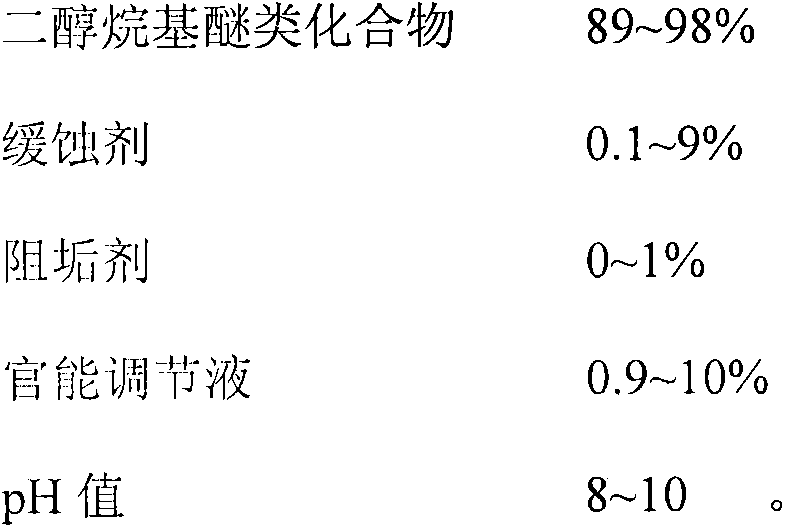

Method used

Image

Examples

Embodiment 1

[0019] The weight composition of the refrigerant is as follows: 95% of diethylene glycol methyl ether, 0.05% of sodium benzoate, 0.1% of sodium molybdate, 2% of sodium nitrate, 0.1% of benzotriazole and 2.75% of water. The freezing point of the refrigerant is below -80°C, and the boiling point is above 190°C. It can be used as a refrigerant in the environment of -40-185°C. It is non-toxic, non-volatile, non-flammable, non-scaling, and non-mildew. It does not corrode metal, has good fluidity at low temperature, and is convenient for circulation and transportation.

Embodiment 2

[0021] The weight composition of the refrigerant is as follows: 88% of dipropylene glycol methyl ether, 2% of sodium nitrite, 0.6% of polyaspartic acid, 5% of ethanol, and 4.4% of water. The freezing point of the brine is below -80°C, the boiling point is above 185°C, the viscosity is 72.7cP at -70°C, and it can be used at an ambient temperature of -60 to 150°C. Non-toxic, non-volatile, non-flammable, non-scaling, non-mildew, non-corrosive to metals, good low temperature fluidity, can be widely used in food, chemical, pharmaceutical and other fields.

Embodiment 3

[0023] The weight composition of the refrigerant is as follows: 95% of diethylene glycol methyl ethyl ether, 1% of sodium molybdate, 1.5% of sodium nitrate, 0.1% of benzotriazole, 0.4% of S-carboxyethyl thiosuccinic acid, 2% of water %. The freezing point of the brine is below -80°C, the boiling point is above 176°C, the viscosity at -75°C is 68.88cP, and it can be used at the ambient temperature of -75-170°C. Non-toxic, non-volatile, non-flammable, non-scaling, non-mildew, non-corrosive to metals, good fluidity at low temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com