Half-cycle self-correction anti-bending drilling tool

A self-correcting, half-cycle technology, used in drill bits, drill pipes, drill pipes, etc., can solve problems such as easy bending of drilling holes, avoid economic losses, and improve drilling quality and drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

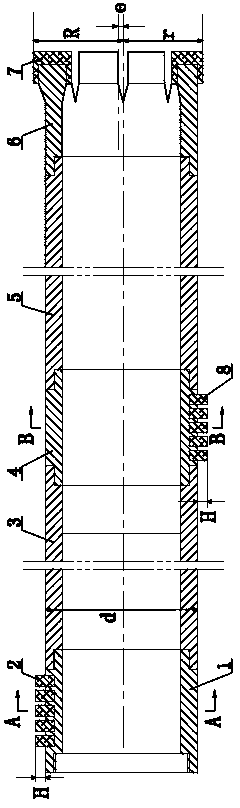

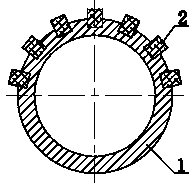

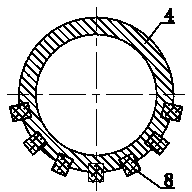

[0020] Such as Figure 1-4 As shown, the semi-period self-correcting anti-bending drilling tool includes a drill bit and an outer tube, the outer tube is composed of upper and lower core tubes 3, 5, the upper end of the upper core tube 3 is connected with an upper eccentric member 1, and the A matrix-shaped alloy upper eccentric body 2 is evenly inlaid and welded on the half circumference of the upper eccentric member 1, and a lower eccentric member 4 is connected between the upper and lower core tubes 3 and 5, and half of the lower eccentric member 4 A matrix alloy reverse eccentric body 8 is evenly inlaid and welded on the circumferential surface, and the two semi-circumferential surfaces of the alloy upper eccentric body 2 and the alloy reverse eccentric body 8 are respectively arranged with a difference of 180 degrees. The drill bit is an eccentric drill bit connected to The lower end of the lower core tube 5 is composed of a supporting rigid body 6 and an eccentric grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com