Experimental device for fine mechanical flow field measurement for fluid

An experimental device and fluid machinery technology, which is applied in the field of experimental devices for fine measurement of fluid machinery flow field, can solve the problems of difficult torsional flow field measurement, complicated component replacement, and difficult fluid storage, so as to maintain consistent thermophysical properties and calculate precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

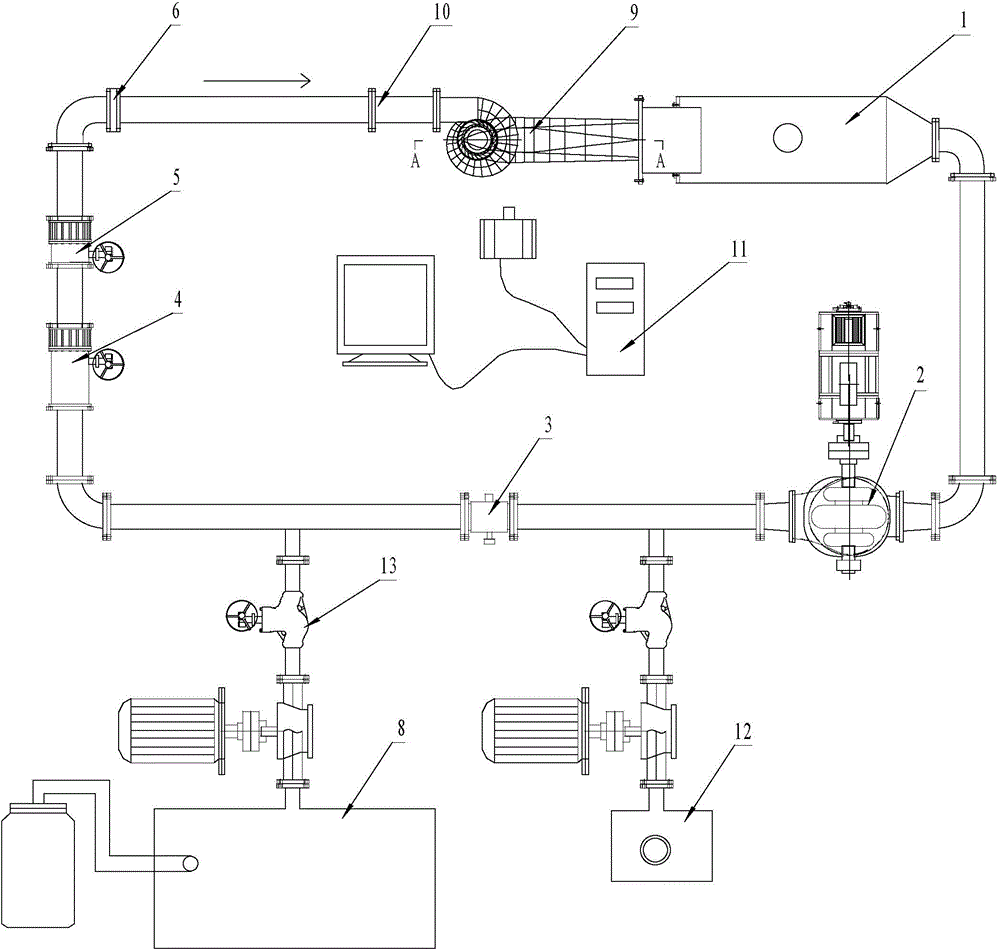

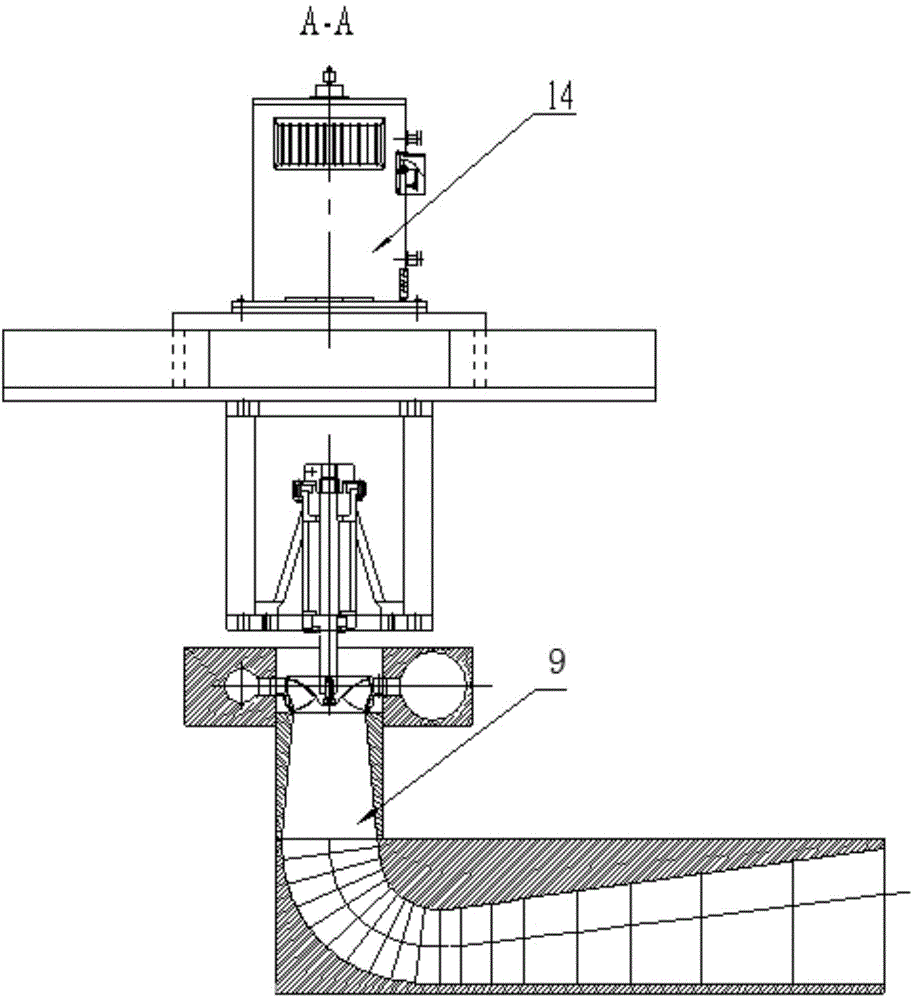

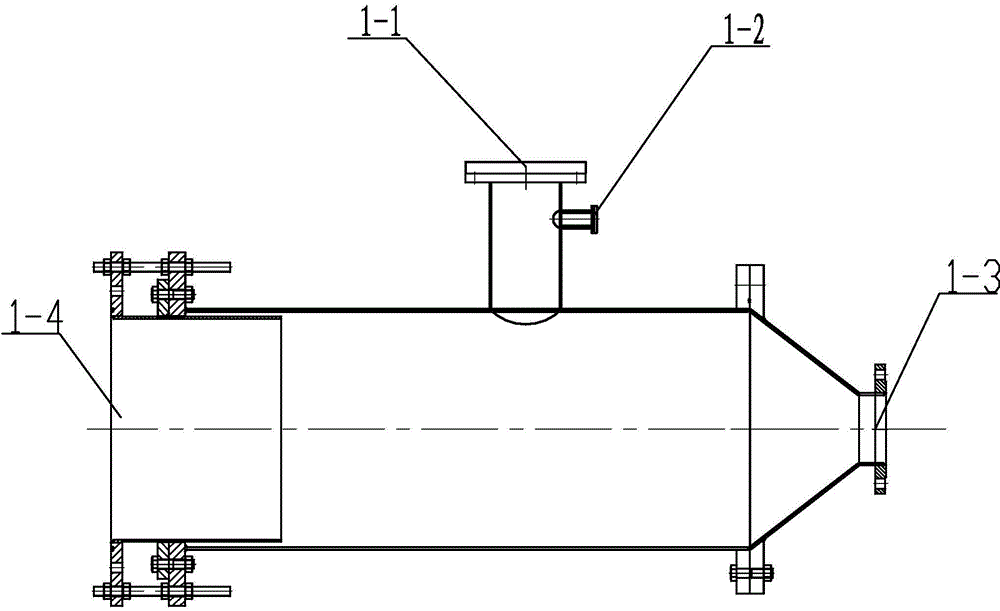

[0021] Specific implementation mode 1: Combination figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 To explain this embodiment, the experimental device for the fine measurement of the flow field of fluid machinery in this embodiment includes a tail water tank 1, a water pump group 2, a flow monitoring device, a steady flow flange 6, a fluid storage system 8, and a model to be measured. Device 9, expansion joint 10, flow field fine test system 11, tracer particle addition mechanism 12 and dynamometer 14, tail water tank 1, water pump group 2, flow monitoring device, steady flow flange grid 6, expansion joint 10 It is connected with the model device 9 to be measured to form a closed loop detection channel in sequence. The tracer particle adding mechanism 12 is installed between the water pump group 2 and the flow monitoring device, the fluid storage system 8 is connected with the flow monitoring device, and the flow field is refined test system. 11 is arrange...

specific Embodiment approach 2

[0033] Specific implementation manner two: combination figure 1 To describe this embodiment, the fluid storage system 8 and the model device 9 to be measured in this embodiment are both transparent model devices to be measured made of organic glass. With this arrangement, the outer surfaces of all parts of the model device 9 to be measured are designed to be hexahedral or have parallel surfaces, and the outer surfaces of the parts are polished and kept smooth. Avoid air bubbles on the joint surface. The other composition and connection relationship are the same as in the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination figure 1 To describe this embodiment, the flow field refinement test system 11 of this embodiment is a particle image velocimetry, a laser Doppler velocimetry, or a laser induced fluorescence. With this setting, the whole system can realize the comprehensive functions of flow adjustment, damping adjustment, steady flow adjustment, cavitation degree adjustment, forward and reverse adjustment, automatic addition of tracer particles, fluid recovery and flow field measurement. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com