Micro spherical type short coherent point diffraction interference measurement system and method

A point diffraction interferometry and measurement system technology, applied in the field of microspherical short coherent point diffraction interferometry systems, can solve the problems affecting measurement accuracy, poor contrast of interference fields, etc., to achieve high measurement accuracy, increase coverage area, avoid multiple the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

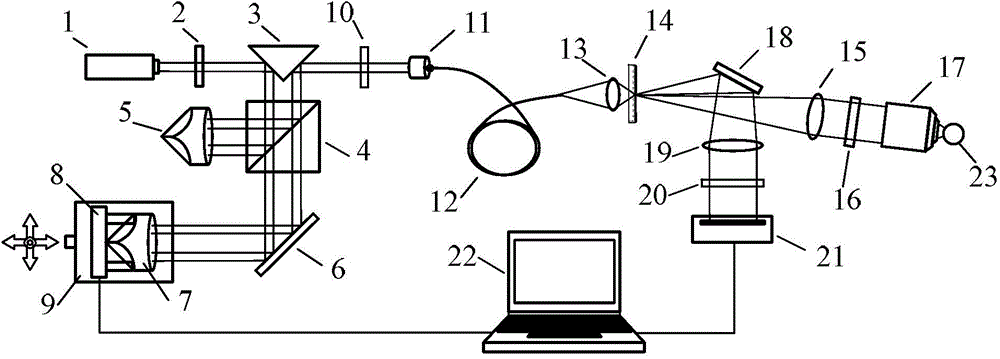

[0030] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the microspherical surface type short coherence point diffraction interferometry system described in this embodiment, it comprises short coherence laser 1, first λ / 2 wave plate 2, right-angle reflector 3, polarization beam splitter prism 4, first angle Axicon prism 5, first plane mirror 6, second corner aconite prism 7, PZT phase shifter 8, delay platform 9, second λ / 2 wave plate 10, fiber coupling mirror 11, single-mode polarization-maintaining fiber 12, converging lens 13 , pinhole mirror 14, first collimator lens 15, λ / 4 wave plate 16, microscope objective lens 17, second plane mirror 18, second collimator lens 19, polarizer 20, area array CCD21 and computer 22,

[0031] The outgoing laser light of the short coherent laser 1 enters the right-angle reflector 3 through the first λ / 2 wave plate 2, and the light incident surface of the right-angle reflector 3 is perpendicular t...

specific Embodiment approach 2

[0039] Specific implementation mode two: the following combination figure 1 Describe this embodiment mode, this embodiment mode will further illustrate embodiment one, described first collimating lens 15, λ / 4 wave plate 16, microscopic objective lens 17 are coaxial with tested microsphere 23;

[0040] The focal point of the first collimator lens 15 coincides with the pinhole of the pinhole mirror 14 .

specific Embodiment approach 3

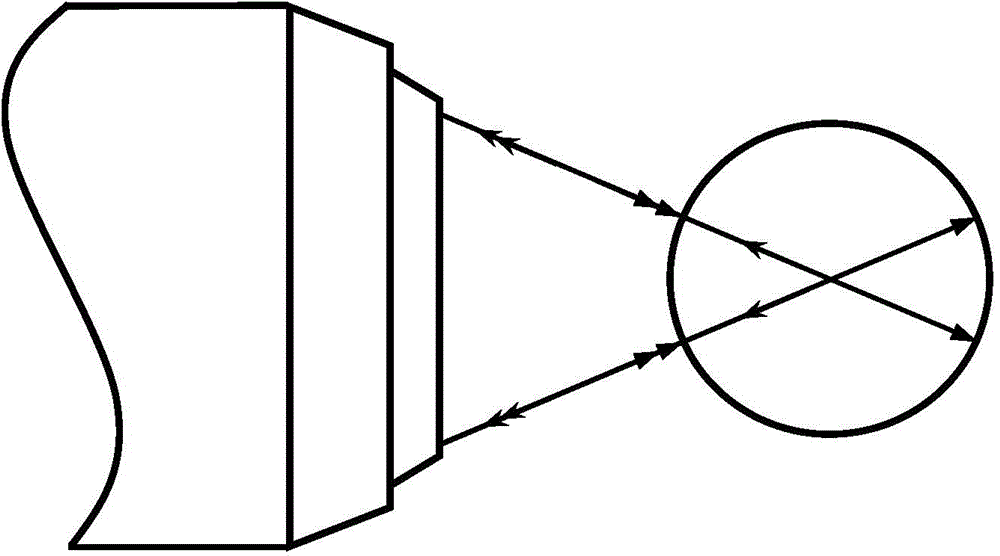

[0041] Specific implementation mode three: the following combination figure 1 This embodiment will be described. This embodiment will further describe Embodiment 1 or 2. The center of the measured microsphere 23 is located at the center of the light beam emitted by the microscopic objective lens 17 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com